-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RESTO Picked up my winter project 1996 XP

- Thread starter SIMPLEARKANSAN

- Start date

- Status

- Not open for further replies.

Thanks. Yes it does shut off going both ways.

Thanks. Yes it does shut off going both ways.

That's great news !! I'd check the gauge but if the trim is working... who cares about the gauge? LOL Borrow an old gauge, hook it up and give it a try. Good Luck !!

So I cleaned the VTS gauge connection with electrical contact cleaner and blew them out. Somewhere I read that there are some kind of reeds that can go bad or just get stuck in the gauge. The person suggested lightly tapping the gauge to reset the reeds. I don’t know if it was the tapping or the cleaning but the trim gauge is working now.

The gauges are not very expensive.

https://www.ebay.com/itm/SEADOO-199...148783?hash=item2f3b1becef:g:iQoAAOSwzL9d7WGj

https://www.ebay.com/itm/SEADOO-199...148783?hash=item2f3b1becef:g:iQoAAOSwzL9d7WGj

Agreed. If it doesn’t work out I’ll definitely pick one up. Any way to text the speedometer?

Finished rebuilding the carbs. Pulled the pump to rebuild. Cleaned the gas tank and oil tank. All new fuel lines, new fuel selector,new bottom cap/filter in gas tank, new white float in pick up tube, pre-mix 40:1. Added a little premix to carbs and after four attempts it fires right up. It cranks first attempt every time. I have my primer that I still have to install and a few cosmetics to wrap it up after I finish the jet pump rebuild.

Tore into the jet pump. Has aftermarket impeller. It’s in good shape. Question is does impeller allow for more top end or provide more take off? It’s a Skat-Trak 17-22.

Got the jet pump rebuilt and everything bolted back up. Theoretically, it’s ready for a lake test. Well I hooked it up to the hose and I got issues. The big purple exhaust has a hole in the underside that the PO tried to seal with some kind of substance. I’ll scrape it off just to see what kind of hole he was dealing with. Either way I have a donor exhaust that is is pristine condition. The issue that is going to be the most time consuming is there is a leak at the base of one of my cylinders. Looks like a portion of the gasket has been torn away allowing it to leak externally. I was afraid that there could be a bigger issue with water leaking into my lower end. I pulled spark plugs, grounded wires, and turned engine over repeatedly. Luckily nothing but air pumping out. So looks like I’ll be ordering a base gasket and replacing the purple exhaust. I’d do a top end but compression was perfect.

Last pic is of extra exhaust.

I’ve never separated the exhaust. What is the secret to unhook the large band ring joining the two separate pieces of exhaust?

Just unscrew the nut and give it a few taps. Likely they Hi-Temp Copper RTV is holding it. I use a dead blow mallet.... gently. Remove the copper gasket and give it a good cleaning as well as the mating surfaces of the exhaust. Easy peasy for a man like you.

Yep, sounds like the easier fix of the two issues. Thanks

Yep compression is great. I’ll order that base gasket and try to knock it out in next couple of weeks. Got plenty of time before I really want to put it in the water. Little cold up here now.

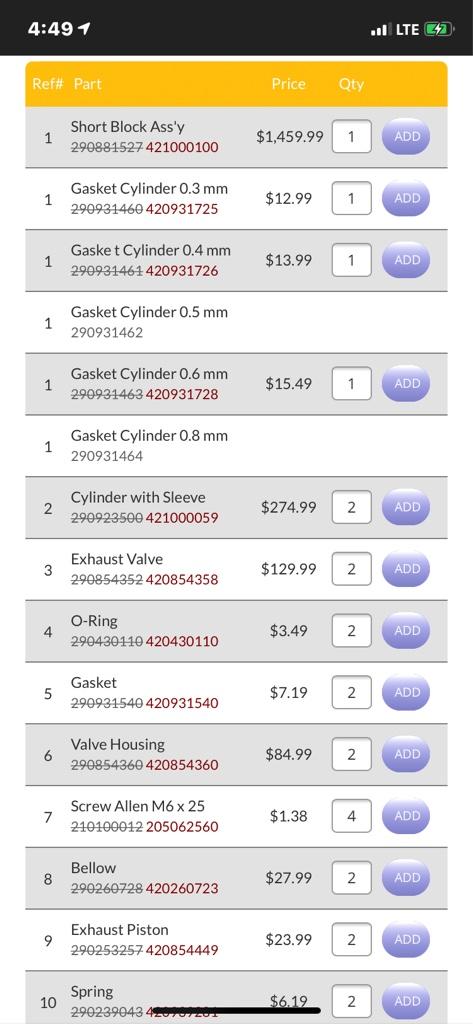

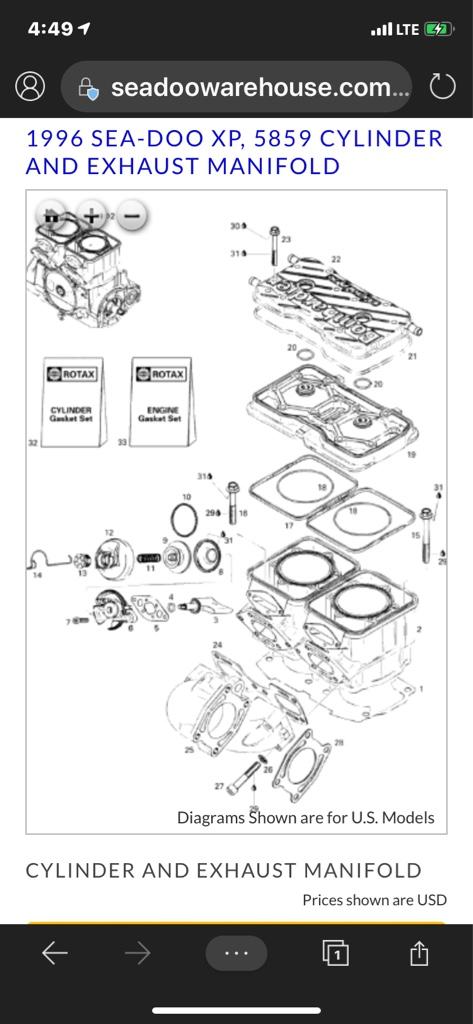

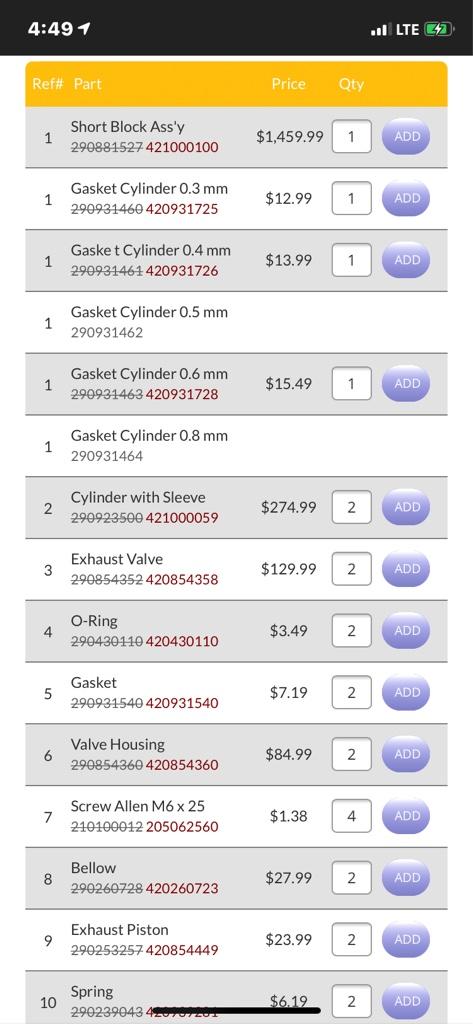

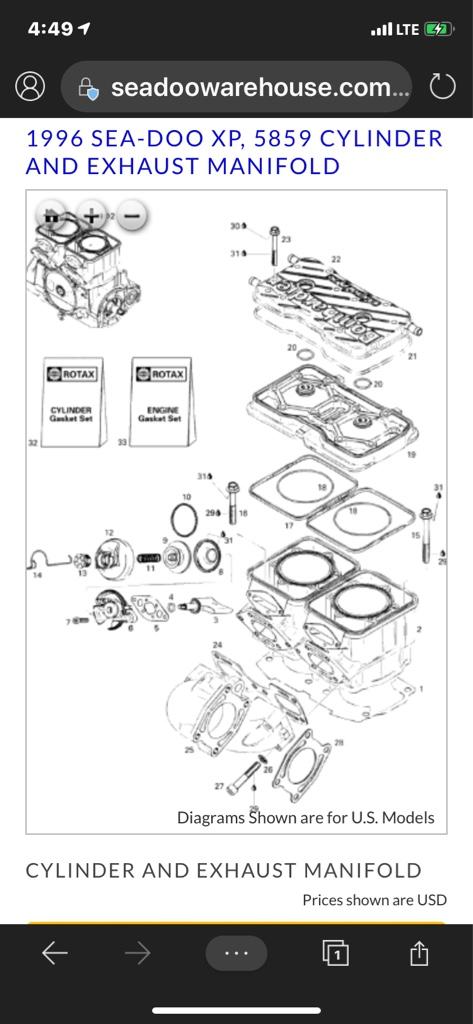

So I was looking to order a new cylinder base gasket, but there are a couple of different thickness. Which one should I order?

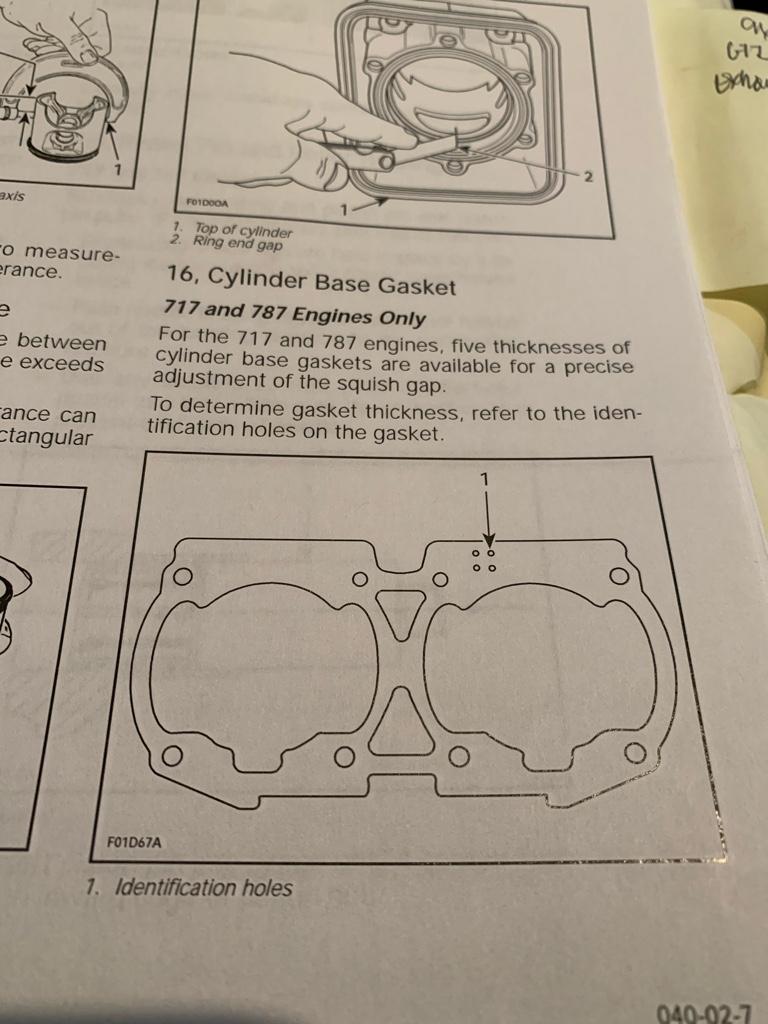

You will have to count the holes in the old gasket and order the same one. The base gasket is how the squish clearance is set and can be different on each engine so we can’t tell you which one to get.

The only other way is to measure your squish with solder as described in the factory service manual.

The only other way is to measure your squish with solder as described in the factory service manual.

Thanks for the help. I found this pic which helped me understand which holes to count. Guess I’ll remove the cylinders so I’ll know which one to buy. Do you coat the gasket with Threebond 1211?

The gasket should go on dry.

Having said that in over 25 years of building ski engines, this last summer I had a superjet that would not pass the pressure test so I had to use 1211. If there’s corrosion in the cases or cylinder gasket surfaces a very light coat of 1211 can’t hurt anything.

Having said that in over 25 years of building ski engines, this last summer I had a superjet that would not pass the pressure test so I had to use 1211. If there’s corrosion in the cases or cylinder gasket surfaces a very light coat of 1211 can’t hurt anything.

Looks like I need a 0.6 mm. The 6 holes are in a different spot that the manuals diagram, but I think it’s what I’m gonna order. I’ll try to research the brand and part number in the current gasket.

Looks like it’s a Centellen Hecker 3820. Google search doesn’t pull up this gasket.

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 994

- Replies

- 1

- Views

- 1,414

- Replies

- 2

- Views

- 441