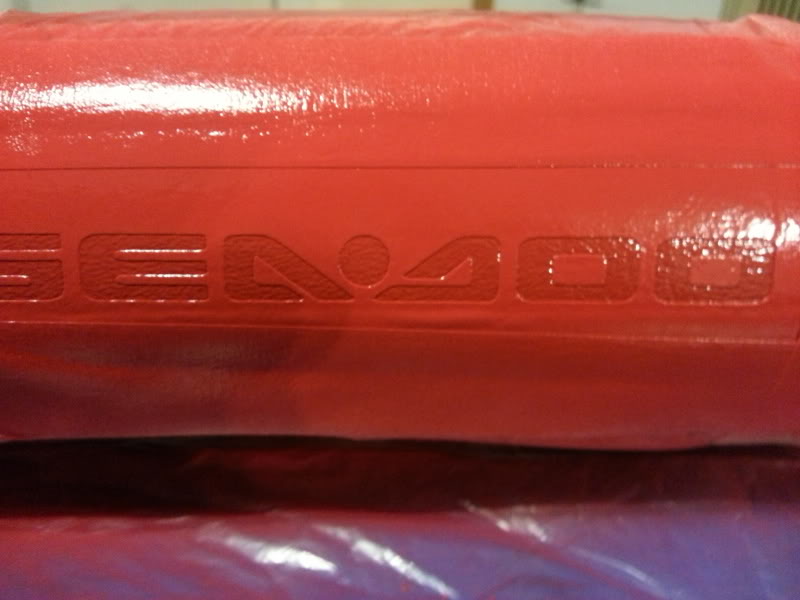

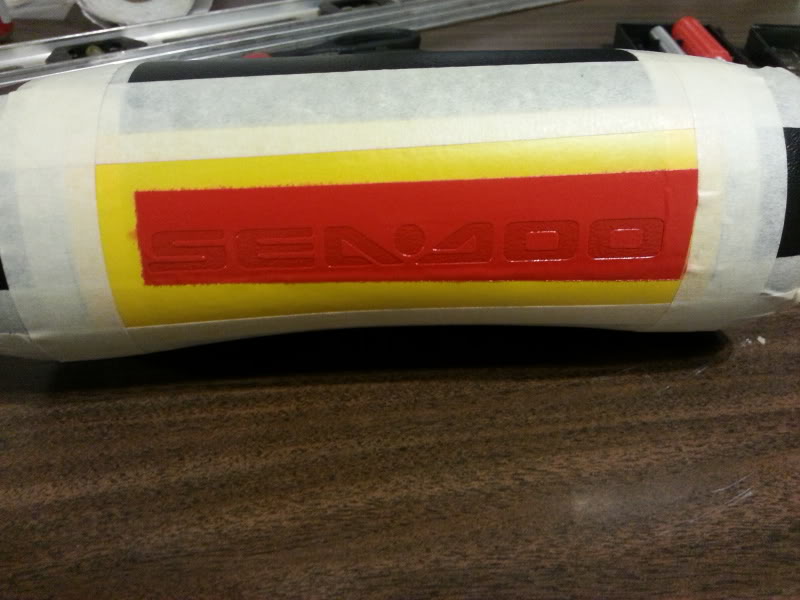

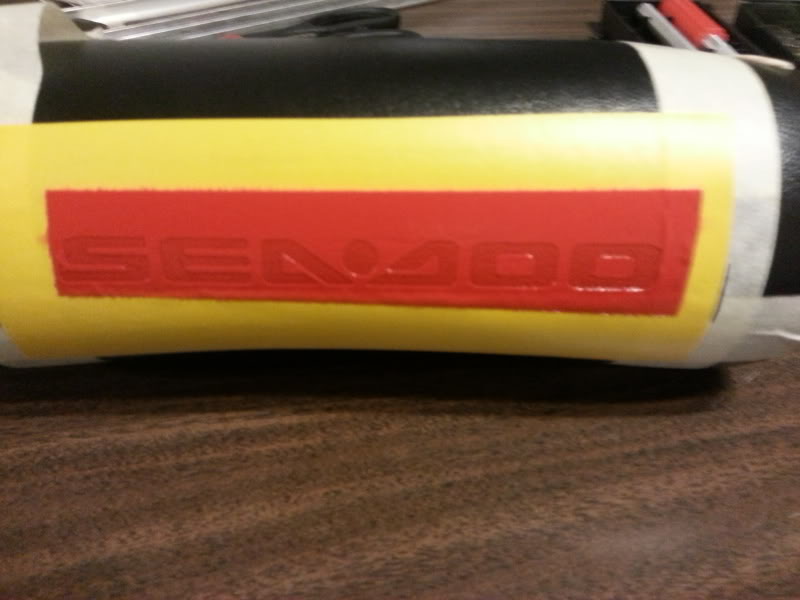

We also stenciled a seadoo logo on the handlebar pad. This time I took more pictures of the steps and even the coats of paint, so you can see how light the coats should be

To center the stencil, I measured the outside edge of the letters, the distance was 5 inches. I then measured the handlebar pad length, it was 9 1/2 inches. So I had a difference of 4 1/2 inches. Now I cut that in half which is 2 1/8 inches. So I measured 2 1/8 inches from each edge and I used tape to mark the spot. So as long as the edge of the letters are in between them it will be centered.

Now what I do to get the right height I want is this. On the stencil itself I measure 1 inch down from the letters on each end. I then will mark it and scribe a line across them. Then I use 1" masking tape and I place the top edge of the tape where I want the bottom of the stencil. Just cut on the line you make. Now just place the bottom edge of the stencil to the bottom edge of the masking tape. The stencil should now be in the perfect spot.

Peel the back mask off of the stencil

Place the stencil on your marks and make sure you put the stencil on straight and go over the stencil applying pressure to make sure the stencil adheres well.

Then pull the top mask off of the stencil

Make sure you tape off the rest of the area around the stencil. I used clear plastic and just taped it down

Now make sure to use very very light coats the first few coats just look like speckles

Coat 1

I wait 10-15 seconds per coat, I will then touch the tape around the stencil to make sure it is dry or just slightly tacky. Then I spray the next coat.

Coat 2

Coat 3

Coat 4

Coat 5

Coat 6 you can now see the stencil is almost red but the viynl still has a long way to go

Now that you see how light each coat is here is some pics a couple coats later at a time

I use about 15-20 coats

Now as soon as your last coat is done give the paint about a minute and then pull off the plastic

Then pull off the tape around your stencil

Then pull off your stencil. Start in one corner and peel it off slowly on a downward angle

Now after the main part of the stencil has been pulled off there is a few portions that were left behind inside the o's. To remove those I take the dull side of an exactoknife and gently pull up a corner. I will usually use tweezers and grab the corner that was pulled up but I forgot them today.

There was a little bleeding on this one but not enough to notice unless you get really close.

Here are some important tips.

Make sure your vinyl is clean when you start.

Make sure the room,vinyll and paint are all ate 70 degees.

Do really light coats, if you do not the paint will run and the stencil will crinkle.

Pull off the stencil before the paint completely dries or the paint may come off with the stencil. You do not have to rush, take your time pulling off the stencil. I just mean do not leave it sit a couple hours before you peel it off.

Make sure to shake the can between coats.

It looks like I just posted a mini how to in the middle of this thread.