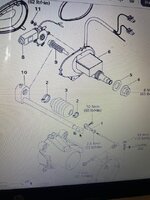

I got the interior of the hull pressure washed today. When I was putting the fuel lines on the selector valve, the RES fitting on the valve rotated, not sure if it’s supposed to or not? This selector valve is different than the ones that were on my HX and 95XP, I wondering if it’s original or a cheap aftermarket one? I did vacuum test the selector valve after the fitting rotated and it didn’t lose vacuum so I’m going to go ahead and use it. Hope I don’t regret that decision.