Dang, I could have sworn I hit post yesterday, I had a big post typed up, sorry man. Here's the condensed version

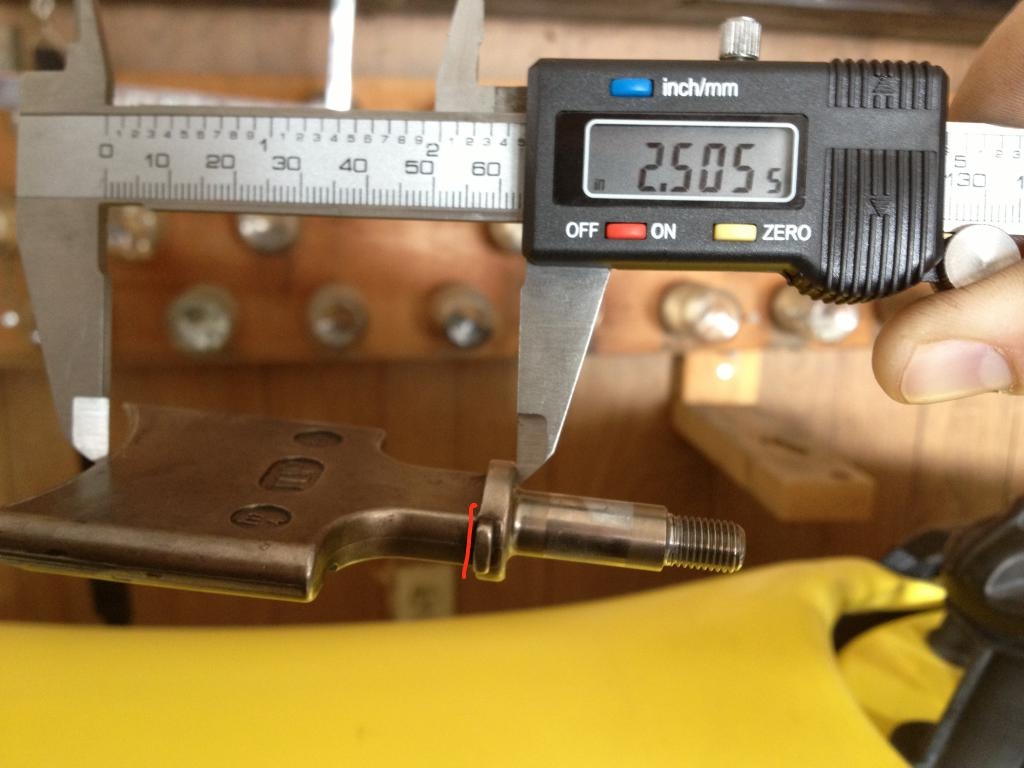

Yes the .033 is a good number, check that you have the scribe correct, it looks a bit wider than .033 by my calibrated eyes. Also, measure with the tips of you calipers not the thick of the jaw, if there are any abnormalities the thick parts will "bridge" them. Techincally you should be measuring the shaft with a micrometer not calipers, but it will get you close enough. I list the dimensions in the thread below of NEW parts. So the .392 is good, the housing is a worn like .004-.005, now add that to the other RAVE that is .390 and now your pushing .006+. As long as they are not dragging in the cylinder I guess it's OK, just lightly grease or oil the shaft before assembly. Just be sure to follow the contour of the arc.

The easy way to do it is take your bore (1.5mm oversize) which measures .059 for us PROUD Americans, now take half of that .0295 (round up) = .030. So .033 is good, no need to back measure the valve.

http://www.seadooforum.com/showthre...AVE-Guillotine&p=281220&viewfull=1#post281220

For those who can't convert from Metric

Use the convertor

http://bit.ly/WZ4AMP

Yes the .033 is a good number, check that you have the scribe correct, it looks a bit wider than .033 by my calibrated eyes. Also, measure with the tips of you calipers not the thick of the jaw, if there are any abnormalities the thick parts will "bridge" them. Techincally you should be measuring the shaft with a micrometer not calipers, but it will get you close enough. I list the dimensions in the thread below of NEW parts. So the .392 is good, the housing is a worn like .004-.005, now add that to the other RAVE that is .390 and now your pushing .006+. As long as they are not dragging in the cylinder I guess it's OK, just lightly grease or oil the shaft before assembly. Just be sure to follow the contour of the arc.

The easy way to do it is take your bore (1.5mm oversize) which measures .059 for us PROUD Americans, now take half of that .0295 (round up) = .030. So .033 is good, no need to back measure the valve.

http://www.seadooforum.com/showthre...AVE-Guillotine&p=281220&viewfull=1#post281220

For those who can't convert from Metric

Use the convertor

http://bit.ly/WZ4AMP