-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RESTO My Carbon Fiber X4's

- Thread starter Matt Braley

- Start date

- Status

- Not open for further replies.

I broke out some OEM rave parts today. These are from early 96 and I like the red bellows and off white pistons. I thought this was gonna be the build that got the Rave-Link I've been saving but the bracket does not fit. I just made holes in the caps so I can see them open and close.

Even the springs and retainer clips were new in the bag. I really like the way it turned out.

I got some more plumbing done today. On the way home I was thinking I should have used the 1/4" orange line to the pisser. I may redo that. I've used a Factory Pipe billet filter to distribute the incoming water.

Even the springs and retainer clips were new in the bag. I really like the way it turned out.

I got some more plumbing done today. On the way home I was thinking I should have used the 1/4" orange line to the pisser. I may redo that. I've used a Factory Pipe billet filter to distribute the incoming water.

CReynoldsMIZ

Well-Known Member

What does the ravelink do?

Yeah I guess I do have a thing for the old Canadian performance parts. The other hull is the Odyssey with the Odyssey sponsons and the Bazooka pipe........now that's Canadian!

I have a aftermarket lightweight drive shaft but it's 17" and looks to be about an inch short. Yes I know they are in mm officially but my redneck tape is only in American. I'll just have to use an 18" one. I think this one will fit my GSX though so I'm still happy to have it.

I have a aftermarket lightweight drive shaft but it's 17" and looks to be about an inch short. Yes I know they are in mm officially but my redneck tape is only in American. I'll just have to use an 18" one. I think this one will fit my GSX though so I'm still happy to have it.

I'll have to look at that tomorrow. A 94XP is not a X4 though I'd be better off measuring from my 97SPX.

Today I picked out a clean 18" drive shaft and a new seal/carrier. I hit it with two new drive shaft bumpers and found a good used oem pto boot with clamps. Now it's time to spend this new Solas pump. This thing is nice! I put a XO(16.5X24) in there and you could not fit a hair in the gap of the stainless steel wear ring.

There is no oil in these just grease

Mated

Now I've dove in to the electrical. I'm plugging in the VTS components outside the hull to make sure things work OK. I have a housing that gives me a clean up and down but would not send a good signal to the gauge. I have "The Gauge Fix" which is a product from the guy who makes and sells "The Trim Fix".

Bird's nest

Today I picked out a clean 18" drive shaft and a new seal/carrier. I hit it with two new drive shaft bumpers and found a good used oem pto boot with clamps. Now it's time to spend this new Solas pump. This thing is nice! I put a XO(16.5X24) in there and you could not fit a hair in the gap of the stainless steel wear ring.

There is no oil in these just grease

Mated

Now I've dove in to the electrical. I'm plugging in the VTS components outside the hull to make sure things work OK. I have a housing that gives me a clean up and down but would not send a good signal to the gauge. I have "The Gauge Fix" which is a product from the guy who makes and sells "The Trim Fix".

Bird's nest

Last edited by a moderator:

Thank you bud. I'm hoping for another productive day tomorrow. Today was cold but I just kept going. Tomorrow is supposed to rain though.

Seadoodoc

Active Member

My point on that Matt was if the hulls were built off maybe a 717 platform and the bottom section is shorter. No way the top deck changes fitment. All the early race boats and hulls were built to suit stand up 787 stroker motors with later adaptation to slant 787. Just trying to some mental historical data logging!  lookin great so far. Anxious for water test or what?

lookin great so far. Anxious for water test or what?

Spimothy Leary

Well-Known Member

this, and the other couple build threads going right now are all so freaking awesome !!!!

nice job so far Matt, love what your doing here.

nice job so far Matt, love what your doing here.

Matt its really easy to drill and tap extra fittings into the factory pipe strainer...Thats what I did on my last build.

Matt did you see the guy had for sale a whole lot of the Big Red factory race Carbon hulls? Months ago. Looked like they were sitting in a backyard for a decade.

Yes I got a lot from that find including my Big Red Racing carbon fiber GSX. The guy is a HX racer that I still keep up with.

here is that measurement pic

Now I have some other good progress to report. Yesterday was rainy but I got the hood put together. I opted for the yellow visor because I need something to tie it in with the rest of the ski. I used silicone to attach it so there were no holes drilled.

Here are the gauges. I have my Racepak on the left that will show exhaust gas temp and RPM. There was not enough room between the other gauges to use both nuts in back so I siliconed the center one in. They fit tight already, I had to open the holes up further with a rat tail file.

I used a little Jap bike brake fluid reservoir to go in the place of the oil tank.

Now this you might really like. I've got the handle bars outfitted. Starting from left to right I have a UMI two button holder then a Racepak screen selection button. On the right side I have a Vilder single button switch and then a UMI angle pull throttle.

Thank you. I just want to finish the assembly because there are a lot of other things I need to be working on. The test and tuning phase can take a while. It wouldn't surprise me if I ended up changing the pipe, carbs, and ignition before it's over. My black and white X4 hit 61 so I MUST blow past that to be where I wanted to be from all this.

Minne thanks for the billet filter thought. My concern is that a bypass would drop the water pressure. They have really small restriction jets(#65 on stinger and wb) to feed. I went with a 75 and a 80 for starters but still......I'm just thinking if I give the water another place to go it's not gonna push through those little jets. That leaves no good place for the case cooler to tie in. With a #115 holding the water back it's just not gonna flow under there too well.

Minne thanks for the billet filter thought. My concern is that a bypass would drop the water pressure. They have really small restriction jets(#65 on stinger and wb) to feed. I went with a 75 and a 80 for starters but still......I'm just thinking if I give the water another place to go it's not gonna push through those little jets. That leaves no good place for the case cooler to tie in. With a #115 holding the water back it's just not gonna flow under there too well.

Brand new Solas nozzles mated to the new Solas pump. New VTS boot with fresh OEM style clamps. I'm done under here for now.

New Outerwear water repelling pre-filters on those ProK's

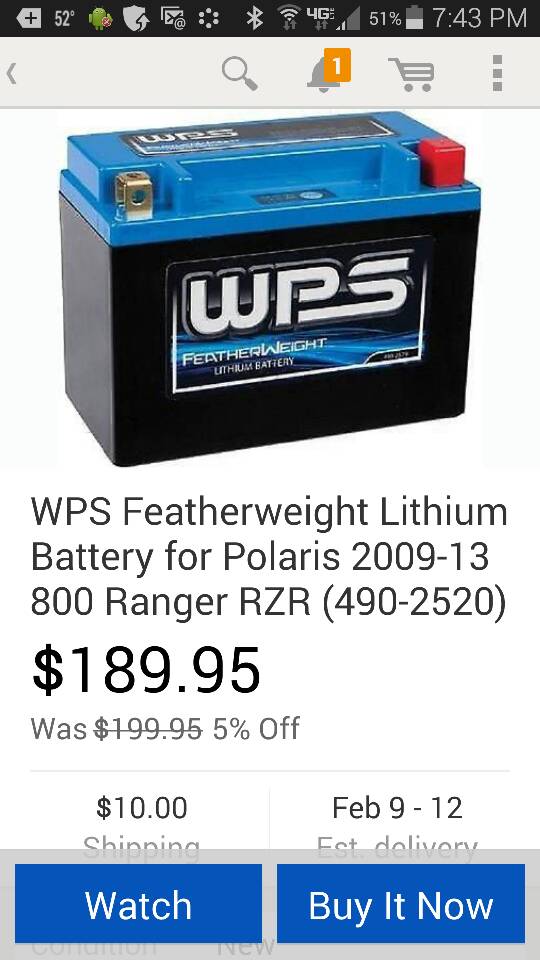

Inside of VTS installed and new orange gel battery. I made a fused power supply for the Racepak.

That old black Westside decal was hiding a couple sins. It was a "well placed sticker" as Spim says haha. I used the location they chose to make a hole to mount a switch that turns the Racepak Hottach on and off. Then I hit it with a fresh orange carbon fiber Westside sticker!

New Outerwear water repelling pre-filters on those ProK's

Inside of VTS installed and new orange gel battery. I made a fused power supply for the Racepak.

That old black Westside decal was hiding a couple sins. It was a "well placed sticker" as Spim says haha. I used the location they chose to make a hole to mount a switch that turns the Racepak Hottach on and off. Then I hit it with a fresh orange carbon fiber Westside sticker!

Last edited by a moderator:

Awesome!!!! Where did you get that orange battery

96 XP800!

Keep the 2 strokes alive!

http://www.ebay.com/itm/360757744697?_trksid=p2059210.m2749.l2649&ssPageName=STRK:MEBIDX:IT

Seadoodoc

Active Member

Seem more sensitive to parasitic drain.. i.e. leaving lanyard on for a week. At 10lbs savings it really makes one consider the 5lbs savings of carbon hood. Certainly does not look as cool as Matts bad arse carbon hood though! Keep pics comming Braley..

- Status

- Not open for further replies.

Similar threads

- Replies

- 23

- Views

- 5,700

- Replies

- 117

- Views

- 19,209

- Replies

- 78

- Views

- 17,079

- Replies

- 15

- Views

- 16,420