Well, it's official: I'm horrible at keeping build threads up to date. I've been super busy around here and have neglected this thread, but it's time to fix that!

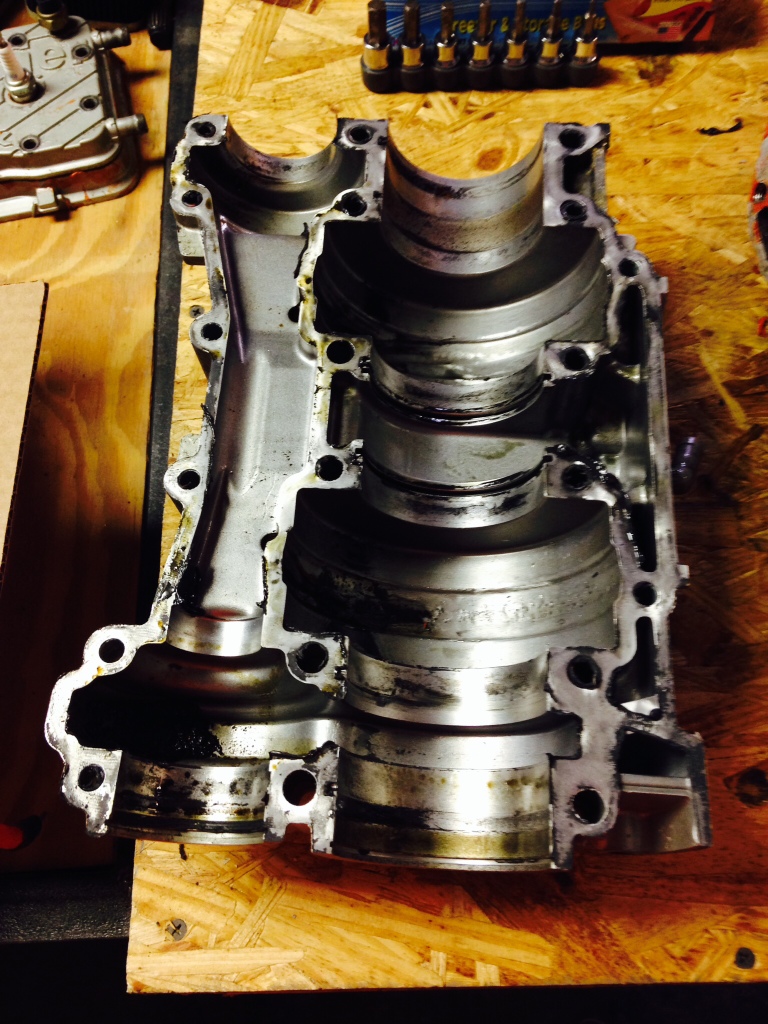

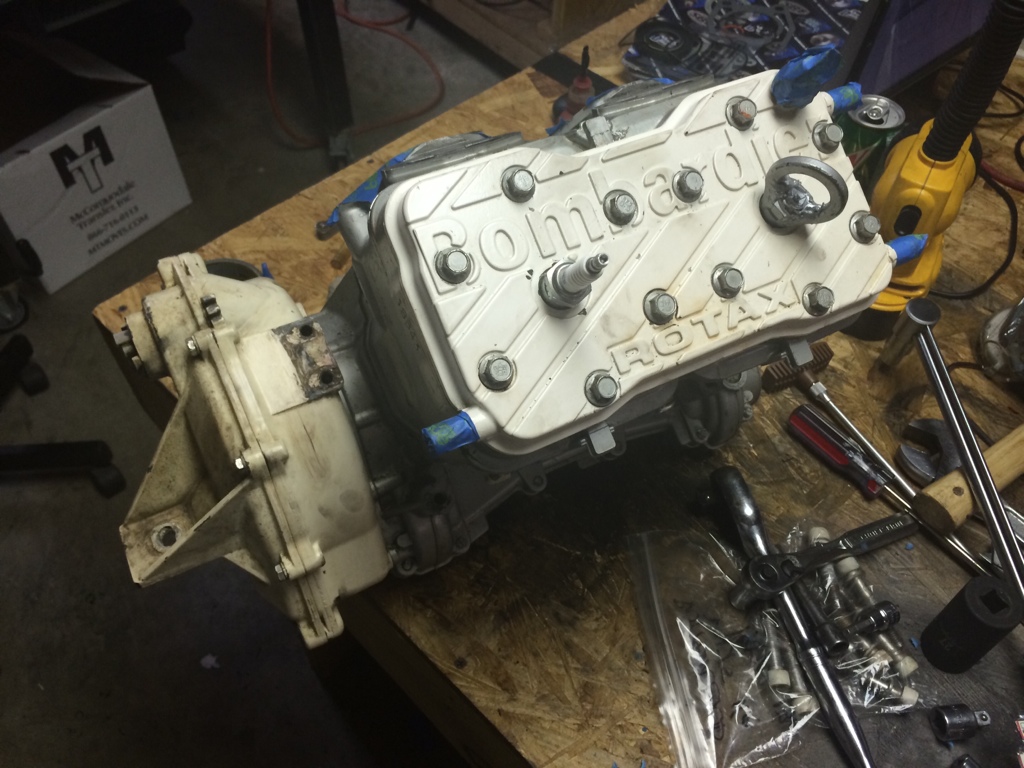

So to recap where I left off: the motor was disassembled, cleaned and inspected, reassembled, painted and is now sitting in the ski. The exhaust was painted and is also bolted in at this point. All the fuel lines have been replaced as well as the fuel baffle being repaired. With a week to go I still needed an MPEM, carbs cleaned, pump oil changed, pump installed… yeah. I had a long way to go!

Now to continue. With the motor aligned and locked down, I turned to hooking up the linkages and hoses which went smoothly. Now is when I have to give props to Minnetonka4me (again). Great all around guy to deal with and has super fast shipping! Once I got the new MPEM in hand, it was installed and all the electrical was plugged in and buttoned up. After picking up a new battery, it was time to light the 787 off for the first time. This is where #111 really tested my patience. The first issue began when it wasn't getting any spark. Since this was the rear E box from #2, my initial thought was a bad coil. After checking it out, it seemed fine. To see if I had an issue further up, I swapped the coil on the GTX over since I knew it was good. Nothing. At this point, I was turning to an issue further up the electrical system, all of which checked out fine at the time. Why I didn’t think to check earlier is beyond me, but I went back and looked at the wiring to the coil thinking I had a bad connection. It had a power wire, but no ground. Odd. That couldn't be right. So after grounding the coil, the craziest thing happened. It had spark! Whoda thunk? With that senior moment out of the way, it was time to FINALLY hear the 787 run. Or so I thought.

Issue #2 was that it didn’t want to draw fuel- it would run long enough to empty the fuel filter, but wouldn't siphon any more fuel. After cleaning the fuel selector valve (again), the problem still persisted. I know, I should have ordered a new selector before now, but that simply wasn't an option at this moment. After bypassing it and refilling the fuel filter bowl, it was time to try again. I hit the start button and after a few turns, it fired up and ran like a champ. To say I was excited would be an understatement. I was going to get to ride this thing after all.

With the ski running, it was time to finish reassembly. I painted the nozzle and installed the pump after checking it out and replacing the pump oil. The wear ring looked new, as did the pump oil. Now it was time to finish the handle bars, where I had left off last time.

Before I went to hacking away any more at the throttle mount, I decided to do a test assembly. To my surprise, it fit great. I could have done a little relief trimming, but that was a detail I could save for later. Next was to figure out hot to mount the handlebar pad, since I didn't see the GSX stem swapping over to the XP. The solution was a simple square bracket with 4 holes in it that was drawn from the GSX stem. After a little massaging, this was the final result:

After finishing up the trailer and packing enough spare parts to fix about anything, I put the skis on the trailer late Thursday night in order to leave Friday after work.

Enter Friday afternoon.

After quite literally outrunning a rain storm to the lake, I threw on a life jacket and backed the trailer off in the water to try and squeeze any riding time I could before the storm got me. After pushing off from the beach, I hit the start button and the ski fired right off. After idling around for a while to make sure everything was ready to rip, I slowly got more confidence in the ski. I'm quite sure that there was a permanent grin on my face for the whole hour I was out and I did my best to not hammer down on the ski, but for those of you who have ridden an X4 you know that's hard. REAL hard. With what throttle I was willing to give it considering it was a fresh top end, I could already tell this thing was an animal. With the rain coming down the river, I slipped the GTX and XP in the boat house and put them up for the night.

Over the next 2 days the ski did great, save for a random fuel delivery issue that needs to be sorted out. The acceleration and handling of this ski is nothing short of insane. I now understand the obsession you guys have with these skis! My crew ventured out to the rope swing at one point:

Eventually the DESS post and choke will be moved up top, but that is a project for another time. Overall, I am more than pleased with how this turned out and I see this X4 being in the stable for quite some time. I have been catching up on some other projects, so due to time and money, #2 will be put on the backburner until Christmas or so. I plan to put a parts list together for it very soon and start collecting parts. Hope y'all have enjoyed the first half of the build. There is still another X4 in my shop waiting to be brought back from the dead. Stay tuned!