If the flame arrestor is missing, you're likely to have to use more choke to get it started, it should still fuel while idling. The WOT and prehaps even mid range will run but likely too lean though, so there's some danger of overheating the piston without the air box (flame arestor).

What was the pop pressure you measured on the PTO carb, same as MAG carb?

Is the carb getting fuel, or is it not fueling the cylinder (there's a difference, if it's not getting fuel it cannot meter fuel to the cylinder)?

How did you determine the PTO carb isn't metering fuel? (I feel for warmth of the spark plug)?

I doubt you can see the fuel by looking down inside the carb at idle speed, the fuel comes from the idle port on the engine side of the butterfly at idle. The large venturi begins to flow only if the throttle is opened maybe 25% or more (hard to test this on a trailer without over revving).

I wonder if perhaps the linkage between the carbs is misadjusted (not synchronized), so maybe the PTO carb butterfly is not in the correct position (closed more than the MAG carb butterfly).

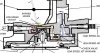

Attached drawing shows all three of the possible fuel flow paths (idle port, Bypass Ports (AKA: Transition ports), Main Venturi) The main venturi doesn't flow until there's a load on the engine while in the water b/c the throttle needs to be open some amount to increase the velocity of air across that big venturi.

How about the main venturi mylar check valve (circled in blue) held by a single screw on the kidney shaped metering plate, it's not bent is it? If the mylar piece doesn't seal flat over the hole and against the metering plate you might experience no fuel at idle speed b/c air will come backwards from the Main Venturi into the metering chamber thus the metering valve might not pop and allow fuel into the chamber at idle.

Also keep in mind, fuel is provided on demand based on vacuum, the metering diaphragm doesn't move inward into the metering arm and pop the inlet valve open unless there's a vacuum signal. If the mylar check valve is damaged then there might not be enough vacuum to operate the metering diaphragm at low speed (such as idle).