glsmohio

Well-Known Member

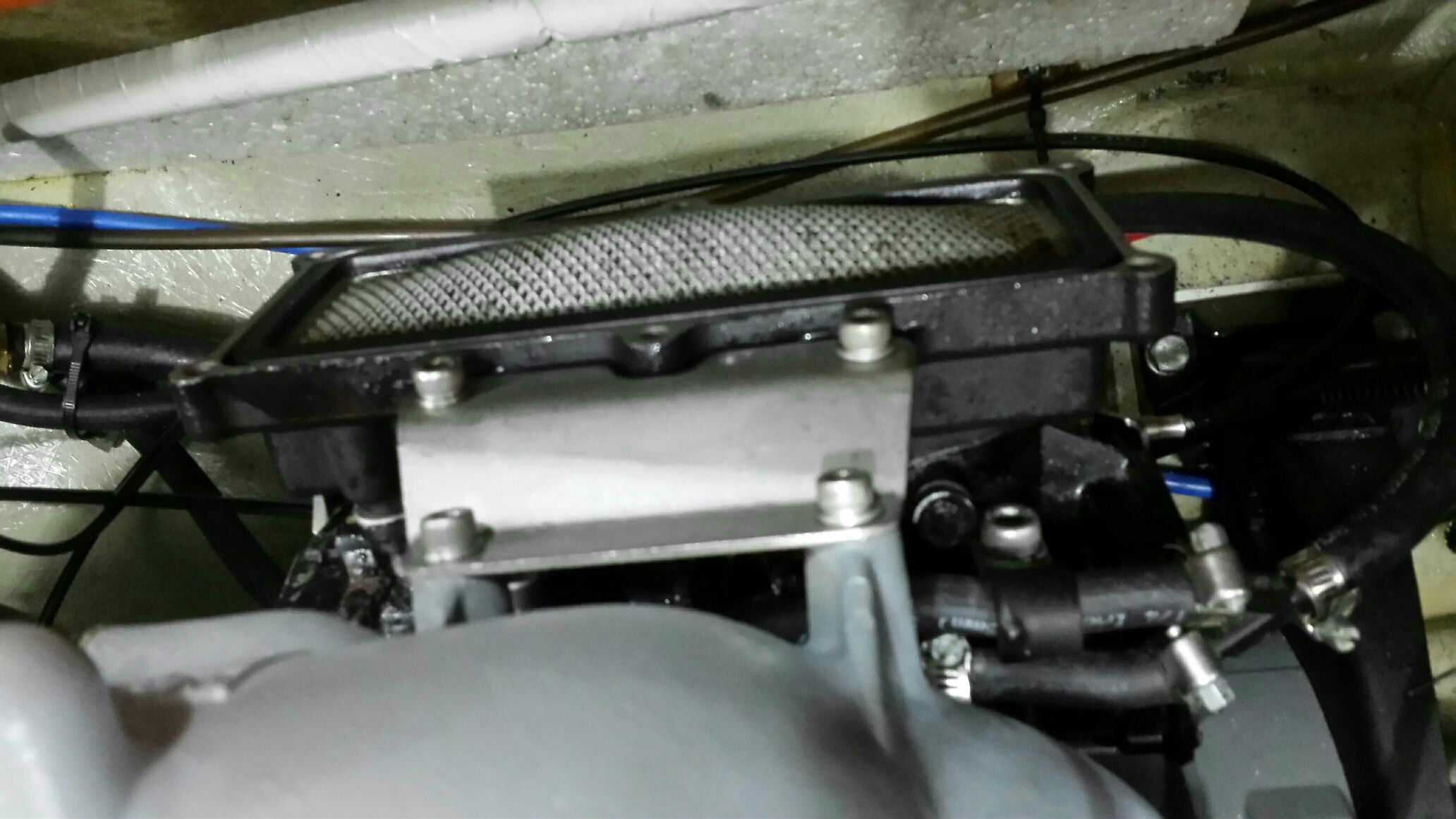

ok i reset the high and low to where they should be (PO HAD IT WAY OUT OF WACK). ski starts off and idles good but when you give it gas it falls right on its face. if i goose it 3-4 times it will pull right out of the water and get it like dale jr! What am i missing? should i run some sea foam through it?

thanks guys

high at 0

lows out 1

thanks guys

high at 0

lows out 1