Hello. I know this has probably been discussed before but after a quick search I couldn’t find anything. I recently acquired a 1996 gsx which I rebuild the engine on over the winter. Right after ice out I took it out to make sure everything worked and it ran great. Fired right up, idled at 1250-1500 in the water and power felt smooth. A few weeks later I get to the launch and it won’t start. Took the carbs off and gave them a clean and now it is extremely hard to start and will only start with fuel off and once the fuel is turned back on it idles at 2500 rpm in the water. Max rpm is about 6600. Once shut off it immediately will be very difficult to start again. Took the carbs off and ordered rebuild kits from SBT as well as needles and seats from them. After rebuilding mag carb, wetting the needle and filling the entire cavity with wd40, blocking off all ports, and connecting tester to fuel inlet. The fuel pump is leaking from the base where it meets the carb and my pop off test is anywhere from bubbling at 2PSI to a solid pop off at 50PSI. I have made sure to bend the tab with the spring level to the carb body. But not sure why with brand new gaskets and needle and seat I am having such wild fluctuations while also having a leak. TIA for the responses.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carb Fails Pressure And Pop Off Test After Full Rebuild

JC-SUPERJET

Active Member

ALWAYS USE GENUINE AUTHENTIC MADE IN JAPAN MIKUNI SBN KITS.

ONLY USE GENUINE AUTHENTIC MADE IN JAPAN MIKUNI SBN KITS.

ONLY USE GENUINE AUTHENTIC MADE IN JAPAN MIKUNI SBN NEEDLE VALVE KITS.

ONLY USE GENUINE AUTHENTIC MADE IN JAPAN MIKUNI SBN KITS.

ONLY USE GENUINE AUTHENTIC MADE IN JAPAN MIKUNI SBN NEEDLE VALVE KITS.

Good place to get Genuine Mikuni rebuild kit is OSDparts.com

LOL, SBT carb kits... Tell us another joke.

Just giving you are hard time as we see this every Spring, you are not the first and not the last.

Follow this Thread. The Seadoo Carb Rebuild Thread

Just giving you are hard time as we see this every Spring, you are not the first and not the last.

Follow this Thread. The Seadoo Carb Rebuild Thread

I bought the carb kits because this was happening. The jet ski ran perfect and 3 weeks later ran like crap. After some research I decided to buy some carb kits and rebuild them but I was curious if it counts like my issue is due to carbs or if there could be some other cause I am not thinking about. So I’m guessing it sounds like a carb issue to you?Everything you are experiencing is indicative of cheap carb kits.

In your first post you mentioned bubbling while doing a pop off test so definitely need to rebuild the carbs with Mikuni parts but I seen in your last post that ts idling at 2500 rpm in the water, could also be running lean due to air leak. What was the compression before you did the rebuild? Did you do a leak down test before and/or after the rebuild?

Compression is 140 No leak down test was performed but due to the nature of it running fine before hand I would presume there would be no leaks but I could check it. I did not rebuild the engine. It was rebuilt professionally by a local machinist and I got the engine after it had about 20 hours on it and swapped it from a trashed hull that had a spark issue so I got the motor for much cheaper than retail so I have never taken the engine apart. I have tried to spray carb cleaner around the seal on the PTO side with no change in engine rpm. When I remove the plugs after idling at 2500RPM and having the issues described above, They were very wet with fuel as you will see in the pictures below.In your first post you mentioned bubbling while doing a pop off test so definitely need to rebuild the carbs with Mikuni parts but I seen in your last post that ts idling at 2500 rpm in the water, could also be running lean due to air leak. What was the compression before you did the rebuild? Did you do a leak down test before and/or after the rebuild?

Attachments

Ok, just thinking. If it were me, I would probably hold off on the leak down test until after you get the carbs rebuilt, that will most likely fix your issues. If it is still idling high after the carb rebuild maybe consider the leak down test then.

Ok I’ll plan on that. Thank you for all the help.Ok, just thinking. If it were me, I would probably hold off on the leak down test until after you get the carbs rebuilt, that will most likely fix your issues. If it is still idling high after the carb rebuild maybe consider the leak down test then.

Venturian1

Member

The tiny bubbles.... were from the outside of the seat, or the inside? (O-ring or needle) And you used compressed air to blow out the 3 tiny holes

in the venturi? And the restriction orifice in the pto carb return line?

in the venturi? And the restriction orifice in the pto carb return line?

thejuice48

Active Member

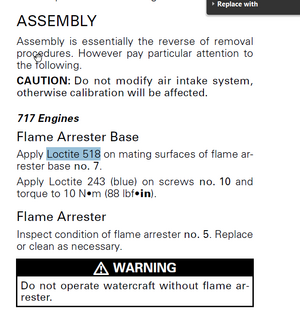

with regard to external leaks...The sbt carb rebuild kits do not include the engine side gaskets nor the flame arrestor mounting gaskets. these are available for separate purchase. reading through the my manual you need both along with loctite on the flame arrestor side.it seems through the years these are upgrades. pop off pressure may be related to the spring replaced when testing pop off pressure. The size you may have replaced may not be the right size so the needle may not seat right to hold the pressure.

As far as I could tell the bubbles were coming from the needle. I did use compressed air as well as carb cleaner to clear all passageways and holes till clear although I didn’t notice any blockages.The tiny bubbles.... were from the outside of the seat, or the inside? (O-ring or needle) And you used compressed air to blow out the 3 tiny holes

in the venturi? And the restriction orifice in the pto carb return line?

I purchased those gaskets separately off of SBT’s website. I also used a small ammount of blue locktite on the carb mounting bolts as well as the bolts on the fuel pump side or both carbs. Needle and seat was 1.5. As far as I could tell that is the correct spec as per the manual.with regard to external leaks...The sbt carb rebuild kits do not include the engine side gaskets nor the flame arrestor mounting gaskets. these are available for separate purchase. reading through the my manual you need both along with loctite on the flame arrestor side.it seems through the years these are upgrades. pop off pressure may be related to the spring replaced when testing pop off pressure. The size you may have replaced may not be the right size so the needle may not seat right to hold the pressure.

thejuice48

Active Member

As far as I could tell the bubbles were coming from the needle. I did use compressed air as well as carb cleaner to clear all passageways and holes till clear although I didn’t notice any blockages.

thejuice48

Active Member

When you're testing pop off, you're supposed to spray a bit of WD40, and then work the spring a couple of times before testing.

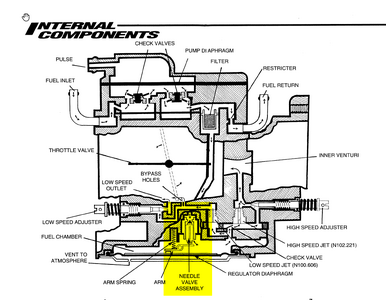

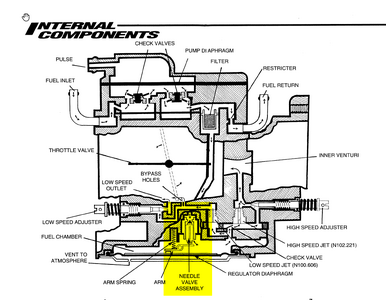

However, since the bubbles are coming from the needle, it is likely that the spring you chose is too short to hold the appropriate pressure on the arm in place or the passage itself below the needle valve has crud, or perhaps you installed the arm holding in place backwards. Here is a side blow out of a typical mikuni carb:

If the passage below has crud, you can use a kit like this or something similar to get in there and clean:

https://www.amazon.com/dp/B07Q56HGHX?psc=1&ref=ppx_yo2ov_dt_b_product_details

However, since the bubbles are coming from the needle, it is likely that the spring you chose is too short to hold the appropriate pressure on the arm in place or the passage itself below the needle valve has crud, or perhaps you installed the arm holding in place backwards. Here is a side blow out of a typical mikuni carb:

If the passage below has crud, you can use a kit like this or something similar to get in there and clean:

https://www.amazon.com/dp/B07Q56HGHX?psc=1&ref=ppx_yo2ov_dt_b_product_details

thejuice48

Active Member

You also should be using loctite 518 on the flame arrestor side. 518 is a high-temp gasket maker. It fills in the imperfections between the gasket and the metal surface. Which after years of use even in fresh water, you're bound to have imperfections on at least one mating surface.I purchased those gaskets separately off of SBT’s website. I also used a small ammount of blue locktite on the carb mounting bolts as well as the bolts on the fuel pump side or both carbs. Needle and seat was 1.5. As far as I could tell that is the correct spec as per the manual.

Although the manual only mentions 717 engines, I read elsewhere that the 951's need this as well. Besides, it helps hold everything in place while assembling.

Last edited:

I used blue loctite on the clams arrester and all blots to hold the carbs and air box together. I used three bond between the carbs and flame arrester. Loctite 518 is just gasket maker.You also should be using loctite 518 on the flame arrestor side. 518 is a high-temp gasket maker. It fills in the imperfections between the gasket and the metal surface. Which after years of use even in fresh water, you're bound to have imperfections on at least one mating surface.

Although the manual only mentions 717 engines, I read elsewhere that the 951's need this as well. Besides, it helps hold everything in place while assembling.

View attachment 62250

thejuice48

Active Member

Yes but the gasket maker you put on the gaskets between the carbs and flame arrestor to prevent air leakage. Blue or red loctite is simply a threadlocker, not a gasket maker.I used blue loctite on the clams arrester and all blots to hold the carbs and air box together. I used three bond between the carbs and flame arrester. Loctite 518 is just gasket maker.

518 is the same gasket maker you add to your reed valve areas, manifold areas, and tuned pipe with the copper gasket that attaches the two pieces. There are also some other areas.

JC-SUPERJET

Active Member

It's a Mikuni Miracle!

Are the Power Valve Blades clean and the PV Bellows in good shape?

6000 avg. rpm...Is this an SBT Engine? Youz gets wat you pay for...

Are the Power Valve Blades clean and the PV Bellows in good shape?

6000 avg. rpm...Is this an SBT Engine? Youz gets wat you pay for...

Gaskets go on dry, no sealant needed.Yes but the gasket maker you put on the gaskets between the carbs and flame arrestor to prevent air leakage. Blue or red loctite is simply a threadlocker, not a gasket maker.

518 is the same gasket maker you add to your reed valve areas, manifold areas, and tuned pipe with the copper gasket that attaches the two pieces. There are also some other areas.

518 should not be used on gaskets or on the pipe. The copper pipe ring gets Copper RTV silicone.

Nope engine was professionally rebuild by a local, reputable machenist. Power valves looked ok but I’m going to clean them. Bellows look good.It's a Mikuni Miracle!

Are the Power Valve Blades clean and the PV Bellows in good shape?

6000 avg. rpm...Is this an SBT Engine? Youz gets wat you pay for...

All gaskets went on dry. Didn’t have a gasket between the flame arrestor and the carbs so I used a small amount of three bond there only.Gaskets go on dry, no sealant needed.

518 should not be used on gaskets or on the pipe. The copper pipe ring gets Copper RTV silicone.

Similar threads

- Replies

- 29

- Views

- 750

- Replies

- 16

- Views

- 646

- Replies

- 3

- Views

- 425

- Replies

- 10

- Views

- 627