Krispy

Well-Known Member

Hello all,

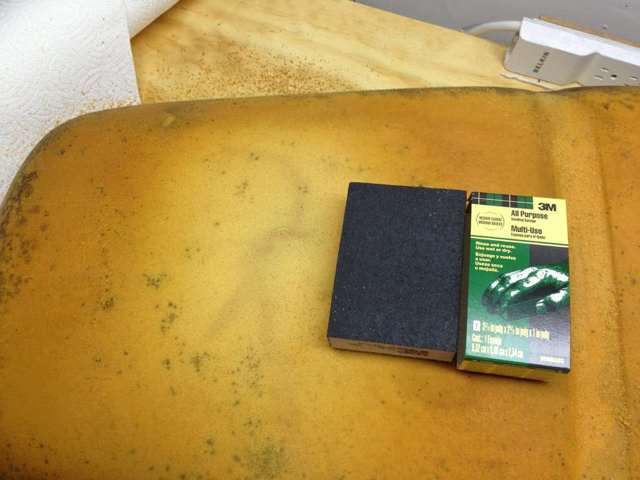

I will be installing a Mline cover tomorrow and I am curious as to if I should remove the original cover or not. I have seen others that left the original seat cover on, however they weren't in as bad shape as mine is see pic below:

My worry is that the damage on my seat is going to cause issues with the look of my new cover.

What do y'all think?

Is there a way to repair before recovering?

I will be installing a Mline cover tomorrow and I am curious as to if I should remove the original cover or not. I have seen others that left the original seat cover on, however they weren't in as bad shape as mine is see pic below:

My worry is that the damage on my seat is going to cause issues with the look of my new cover.

What do y'all think?

Is there a way to repair before recovering?