That is a lot of RPM's to be turning. Here is what Harry at Group K says about it so make sure you have a good crank.

Lower End - The crank bearings on the 951 engines have ball bearing separators (aka races) that are made from a Teflon plastic. With heavy high-rpm use, it can happen that these plastic separators break apart and exit an otherwise “good running” engine. If this happens, the crankshaft will eventually begin to eccentrically “run out” for lack of uniform support. This “run out” can cause the engine to slow, vibrate, air-leak, and eventually quit. Since we have seen these bearing cages fail over a wide range of usage hours, so it is impossible to accurately assess their life span. For this reason, we consider the installation of steel caged crank bearings to be absolutely mandatory for any Hammer Kit 951, and highly recommended for all others.

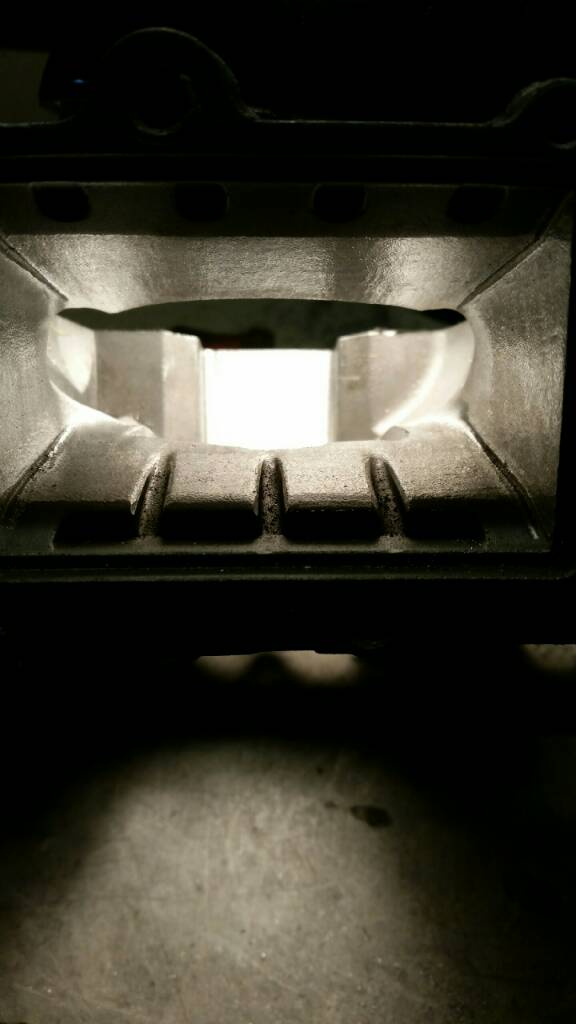

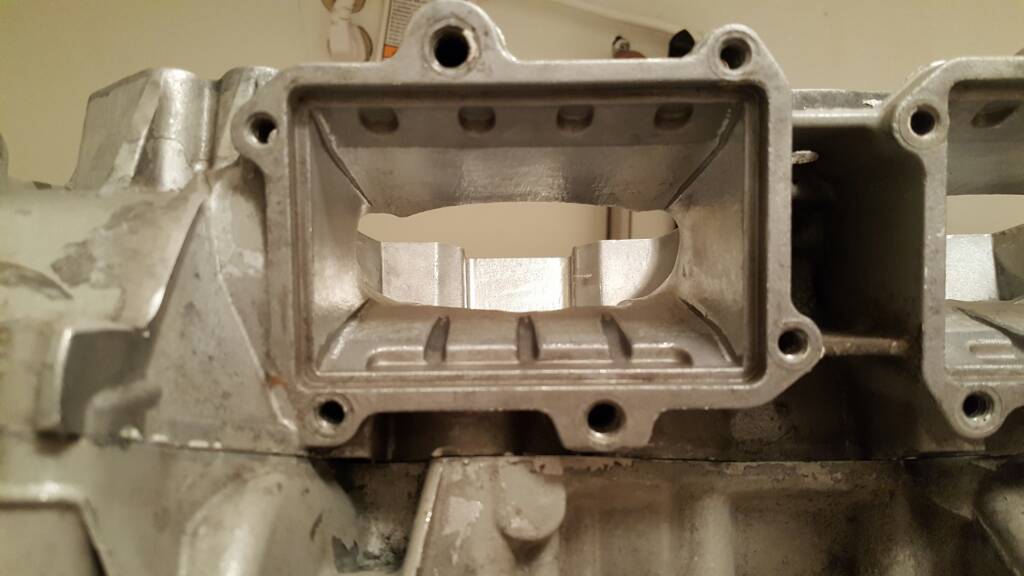

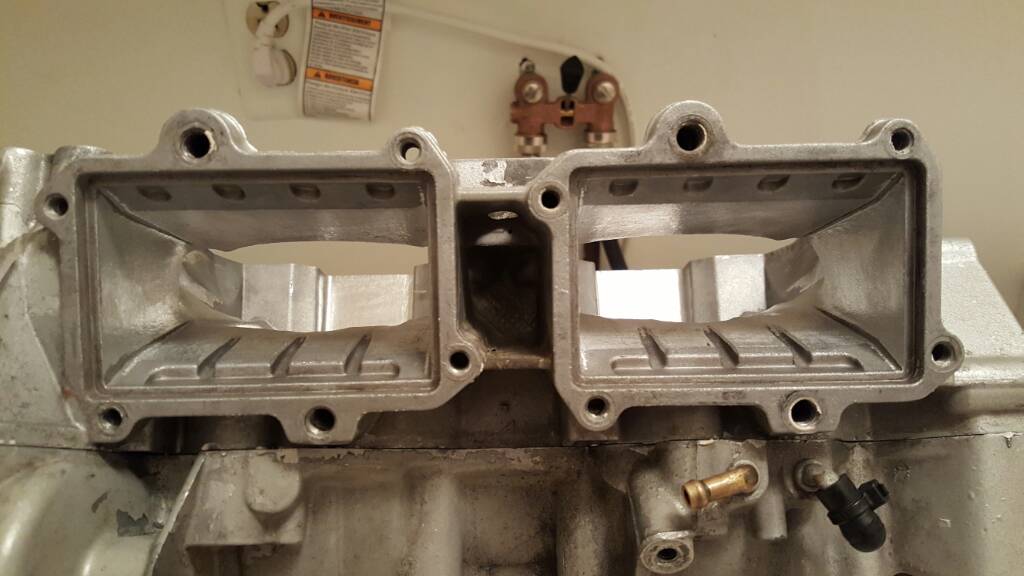

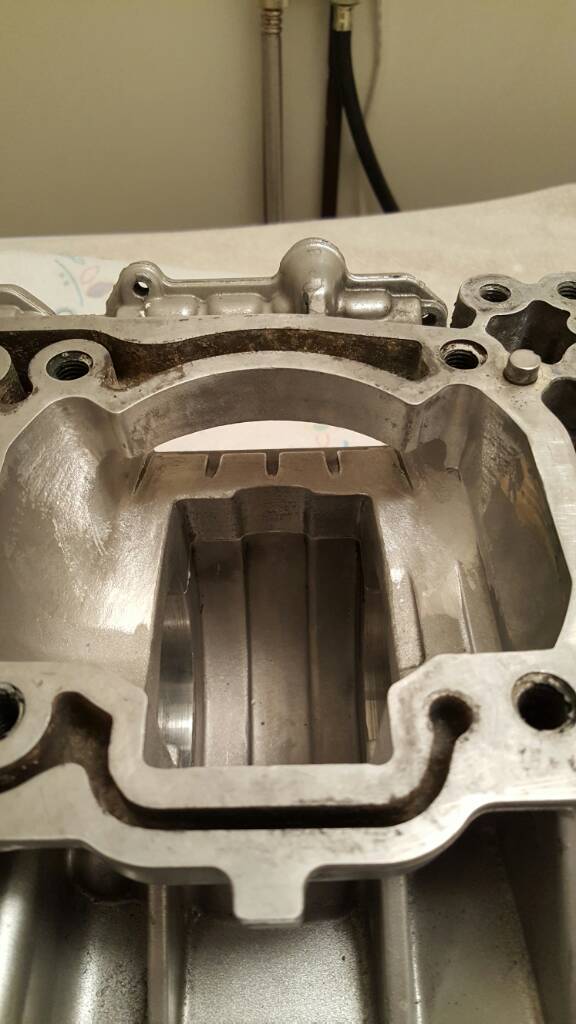

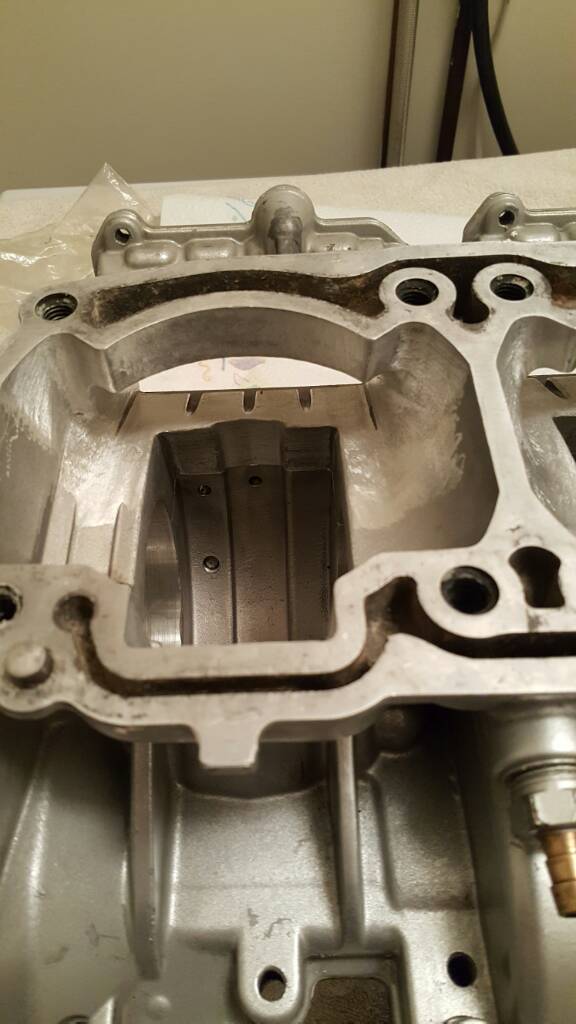

The stock 951 connecting rods are plenty strong enough to contend with the rpms and loads of the Swift Kit and Sleeper Kit. These two kits further benefit the lower end by virtue of the water ingestion protection offered by the stock ‘99 flame arrestor. However the rpms and horsepower loads of the Hammer Kit are enough to represent a reliability risk related to the stock connecting rods. To deal with this reliability problem, crank builders have retro fitted high rpm 951 cranks with Honda 500 motocrosser connecting rods (Please note: we don’t get these parts or do the work, so please don’t call us for specifics on this procedure). Since the Honda rods are slightly shorter than the stock 951 rods, the top crankcase must be machined to assure correct cylinder deck height. Group K will perform this machining operation. While there are some 951 owners that swear they have had no crank difficulties on their 7200+ rpm engines, we still consider this connecting rod/front bearing upgrade to be mandatory for any high rpm 951 platform.