Jetskigoodies

Well-Known Member

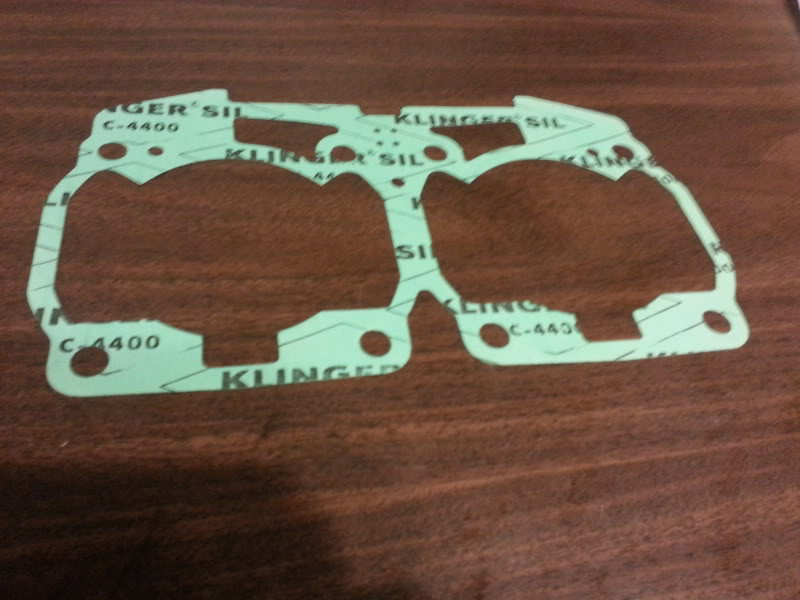

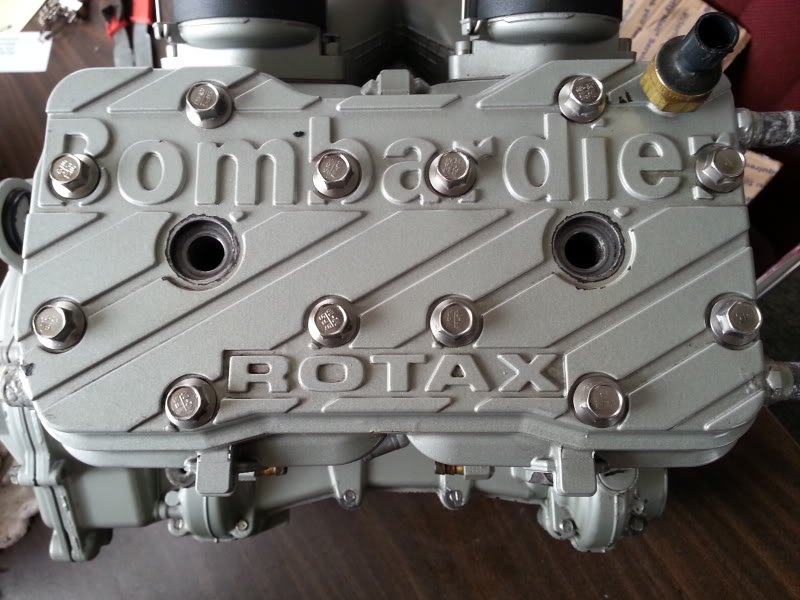

1 of the rave valves before and after

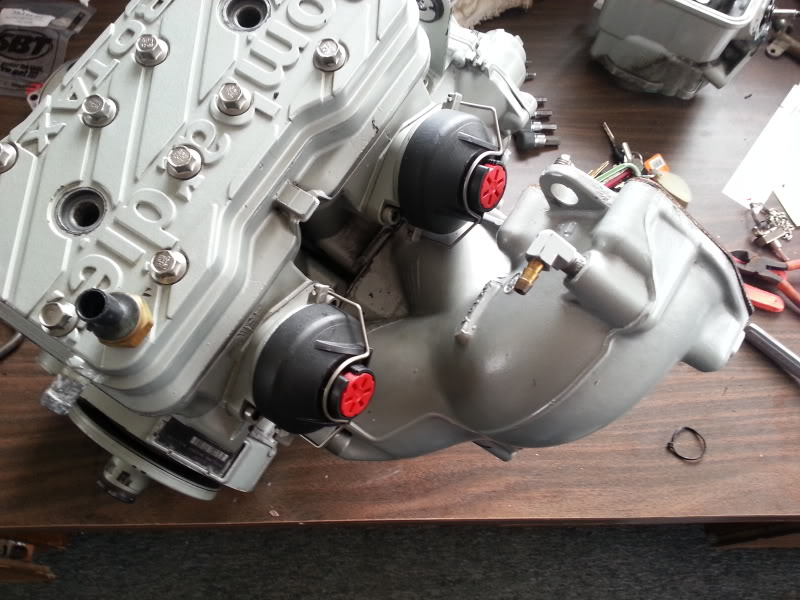

Ok, now I feel stupid and won't tell you how I replaced the one on my GSX....