-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RESTO Our 1st 951 ever!!! Resto

- Thread starter Jetskigoodies

- Start date

- Status

- Not open for further replies.

Jetskigoodies

Well-Known Member

Jetskigoodies

Well-Known Member

This is for sure my keeper. I love how it is turning out.

Spimothy Leary

Well-Known Member

all kinds of sexy with this ski !

Jetskigoodies

Well-Known Member

Thanks alot guys. I have new grips on the way and am having the choke bracket machined. Now I just have to get it running lol

Looking dope man!!

Sent from my HTC6525LVW using Tapatalk

Sent from my HTC6525LVW using Tapatalk

Jetskigoodies

Well-Known Member

Jetskigoodies

Well-Known Member

Thanks Dan, I think I am going to do a xp logo on the air deflector too. I want to wait a couple weeks before I put anything on the paint. There is just so much black on the hood that it needs to be broken up a bit. I have plenty of vinyl left for a few more decals.

Jetskigoodies

Well-Known Member

Jetskigoodies

Well-Known Member

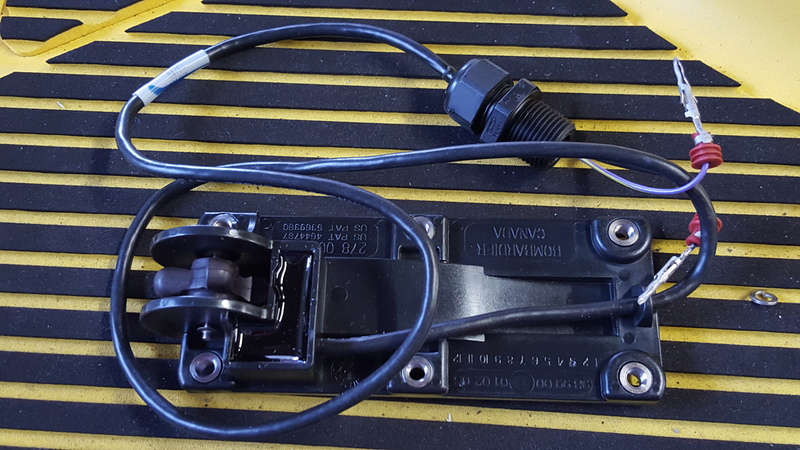

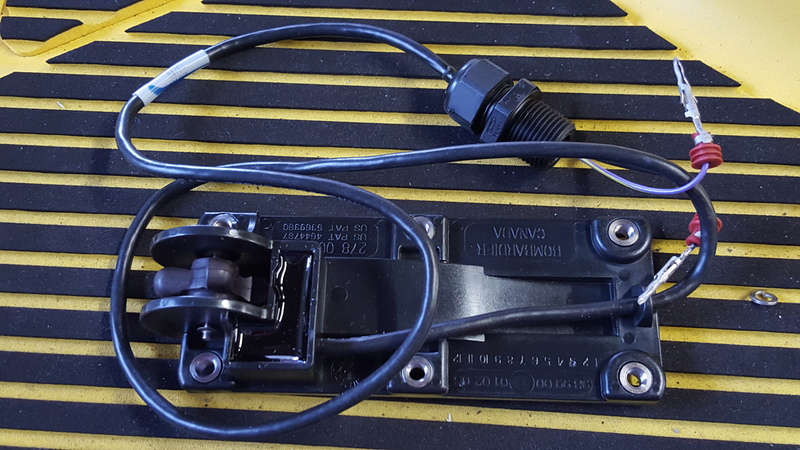

Couple updates.

The choke cable bracket was missing on the umi steering so I had one made. I had to hand file the hole for the cable to slide through but it looks great all together.

Also the speedo wheel was missing on this, so I looked at hole for the wire and noticed someone just cut the wire.

I replaced it with a brand new one.

I also rebuilt the carbs with all new mikuni parts including the needles and seats. They were actually really clean inside, made me wonder why the top end cooked. The jets were updated to the 99 setup and the screws were set right too. It did have pro k's on it.

All that is left is to get this running is putting the carbs and airbox on.

I also am putting in a new bilge pump and relay for it. The bilge pump is melted and the relay was missing. I ordered a brand new relay off ebay and pump from minnetonka.

The choke cable bracket was missing on the umi steering so I had one made. I had to hand file the hole for the cable to slide through but it looks great all together.

Also the speedo wheel was missing on this, so I looked at hole for the wire and noticed someone just cut the wire.

I replaced it with a brand new one.

I also rebuilt the carbs with all new mikuni parts including the needles and seats. They were actually really clean inside, made me wonder why the top end cooked. The jets were updated to the 99 setup and the screws were set right too. It did have pro k's on it.

All that is left is to get this running is putting the carbs and airbox on.

I also am putting in a new bilge pump and relay for it. The bilge pump is melted and the relay was missing. I ordered a brand new relay off ebay and pump from minnetonka.

Last edited by a moderator:

Jetskigoodies

Well-Known Member

Pretty sure I found out why the top end went on this. So I replaced everything inside the carbs but did not get a chance to do the pop off pressure because the pressure gauge was not at the shop. Tonight I did a pop off test and each carb was set at 32 psi, it should be between 19-23psi. So I switched out the springs to get me to 19. That pop off was way to high. That would be why it hesitated in the low range and running at high rpms with that would cause the top end to melt. I mistook the hesitation for the possibility of the filters being dirty because of the grey fuel lines. As soon as I opened these carbs and saw the condition being nearly perfect inside I knew to look elsewhere. So hopefully I tracked down all the problems with this. Will know next week when I test this at the lake.

Jetskigoodies

Well-Known Member

Thanks, we try to do things right the first time. Too bad I did not set the throttle cable right the first time lol. It is a pain to get to after the airbox and pipe go on.

Well today she fired up and rather quickly. Maybe 10 seconds and she fired. It ran away though, had to choke it.

The throttle cable had too much tension. We readjusted the cable and set the rpm to 3000 and it ran great. Then we had to adjust the oil pump cable since we adjusted the throttle. I am ready to ride this thing Sunday. All that is left is to put the vts motor in, tie up all the cables and put the vent tubes in.

Well today she fired up and rather quickly. Maybe 10 seconds and she fired. It ran away though, had to choke it.

The throttle cable had too much tension. We readjusted the cable and set the rpm to 3000 and it ran great. Then we had to adjust the oil pump cable since we adjusted the throttle. I am ready to ride this thing Sunday. All that is left is to put the vts motor in, tie up all the cables and put the vent tubes in.

Jetskigoodies

Well-Known Member

1983

Well-Known Member

Jetskigoodies

Well-Known Member

Sounds good. I will pay tonight. I have the relay just not the bracket

CReynoldsMIZ

Well-Known Member

Let's see a pic with that engine in the hull!

Also, just curious, for your new engines, how do you do your break in? Just curious.

Also, just curious, for your new engines, how do you do your break in? Just curious.

- Status

- Not open for further replies.

Similar threads

- Replies

- 15

- Views

- 364

- Replies

- 0

- Views

- 149

Share: