spx787

New Member

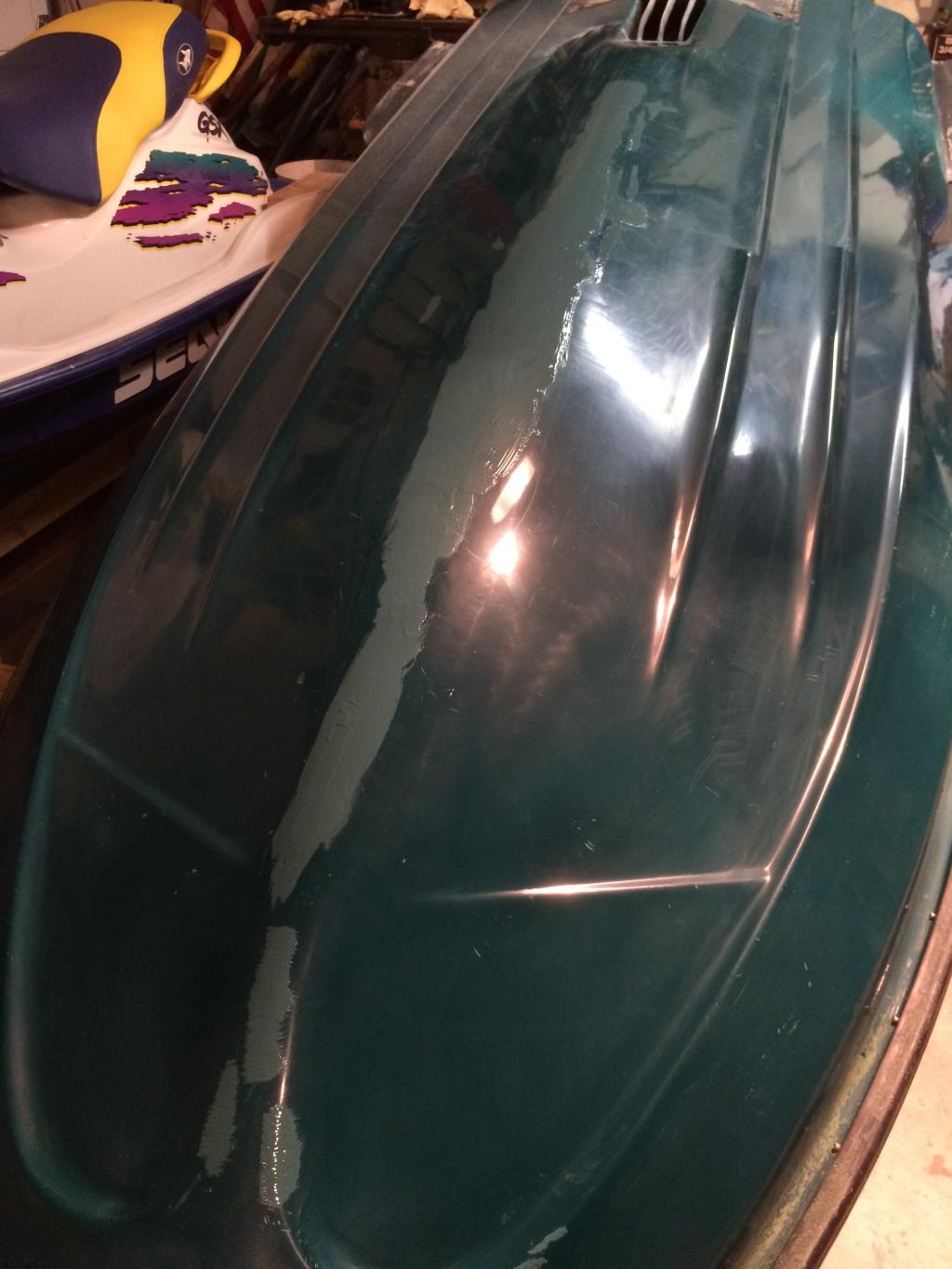

Well I was going to paint it myself. I've done a lot of painting. I was going to a faux carbon fiber look. Google it, it looks pretty good. Anyway, in my research I found that there is some pretty good carbon fiber looking vinyl wrap material. So I am now planning on doing a full wrap of the hood and probably gauge fairing. I will likely paint the mirrors since I doubt I can wrap them. I'm also thinking the glove box may get the same wrap. The seat cover I got is a custom Blacktip with black, silver and white carbon pattern material, so it should all work well together. I'm leaving the bottom dark green. I may add some dark green accents up top to bring it all together. Still working out the final design.

Take it to a vinyl wrap shop if you want the mirrors wrapped. Those dudes can wrap ANYTHING!!!

Also, great thread as I am bringing a 96 GTX back to life myself.