rjcress

Active Member

Today I gave $400 cash for a fairly nice 4 person pedal-powered paddle boat, 5 purple and black SeaDoo life jackets, a 1996 Challenger with cover, and the SeaDoo trailer that the Challenger sat on. The trailer needed new tires and tie-down straps for the 2 hour drive home, so add $185 for 2 pre-mounted trailer tires and some straps from Northern Tool. Too bad it was Sunday. Could have gotten new tires mounted a whole lot cheaper than buying pre-mounted tires. Doh!

I'll have to take my other trailer back soon to get the paddle boat, which I'll likely sell in the spring.

The guys says that the motor sucked in some water in August. He pulled the plugs and blew the water out, but had other things to do and he never got around to putting it back in the water to run and burn out any remaining water.

So the engine seized.

He lives in a Mc-Mansion on Lake Norman near Charlotte, NC. I imagine that this little old jet boat just wasn't on his priority list. His wife wanted it gone.

I bought it assuming that I'll be pulling engine and sending it off to be rebuilt... but am cautiously optimistic that I may be able to free it up. Am I dreaming?

First impressions:

- gel coat is a bit chalky on the topside, glossy on the bottom

- hardly any scratches on the bottom... looks like it was practically never beached

- some corrosion on the jet pump nozzel, but intact

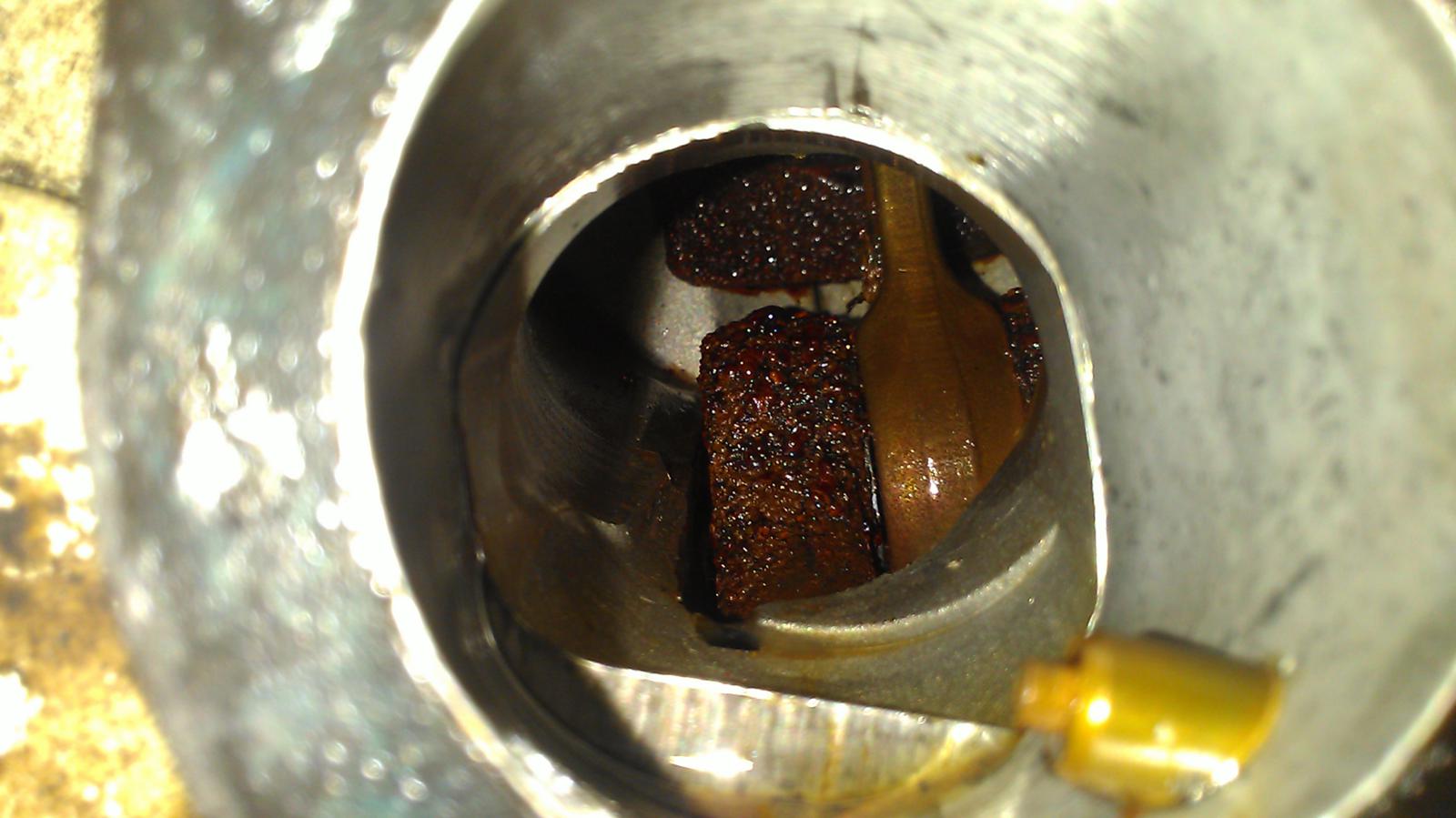

- impeller and wear ring look good looking with a flashlight from the nozzel

- main seats are unripped and serviceable, spotter seat has to be recovered

- 8 month old battery, but dead from sitting on the trailer for 3 or 4 months

- hull appears solid with no cracks, abrasions, etc.

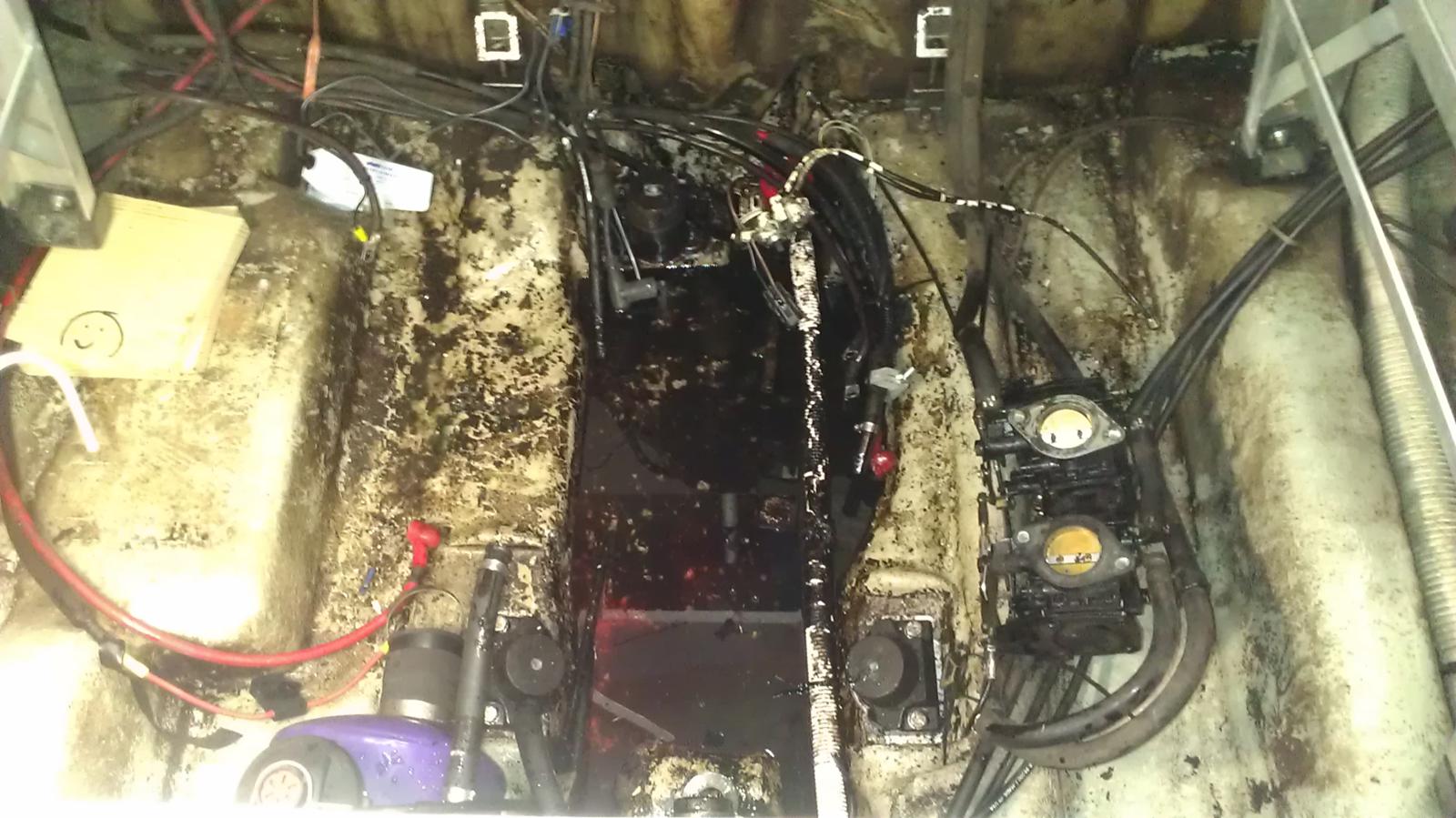

- engine bay looks pretty good. no oil, but a little dirty

- the traction pads on the swim platform are dry rotted and falling off

- the plastic hinges on both little hatches are broken

- the hideous purple and pink stickers on the sides are faded.

The only thing missing is the port cup holder that must have blown out on the drive home. I wish I would have noticed that it wasn't glued in, as I would have put it in the van.

General thoughts on how to proceed:

- charging battery so i can inventory the electrical systems to see what works/doesn't

- shot some 3 in 1 oil in the plug holes... wondering if I should have used penetrating oil... or if I'm flat out wasting my time

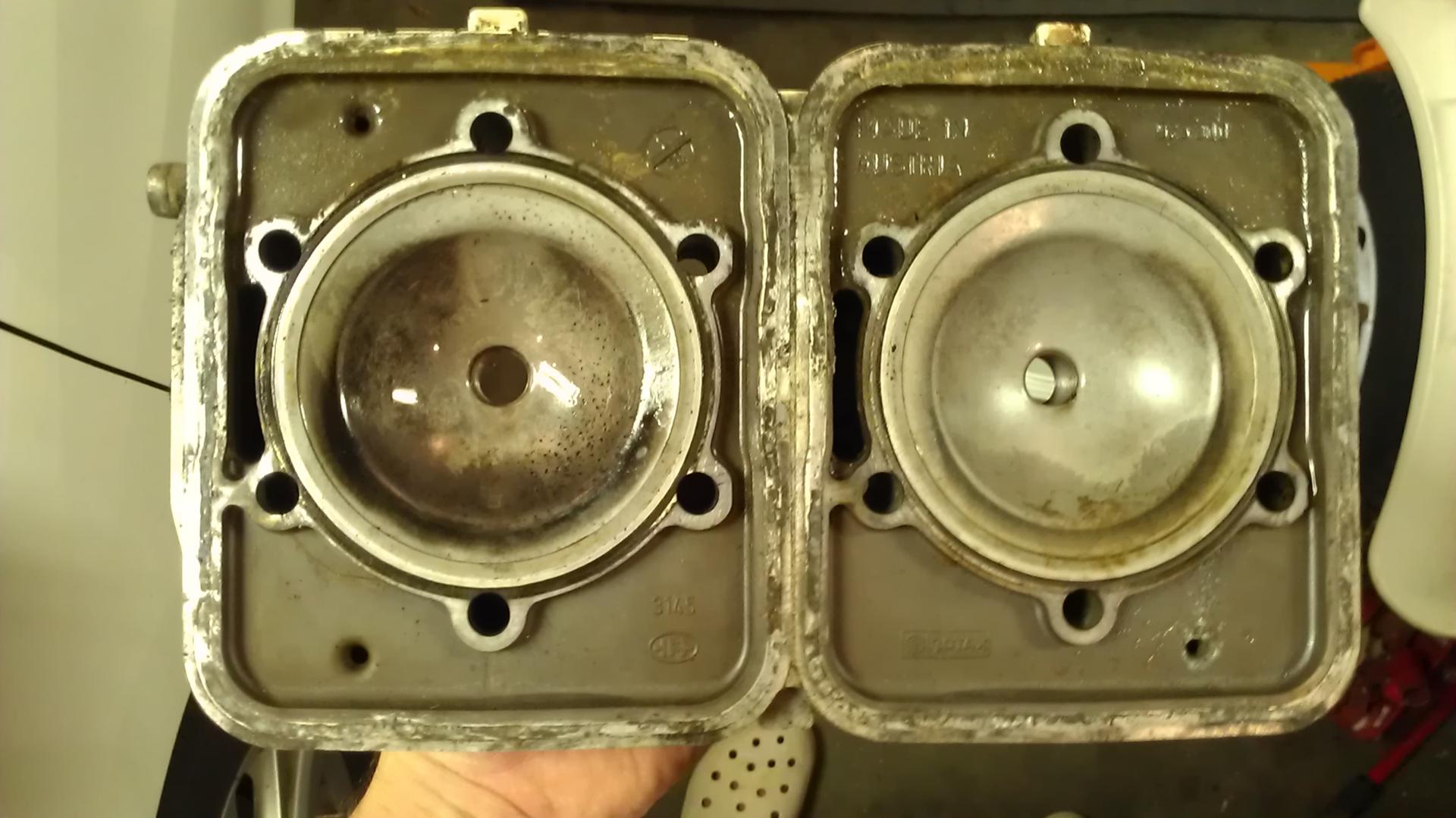

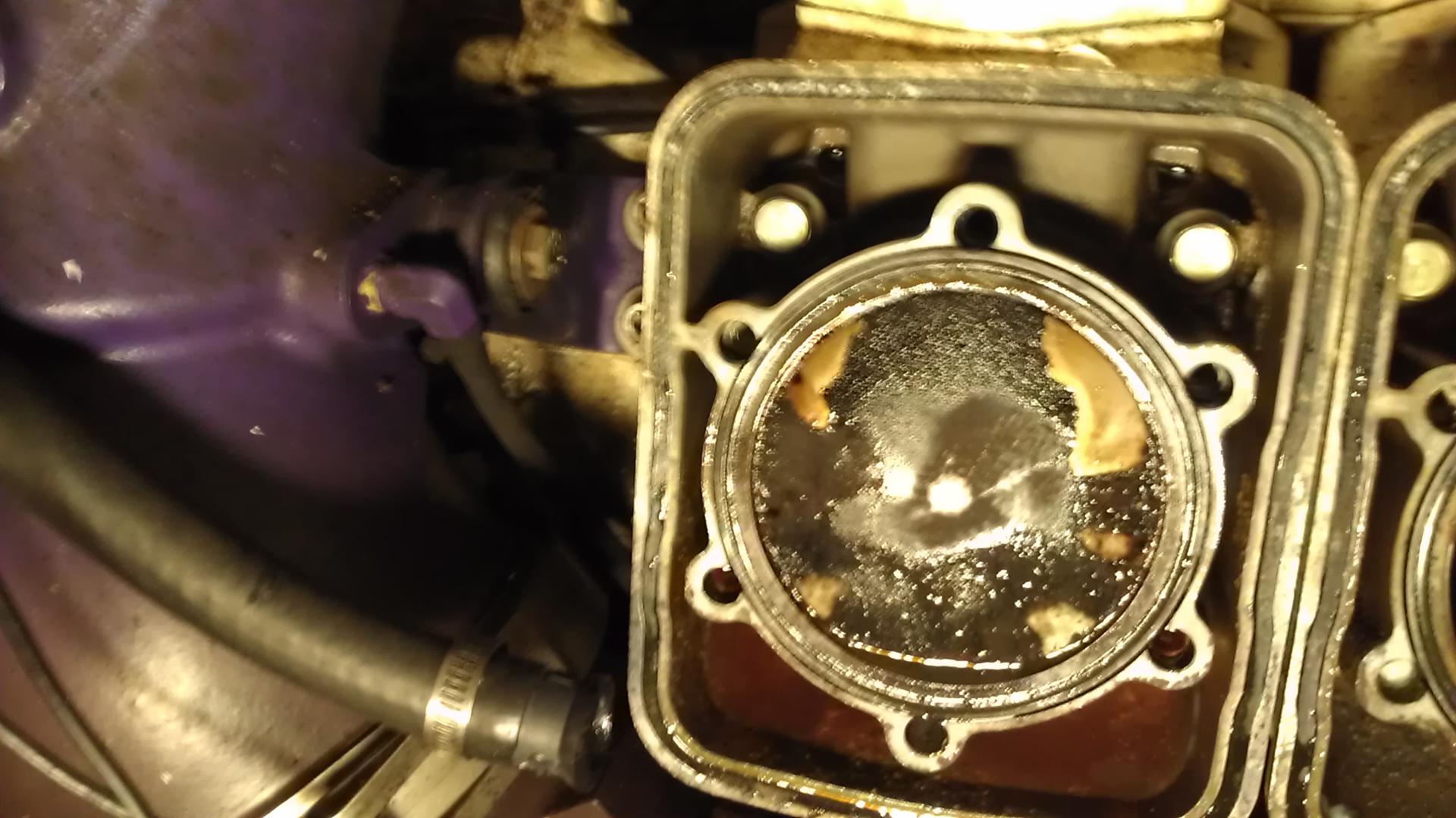

- likely to pull the head to see how bad the cylinders look

- once I've got my head around the extent of work required, then I'll decide where to start.

I'll post pics when I figure out how.

And yes, it is called Project Dog House, because my better half was totally against the purchase and is rather unhappy with me at the moment.:cuss:

I'll have to take my other trailer back soon to get the paddle boat, which I'll likely sell in the spring.

The guys says that the motor sucked in some water in August. He pulled the plugs and blew the water out, but had other things to do and he never got around to putting it back in the water to run and burn out any remaining water.

So the engine seized.

He lives in a Mc-Mansion on Lake Norman near Charlotte, NC. I imagine that this little old jet boat just wasn't on his priority list. His wife wanted it gone.

I bought it assuming that I'll be pulling engine and sending it off to be rebuilt... but am cautiously optimistic that I may be able to free it up. Am I dreaming?

First impressions:

- gel coat is a bit chalky on the topside, glossy on the bottom

- hardly any scratches on the bottom... looks like it was practically never beached

- some corrosion on the jet pump nozzel, but intact

- impeller and wear ring look good looking with a flashlight from the nozzel

- main seats are unripped and serviceable, spotter seat has to be recovered

- 8 month old battery, but dead from sitting on the trailer for 3 or 4 months

- hull appears solid with no cracks, abrasions, etc.

- engine bay looks pretty good. no oil, but a little dirty

- the traction pads on the swim platform are dry rotted and falling off

- the plastic hinges on both little hatches are broken

- the hideous purple and pink stickers on the sides are faded.

The only thing missing is the port cup holder that must have blown out on the drive home. I wish I would have noticed that it wasn't glued in, as I would have put it in the van.

General thoughts on how to proceed:

- charging battery so i can inventory the electrical systems to see what works/doesn't

- shot some 3 in 1 oil in the plug holes... wondering if I should have used penetrating oil... or if I'm flat out wasting my time

- likely to pull the head to see how bad the cylinders look

- once I've got my head around the extent of work required, then I'll decide where to start.

I'll post pics when I figure out how.

And yes, it is called Project Dog House, because my better half was totally against the purchase and is rather unhappy with me at the moment.:cuss:

Last edited by a moderator: