SeaDooGood

New Member

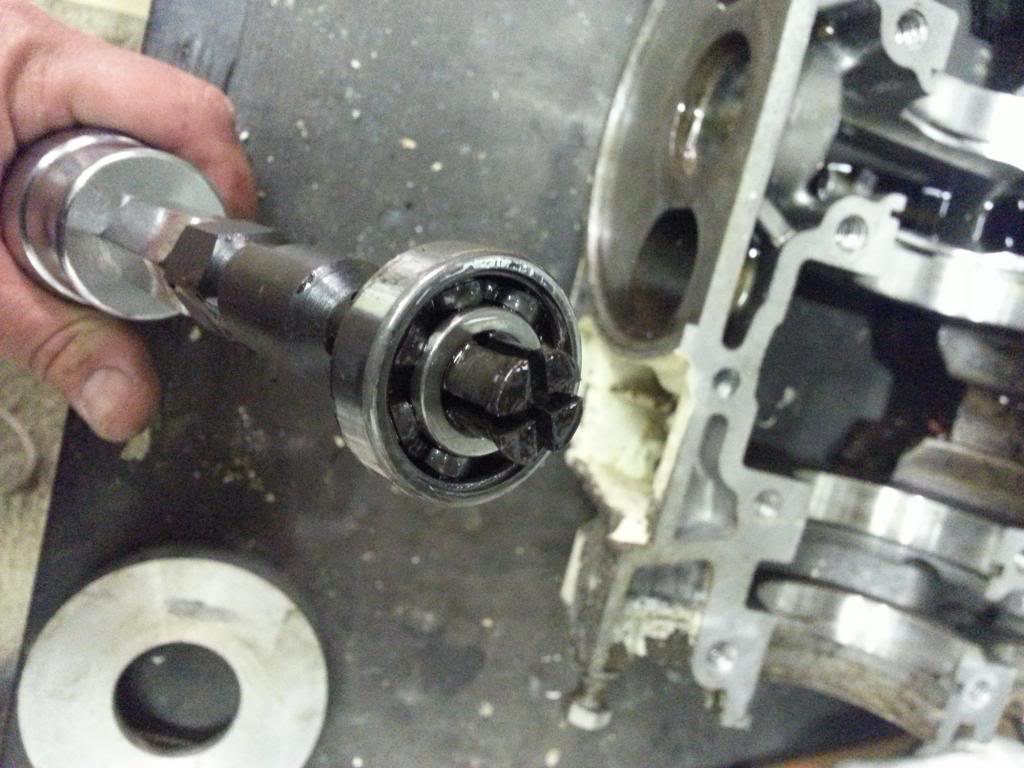

Removed the pump cone today to inspect and change oil and THIS is what I find it looking like inside! It was COMPLETELY dried up! First and second pics shows what the pump cone looked like inside and in the second pic it shows what I pried out, some little object that was stuck and hardened in there (I'm assuming it was part of the inside of the cone). The impeller moves pretty freely, but I pulled the little rubber off the end and it broke off (4th pic). My question is now....WHERE DO I GO FROM HERE!? I'm kinda freaked out, but hopefully I can fix this with minimal cost. What do I need to replace...drive shaft, pump cone, who jet pump assembly? I'm lost right now. The jet pump assembly all seems good, so could I just get a new pump cone? What about the drive shaft? PLEASE HELP...thanks!

Attachments

Last edited by a moderator: