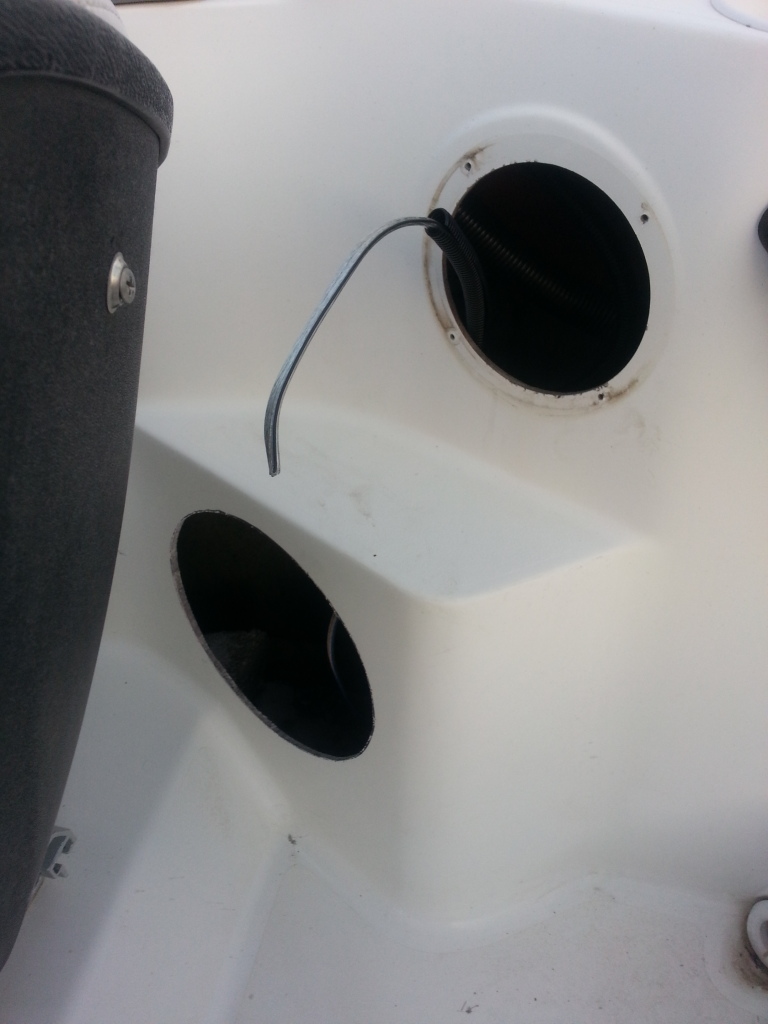

Here is some more stuff I have questions on. I knew the hose from the exhaust fans were beat up and torn and just hanging in the compartment. From the fan i know they go up into the vent hole that sits under the hatch. But the under side of the fan hose is just laying in the engine compartment....I can't find it in the parts diagram...is this normal? Also, anyone ever use a non oem hose for replacement? looks just like dryer vent hose.

Also i think the air intake doesnt seem right. Im guessing this box should be mounted up to where the intake holes are on the side of the boat...its just flopping around inside. I havent looked at the port side yet to compare...it just didnt seem right to me. Seems like the engine would just be using the air in the engine compartment, which seems like a bad idea.

Also i think the air intake doesnt seem right. Im guessing this box should be mounted up to where the intake holes are on the side of the boat...its just flopping around inside. I havent looked at the port side yet to compare...it just didnt seem right to me. Seems like the engine would just be using the air in the engine compartment, which seems like a bad idea.

Last edited by a moderator: