Hi

Having problems with supercharge rebuild (2015 GTX 260hp)

I have followed all the instruction but the new shaft feels very tight to spin it by hand

I have got up to step 13 on SBT instruction, I have put the new bearing in the housing

then put the bearing on the shaft

Put the thrush washer and space on the shaft

inserted the shaft and bearing into the housing

then put the step collar and o ring and then install the impeller and notice that the shaft was tight to turn

it sounds like it is binding on something I think it could be the step collar.

I notices that the step collar is turning with the shaft, is this normal

Can I remove the retaining disk while the shaft is still install in the body to try and find out what is causing the binding

I am using a brand new kit

the bearing went on the shaft and in the housing ok

I have not started to put the gear or washer etc on yet so I could take the shaft out if needed

I did notice that the oil seal in the new retaining collar sits higher than the oil seal in the old retaining collar

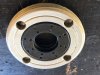

I bought this jet ski at an auction the ski was a repo. the housing has some damage but should not effect it unless it has bent the housing some how, it looks like a bearing has gone (see pics)

The guy must have started to put a new S/C kit in the S/C as the bearings and shaft that I took out of the S/C looked new

I just need to find out why the shaft is tight to turn and what it is binding on

Thanks

Having problems with supercharge rebuild (2015 GTX 260hp)

I have followed all the instruction but the new shaft feels very tight to spin it by hand

I have got up to step 13 on SBT instruction, I have put the new bearing in the housing

then put the bearing on the shaft

Put the thrush washer and space on the shaft

inserted the shaft and bearing into the housing

then put the step collar and o ring and then install the impeller and notice that the shaft was tight to turn

it sounds like it is binding on something I think it could be the step collar.

I notices that the step collar is turning with the shaft, is this normal

Can I remove the retaining disk while the shaft is still install in the body to try and find out what is causing the binding

I am using a brand new kit

the bearing went on the shaft and in the housing ok

I have not started to put the gear or washer etc on yet so I could take the shaft out if needed

I did notice that the oil seal in the new retaining collar sits higher than the oil seal in the old retaining collar

I bought this jet ski at an auction the ski was a repo. the housing has some damage but should not effect it unless it has bent the housing some how, it looks like a bearing has gone (see pics)

The guy must have started to put a new S/C kit in the S/C as the bearings and shaft that I took out of the S/C looked new

I just need to find out why the shaft is tight to turn and what it is binding on

Thanks