Last week on Wednesday we bought a 96 xp, it had 150 compression in each cylinder but weak spark, the rear ebox screw that holds the grounds in was stripped and barely held in.

On Thursday we bought a 96 gtx with a blown motor, upon inspection the rear cylinder blew, the rear carb filter was completely filled with grean goo from the grey fuel lines. At one point it had a sbt swap, with a brand new oem oil pump. The fuel delivery was never fixed so the sbt motor leaned out.

This gtx was very clean. It has a new seadoo cover and a new skat trak slim line impeller. We ended up taking the good motor from the xp and putting it in the gtx.

Here is the impeller, we had to take that out of the pump it was in. The pump was broken, well one of the nuts where the nozzle bolts too was snapped.

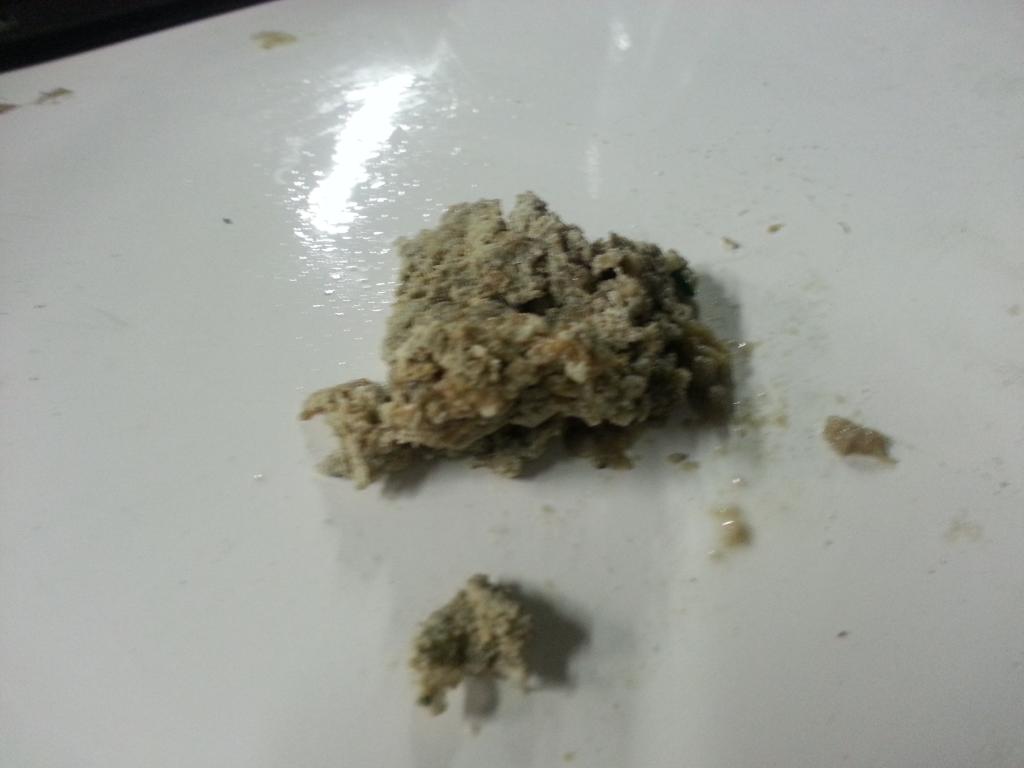

We pulled off the oem mat and there was an adheisive. We ended up scraping it off.

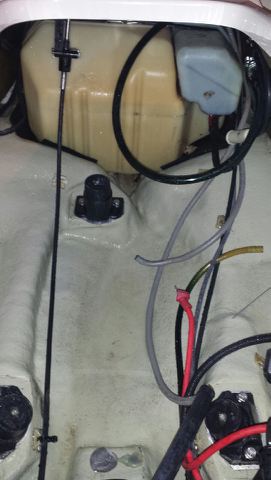

The inside was cleaned

We replaced all the fuel lines, put new oil in the pump we put on, and washed it.

Sunday we took her to the lake

Started up fine ran good for 5 minutes then it would only get to 3500 rpms and she acted like it was hitting the rev limiter. Rj shut if off and turned it back on and she ran fine for a few minutes then same symptoms. We pulled the red wire on the rectifier and she ran great for the rest of the day.

Hit 7000 rpms and was quite responsive, for as big as it is she seemed pretty fast and it cut through the chop nicely.

Rj was doing 360's on it and it ripped the reverse bucket off.

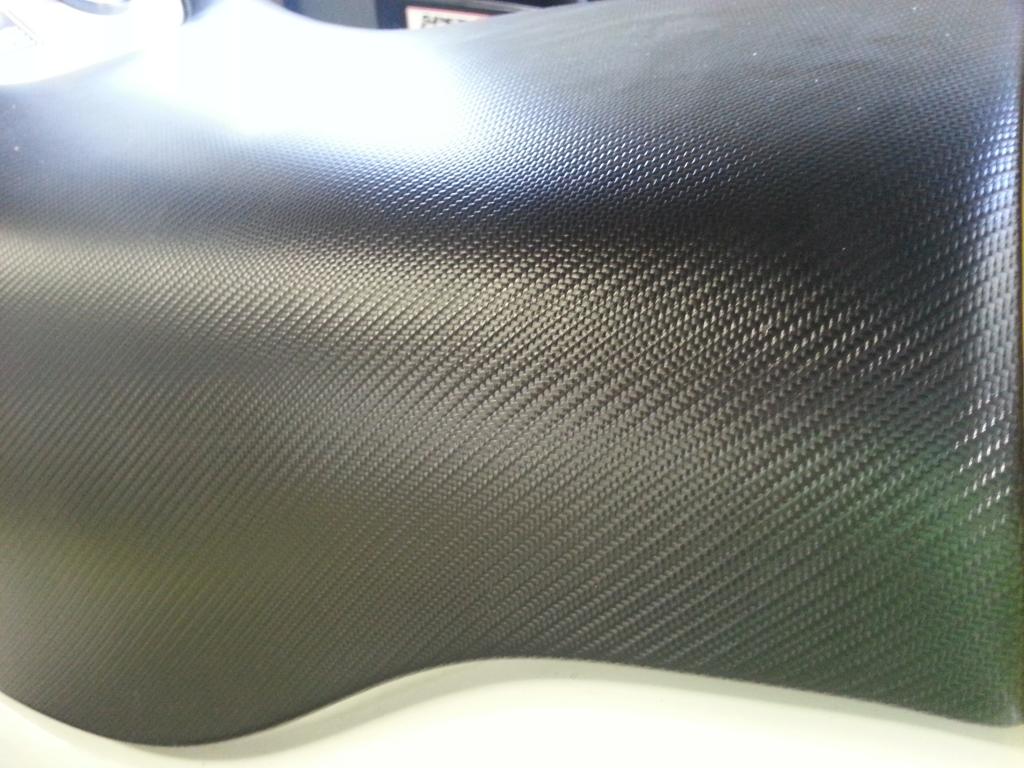

So all that is left for this is installing the new hydroturf we ordered from pwc muscle, buffing it, new rectifier and reverse gate.

The info gauge has the burnt lcd and the seat has a small tear.