-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hull Repair on my 96XP

- Thread starter Krispy

- Start date

- Status

- Not open for further replies.

jammin777

Well-Known Member

yep i applied the first coat as a mist waited 2 min the applied the rest one right after the other. no curing between coats. i would recommend 10 to 20% duratech on the first coats because of better flow with less orange peel and possibly better cure. mine came out a rock solid Finnish. it does not lower the integrity of the gel.

Krispy

Well-Known Member

Out of curiosity, how much material did you buy? Quart, Gallon etc.... just for reference

1 gallon of neutral gelcoat

5 oz neutral pigment

1quart of duratec clear

1 pint of styrene (thinner)

An appropriate amount of MEKP to catalyze the duratec and gelcoat

A small amount of wax, I forget the exact proportions

And a mil thickness gauge

Total was $116 to my door.

It should be more than enough to do the job but we will see...

Sent from my iPhone using Tapatalk

Krispy

Well-Known Member

A quick update: over the weekend I was able to transport the Hull to my neighbors spray booth. The plan was to spray the new gelcoat on last night but the weather has turned cool. I have been advised not to apply the gelcoat if the surface and material temperatures are not above 72f.

We did get it masked off however.

Now we are waiting for some warm days.

This weekend looks pretty good.

Sent from my iPhone using Tapatalk

We did get it masked off however.

Now we are waiting for some warm days.

This weekend looks pretty good.

Sent from my iPhone using Tapatalk

Cool Project! Looking forward to hearing about the gel coat. Funny how a small job turns into a full-on resto. I was going to go with black on the bottom as well... I guess engineers all think alike. In the spirit of not cramping your style, I'll do something else.

Couple of questions:

What made you decide to go with US Composites instead of GelCote Intl?

What did you come up with to get the exhaust thru-hull fitting out? I was thinking about sacrificing one of my cheap Irwin woodworking clamps - it would need to be cut to get it in there, but I'm not sure it would work. Might be best to fabricate a tool.

Couple of questions:

What made you decide to go with US Composites instead of GelCote Intl?

What did you come up with to get the exhaust thru-hull fitting out? I was thinking about sacrificing one of my cheap Irwin woodworking clamps - it would need to be cut to get it in there, but I'm not sure it would work. Might be best to fabricate a tool.

In the following thread I made a removal tool for the through hull fitting. There is also another one that Tonka's dad made up, you should be able to get an idea.

http://www.seadooforum.com/showthre...ll-exhaust-outlet-removal&p=388074#post388074

Sent from my SGH-T889 using Tapatalk 2

http://www.seadooforum.com/showthre...ll-exhaust-outlet-removal&p=388074#post388074

Sent from my SGH-T889 using Tapatalk 2

Krispy

Well-Known Member

Cool Project! Looking forward to hearing about the gel coat. Funny how a small job turns into a full-on resto. I was going to go with black on the bottom as well... I guess engineers all think alike. In the spirit of not cramping your style, I'll do something else.

Couple of questions:

What made you decide to go with US Composites instead of GelCote Intl?

What did you come up with to get the exhaust thru-hull fitting out? I was thinking about sacrificing one of my cheap Irwin woodworking clamps - it would need to be cut to get it in there, but I'm not sure it would work. Might be best to fabricate a tool.

I ended up making a tool a bit simpler than racer or Tonka or the others, but I used theirs for inspiration

http://www.seadooforum.com/showthread.php?68903-Through-hull-exhaust-outlet-removal

As far as using US composites, at first it was to stay within budget. I was considering that I needed to match my OEM color, but then after seeing how hard it would be to get the color spot on for all the repair areas I wanted to do I figured I would just do a color change. I shopped around for quite a bit and found US composites to be the best in price. Also, I was able to speak with their "tech" guy several times to determine that I had chosen the best materials (and application methods) for the job. Lets hope he/we were right!

As far as yellow top and black bottom, I am cramping Seadoo's style! The 99 SPX was my inspiration for my color choice, and black is a pretty hard color to mess up if you have nothing to compare it with. Also, being black I should be able to get the color change with minimal (relatively) thickness.

We will see how it all plays out, Steve at USC is a bit anal about how things should be applied so I am still waiting for warmer weather to spray.

Krispy

Well-Known Member

Turning that 96 xp into a 99spx!!! I'm loving it, it's looking good

Thanks fellas, just finished up the final coat. There is still some texture in the gelcoat but it isn't terrible.

I will have a few nights of wet sanding ahead. No worries.

I am going to let it cure for about 36 hours and then pick it up and put back in my garage for sanding and reassembly.

This guy is ready to get back in its home!

Sent from my iPhone using Tapatalk

Jetskigoodies

Well-Known Member

Now you just need a hump seat, and a set of 99spx replica decals from pwcgraphics.com

Krispy

Well-Known Member

Now you just need a hump seat, and a set of 99spx replica decals from pwcgraphics.com

Yes, that thought crossed my mind as I was painting the engine. I really was just picking color schemes that I like and that would complement the seat cover I have etc.

And then it dawned upon me, I am pretty much making a 99 spx....

I don't know how I feel about that really. I am a Corvette guy, I own a Z06 Corvette, every time I see a standard Corvette with Z06 wheels/ brake ducts etc. I think "woah" you shouldn't be doing that, "that isn't really a Z06" I feel like if I clone the SPX I am just as bad.

Now if [MENTION=70010]RatFink[/MENTION] wants to hook me up with a special price on his SPX clone decals then I may have to make my ski a clone just to show off his handy work!

Krispy

Well-Known Member

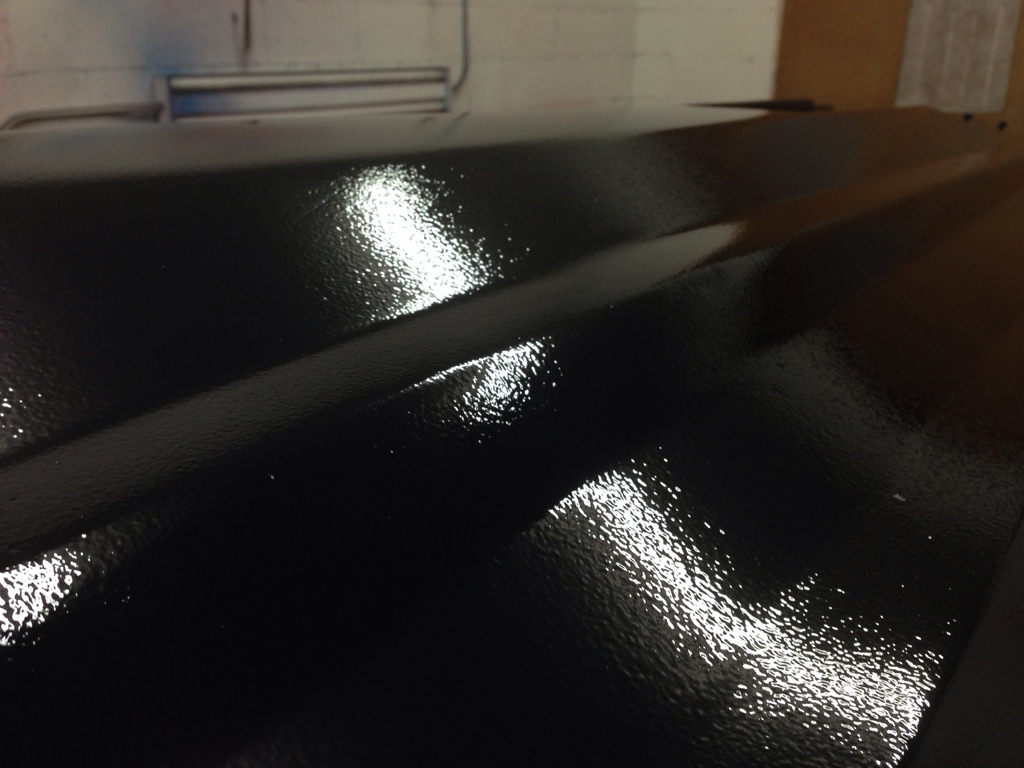

Well, small update. I got the hull back into my shop last night after plenty of time curing in the paint booth.

Now starts the wetland process!

Still working on 600, but here are some poser shots while wet.

This wet sanding is going to be a long process.

Sent from my iPhone using Tapatalk

Now starts the wetland process!

Still working on 600, but here are some poser shots while wet.

This wet sanding is going to be a long process.

Sent from my iPhone using Tapatalk

Front Bumper Rivets:

You will have 46 left over, but I F'd up a few cause my rivet gun got jacked up and now I only have like 15 left. Yes, I burned through a bunch, but the HX side sponsons deals take a bunch of the same ones, and I hand them on and off at least twice. Remember to push in real hard so all the rub rail is tight to the deck before you squeeze the gun.

http://www.mcmaster.com/#97447a072/=rfc0uh

Rub rail rivets

http://www.mcmaster.com/#97447a065/=rfc1fn

Side intake Doo-dads (black plastic scoops at the front of the seat)

http://www.mcmaster.com/#97447a145/=rfc34m

Hardware store you can only get up to a 1/2" in grip length, but if you lean on it they will work just fine.

These might be a tad too long but should work. Hardware store is probably like $4 for 15, Mcmaster is $9.92 for 250. You can see why I go to McMaster. The shipping is like dirt cheap too. I just bought 20, M8 helicoil inserts and they shipped for less than $5 and I had them the same day.

Hull is looking good. I was nervous when I saw all the peel, I said to myself his arms are gonna be puckered out. If that last pic is wet sanded and buffed it's looking real good.

You will have 46 left over, but I F'd up a few cause my rivet gun got jacked up and now I only have like 15 left. Yes, I burned through a bunch, but the HX side sponsons deals take a bunch of the same ones, and I hand them on and off at least twice. Remember to push in real hard so all the rub rail is tight to the deck before you squeeze the gun.

http://www.mcmaster.com/#97447a072/=rfc0uh

Rub rail rivets

http://www.mcmaster.com/#97447a065/=rfc1fn

Side intake Doo-dads (black plastic scoops at the front of the seat)

http://www.mcmaster.com/#97447a145/=rfc34m

Hardware store you can only get up to a 1/2" in grip length, but if you lean on it they will work just fine.

These might be a tad too long but should work. Hardware store is probably like $4 for 15, Mcmaster is $9.92 for 250. You can see why I go to McMaster. The shipping is like dirt cheap too. I just bought 20, M8 helicoil inserts and they shipped for less than $5 and I had them the same day.

Hull is looking good. I was nervous when I saw all the peel, I said to myself his arms are gonna be puckered out. If that last pic is wet sanded and buffed it's looking real good.

PWC_Graphics

Member

Now if @RatFink wants to hook me up with a special price on his SPX clone decals then I may have to make my ski a clone just to show off his handy work!

Send me an email - I'll see what I can do: info@pwcgraphics.com

Krispy

Well-Known Member

Krispy

Well-Known Member

Quick update:

Still wet sanding, still in my most aggressive grit (600). I have uncovered a few small voids in the gelcoat, and I sanded through a small portion of the black gelcoat on a radius. So once I get it all sanded in 600 I will have to do some patching.

Here is how it sits as of last night...

Sent from my iPhone using Tapatalk

Still wet sanding, still in my most aggressive grit (600). I have uncovered a few small voids in the gelcoat, and I sanded through a small portion of the black gelcoat on a radius. So once I get it all sanded in 600 I will have to do some patching.

Here is how it sits as of last night...

Sent from my iPhone using Tapatalk

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 459

- Replies

- 2

- Views

- 565

- Replies

- 8

- Views

- 843