purple_people_eater

New Member

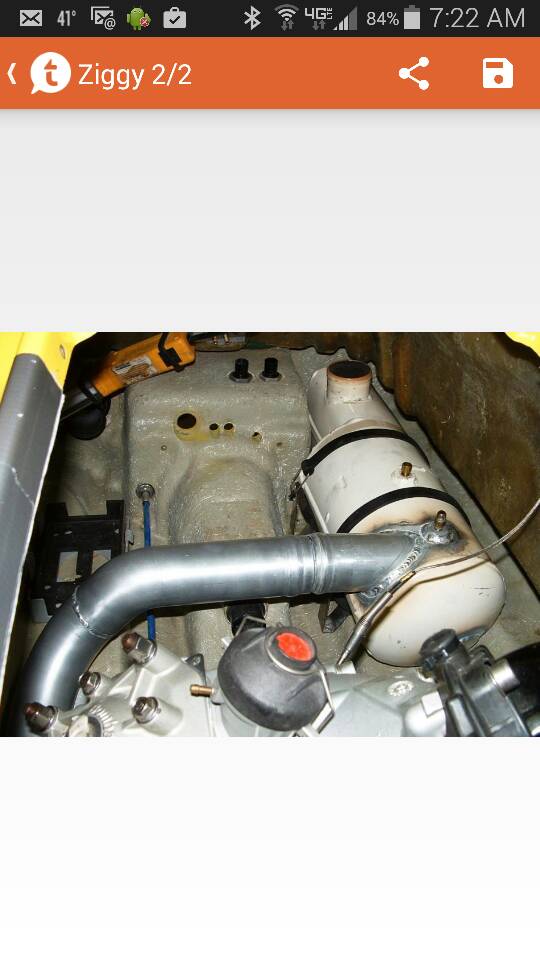

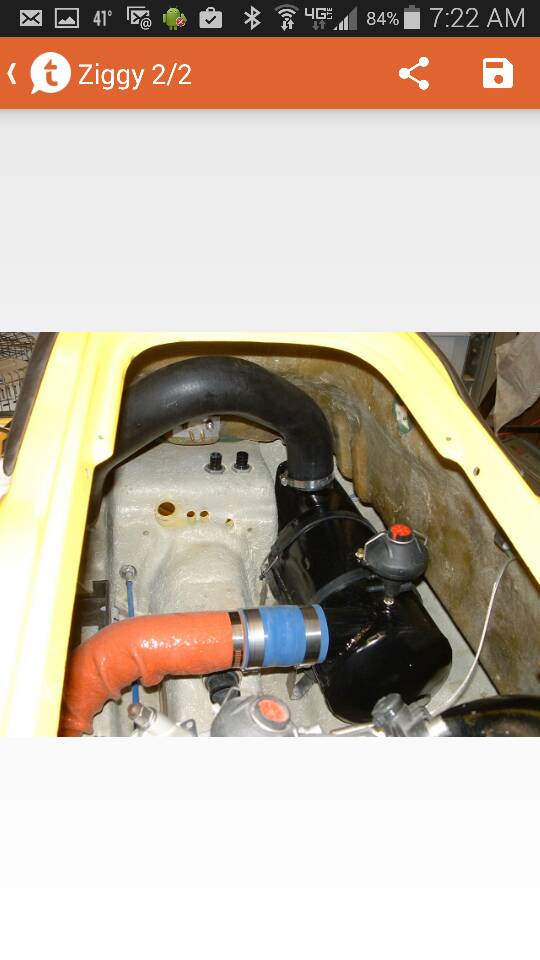

Got a little bit of an update here. I had a custom base gasket made at .086 and had the sleeves tweeked to elongate the ports a little to where they should be. I now have the motor ready to be finished, though I'm going to sandblast the head and cylinders back clean cause I got a powder coating system for Christmas

also i have changed my mind one the electronics I'm going to be using for this build. my original plan was to use a 98 single coil system of a gsx or a gtx. however after talking with some other racers they seem to swear by the 99-00 gtx 2 pick-up system and electronics system, they seem to believe that the timing curve on the 99-00 is better. so I located a 99 system and we'll see if its true.

I've also found a donor to rebuild my 00 world champ xp with and picked up an old blown Kawasaki js300 that i'm thinking about stuffing a 750 kawi into....

also picked up a 02 kawi 150 ultra to play with.,.,

also i have changed my mind one the electronics I'm going to be using for this build. my original plan was to use a 98 single coil system of a gsx or a gtx. however after talking with some other racers they seem to swear by the 99-00 gtx 2 pick-up system and electronics system, they seem to believe that the timing curve on the 99-00 is better. so I located a 99 system and we'll see if its true.

I've also found a donor to rebuild my 00 world champ xp with and picked up an old blown Kawasaki js300 that i'm thinking about stuffing a 750 kawi into....

also picked up a 02 kawi 150 ultra to play with.,.,