-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Terrible vacation with my doo

- Thread starter jammin777

- Start date

- Status

- Not open for further replies.

Sportster-2001-951C-Stock

Well-Known Member

I think you're taking the best approach under the circumstances, running on the hose while monitoring may reveal something you hadn't noticed previously.

jammin777

Well-Known Member

finally had some time to run some test on the ski today. first while cold ran a compression test mag 145 and pto 150 psi

fuel pressure 62 psi non running, bled down to 45 psi after 2 min, 40 psi 10 min 30 psi 30 min of sitting 60 psi running no matter what rpm. battery volt test 12.8 volts not running 13.15 to 13.23 volts running at 3000 rpm. double checked the oil pump alignment and is spot on.

the idle rpm was 2300 rpm but for some reason after a min of running on the hose, it jumped to 3000 rpm on it's own. blip the throttle and no change, kinda weird. why would that be? after running for 5 min on the hose intake temp was 82f and engine temp at 70f. before i ran it i cleared the codes with the candoo as there wasn't any except the crank sensor not reading signal but that's because it was not running. after running for 5 min no codes came up.

guys i am so stumped at why my ski is hard starting in the water. the one thing that puzzles me is that the sudden jump in rpms as stated above as it has never done that before but i also have never let it idle that long on the trailer as this was the first time on the hose besides the first time i ran it after the rebuild. i also forgot to mention that my fuel tank vent is working as it should and even checked by removing the gas cap when it was acting up at the lake and heard no pressure release at all. i say this as someone mentioned earlier about vapor locking. the only test i forgot to perform is spraying water on the secondary side of the coil.

oh i will say that my starter button while pressing down on it much of the time it will stop cranking and seems like i have to press pretty hard to in-gauge the starter. can that be an issue of hard start? dirty contact? possibly not allowing full flow of current to the ignition? especially under a load on the water? please let it be a possibility. this ski has my head pounding and i am out of ideas.

fuel pressure 62 psi non running, bled down to 45 psi after 2 min, 40 psi 10 min 30 psi 30 min of sitting 60 psi running no matter what rpm. battery volt test 12.8 volts not running 13.15 to 13.23 volts running at 3000 rpm. double checked the oil pump alignment and is spot on.

the idle rpm was 2300 rpm but for some reason after a min of running on the hose, it jumped to 3000 rpm on it's own. blip the throttle and no change, kinda weird. why would that be? after running for 5 min on the hose intake temp was 82f and engine temp at 70f. before i ran it i cleared the codes with the candoo as there wasn't any except the crank sensor not reading signal but that's because it was not running. after running for 5 min no codes came up.

guys i am so stumped at why my ski is hard starting in the water. the one thing that puzzles me is that the sudden jump in rpms as stated above as it has never done that before but i also have never let it idle that long on the trailer as this was the first time on the hose besides the first time i ran it after the rebuild. i also forgot to mention that my fuel tank vent is working as it should and even checked by removing the gas cap when it was acting up at the lake and heard no pressure release at all. i say this as someone mentioned earlier about vapor locking. the only test i forgot to perform is spraying water on the secondary side of the coil.

oh i will say that my starter button while pressing down on it much of the time it will stop cranking and seems like i have to press pretty hard to in-gauge the starter. can that be an issue of hard start? dirty contact? possibly not allowing full flow of current to the ignition? especially under a load on the water? please let it be a possibility. this ski has my head pounding and i am out of ideas.

jammin777

Well-Known Member

well it's been awhile, had time to clear the ol'e noggin. I simply gave it a break as i had a bunch of things i needed to get done around the house.

what ive done today was replace the fuel pressure regulator as i found that it should hold pressure for awhile and the old one didn't. (read post above) so the results of it holding pressure with the new one is excellent! it held pressure for over an hour only down to 52 psi. so what do you think?

now thinking about it as some of you know i had spark plugs issues with fuel fouling while trying to start it in the water resulting a no start issue. could it be because i was giving it throttle while trying to start it this flooding it out? i know on a fuel injected car when running right you shouldn't have to give it throttle to start it right? what i think is the ski should fire right up with out touching the throttle while in the water and when i give it gas, i'm taking a chance of flooding thus wet plugs. let me know what you think even if im off my rocker. maybe it was the bad feul regulator but will not know till i ride it and wont for another week. fingers crossed.

maybe it was the bad feul regulator but will not know till i ride it and wont for another week. fingers crossed.

now my next question is. what should the minimum voltage be while cranking to have spark to fire up? mine on the trailer both plugs in wires on grounding post cranks at a steady 11.7 volts. need to test it while cranking in the water and hopefully can teat that next week if no one is around. im thinking it would probably be less in the water because of the extra load.

i took my battery to work a few days ago and did a load test and tested out perfect. it is a agm with 325 cca.

i ask because in another thread i read that on a 96 787 xp while cranking at 11.7 volts had no spark. after replacing with a new battery, cranking at 12.1 volts had spark! this make me wonder if i have the same issue, battery? starter (denso oem) drawing too many amps/volts? i have a amp clamp meter on the way and will check for that when i get it.

feel free to chime in guys! thanks.

what ive done today was replace the fuel pressure regulator as i found that it should hold pressure for awhile and the old one didn't. (read post above) so the results of it holding pressure with the new one is excellent! it held pressure for over an hour only down to 52 psi. so what do you think?

now thinking about it as some of you know i had spark plugs issues with fuel fouling while trying to start it in the water resulting a no start issue. could it be because i was giving it throttle while trying to start it this flooding it out? i know on a fuel injected car when running right you shouldn't have to give it throttle to start it right? what i think is the ski should fire right up with out touching the throttle while in the water and when i give it gas, i'm taking a chance of flooding thus wet plugs. let me know what you think even if im off my rocker.

now my next question is. what should the minimum voltage be while cranking to have spark to fire up? mine on the trailer both plugs in wires on grounding post cranks at a steady 11.7 volts. need to test it while cranking in the water and hopefully can teat that next week if no one is around. im thinking it would probably be less in the water because of the extra load.

i took my battery to work a few days ago and did a load test and tested out perfect. it is a agm with 325 cca.

i ask because in another thread i read that on a 96 787 xp while cranking at 11.7 volts had no spark. after replacing with a new battery, cranking at 12.1 volts had spark! this make me wonder if i have the same issue, battery? starter (denso oem) drawing too many amps/volts? i have a amp clamp meter on the way and will check for that when i get it.

feel free to chime in guys! thanks.

kicker

Well-Known Member

Wow you are persistent, you will get it figured out sooner or later, we are all rooting for you.

As far as starting with no throttle, you are correct, there is no need to hit the throttle, if your doing this regularity that could be the reason for the fuel soaked plugs. It could also be the reason it jumped from 2300 to 3000................it had to clear out the excess fuel before it could reach proper idle rpm's.

I didnt reread the thread..........did you replace the injectors? Is it possible that one is leaking and loading up the crankcase with fuel too?

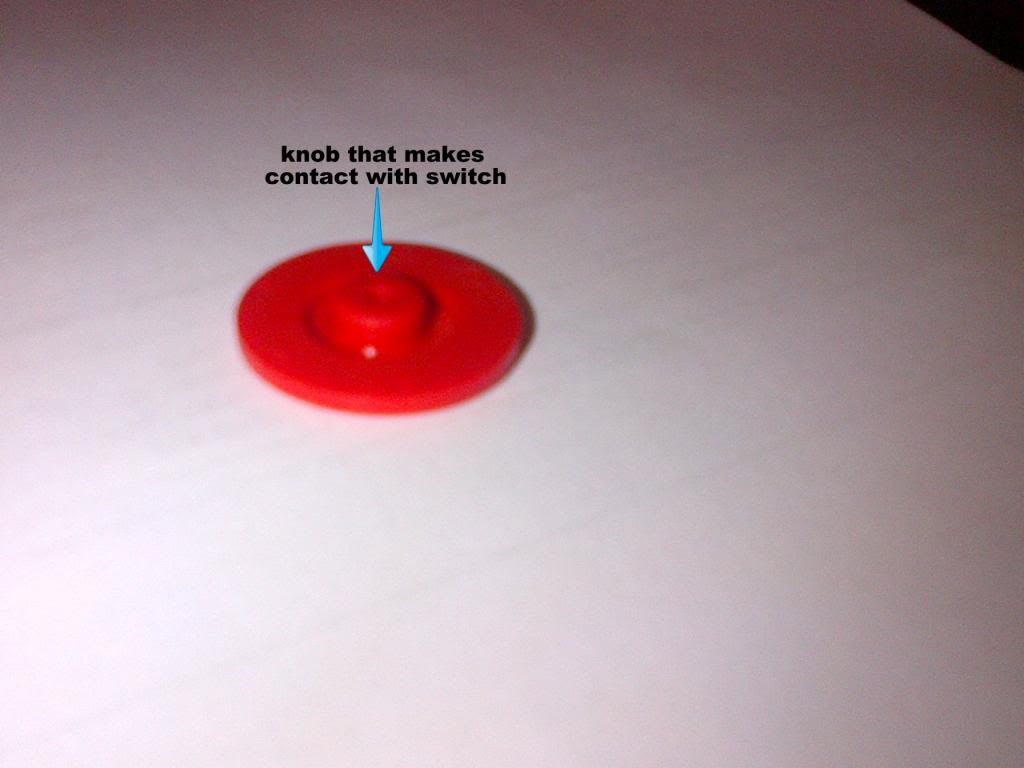

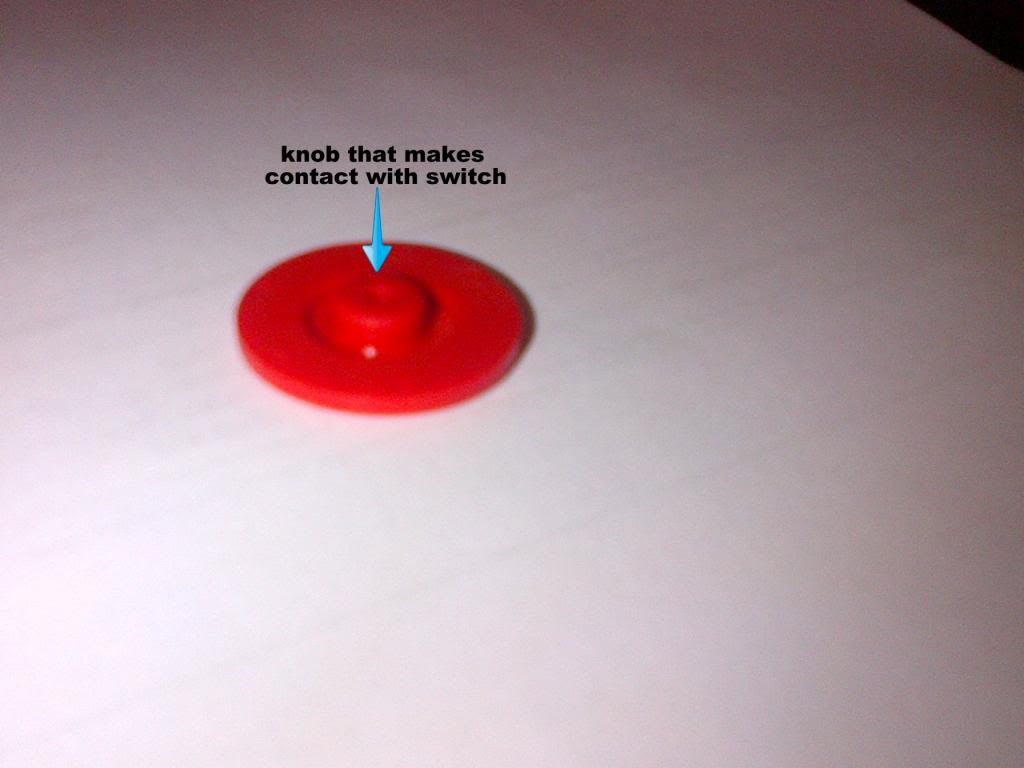

As far as the start button, they do get weak, what I mean is the little rubber nub gets soft and has a hard time pushing the switch properly. It does not happen often that the actual switch (which is under the button) goes bad. You can take the button out and just push the switch to rule out the button not making proper contact with the switch.

It would be interesting to see what the voltage is at while cranking in the water. When flirting with low 11's there is potential for a hard start problem, there is no magical exact voltage, it seems every ski has its own threshold. 11.7 will not be an issue but I would guess, it goes down some more when trying to start in the water. Do you ever get a long beep when it cuts out while cranking it over? That would be a tell tale of a weak battery because the computer is loosing communication with the key.

As far as starting with no throttle, you are correct, there is no need to hit the throttle, if your doing this regularity that could be the reason for the fuel soaked plugs. It could also be the reason it jumped from 2300 to 3000................it had to clear out the excess fuel before it could reach proper idle rpm's.

I didnt reread the thread..........did you replace the injectors? Is it possible that one is leaking and loading up the crankcase with fuel too?

As far as the start button, they do get weak, what I mean is the little rubber nub gets soft and has a hard time pushing the switch properly. It does not happen often that the actual switch (which is under the button) goes bad. You can take the button out and just push the switch to rule out the button not making proper contact with the switch.

It would be interesting to see what the voltage is at while cranking in the water. When flirting with low 11's there is potential for a hard start problem, there is no magical exact voltage, it seems every ski has its own threshold. 11.7 will not be an issue but I would guess, it goes down some more when trying to start in the water. Do you ever get a long beep when it cuts out while cranking it over? That would be a tell tale of a weak battery because the computer is loosing communication with the key.

Sportster-2001-951C-Stock

Well-Known Member

I vote for improved battery cables over the spaghetti noodle thin ones, always money well spent (esp. in salt water) when attempting to crank an engine using these puny cranking batteries. Yeah, a few tenths of volts can make the difference.

I've seen this in skis too many times to ignore the possibility, ignition problems due to low voltage are also consistent with finding unburned fuel in the cylinders/fuel fouled plugs.

In the case of fuel injection, not only does the ignition need adequate voltage but we're firing injectors and running a fuel pump all at the same time as powering a computer while cranking, any losses in the system stack up quickly and can make the difference.

We really need to know minimum peak voltage values as close to the MPEM as possible (a good Fluke meter can do this), or at least on the starter as a minimum.

As for the rest of it such as applying throttle, I have doubts.

Why is it: "There's never enough time to do it right the first time, but there's always enough time to go back and do it over again the right way."

I've seen this in skis too many times to ignore the possibility, ignition problems due to low voltage are also consistent with finding unburned fuel in the cylinders/fuel fouled plugs.

In the case of fuel injection, not only does the ignition need adequate voltage but we're firing injectors and running a fuel pump all at the same time as powering a computer while cranking, any losses in the system stack up quickly and can make the difference.

We really need to know minimum peak voltage values as close to the MPEM as possible (a good Fluke meter can do this), or at least on the starter as a minimum.

As for the rest of it such as applying throttle, I have doubts.

Why is it: "There's never enough time to do it right the first time, but there's always enough time to go back and do it over again the right way."

Last edited by a moderator:

jammin777

Well-Known Member

@ kicker, i did replace the red stater button last winter, no beeps or low voltage warnings on the info center while cranking. it just seems that i have to press hard on the start button to activate the starter and sometimes it cuts out and have to repress the button again as if maybe a dirty or bad contact in the switch itself. yes i did replace the injectors and even pulled the injector rail a couple weeks ago for a drip test and not a single drop in 15 min.

@ sportster, i did replace the ground cable battery to starter with a heavier one, the pos cable was in good condition.

what i did do today is after doing the cranking volt test at the battery, i hooked the gound from the meter to the ground on the mag cover where the ground wires are and still read 11.7 volts cranking. so it seems i dont have a ground issue at least.

how can i go about testing voltage closest to the mpem? can i do this with the meter i have?

also i want to test amp draw from the starter and the fuel pump. i did order a cheap amp clamp meter and want to test to see/diagnose things as i know like as you said, with the rfi there are components that tax the charging system and it appears that there is very little room to run all the things the rfi requires and like you said, a few amps make a huge difference. so i need to know if my starter has a problem drawing too much power while in the water to not spark and fire the injectors, and also fuel pump sence even though it is a bosch, the one i have may be drawing more amps than the original? i have no idea what the specs are for my new fuel pump as compared the the original one. sorry i and really dumb when it comes to electrical. but with help in laymen terms i know i can get it figured out.

but i have pretty much ruled out the fuel system.

one thing that comes to mind is maybe try gaping the plugs to 24 rather than 20 thousands?

what do you think about the new fuel regulator holding pressure for going on 3 hours as appose to the old one dropping quickly?

man guys, thanks for your support and rooting for me! its been a tough journey for sure. i will get this dam ski running right yet even if i have to take to my grave? lol!

@ sportster, i did replace the ground cable battery to starter with a heavier one, the pos cable was in good condition.

what i did do today is after doing the cranking volt test at the battery, i hooked the gound from the meter to the ground on the mag cover where the ground wires are and still read 11.7 volts cranking. so it seems i dont have a ground issue at least.

how can i go about testing voltage closest to the mpem? can i do this with the meter i have?

also i want to test amp draw from the starter and the fuel pump. i did order a cheap amp clamp meter and want to test to see/diagnose things as i know like as you said, with the rfi there are components that tax the charging system and it appears that there is very little room to run all the things the rfi requires and like you said, a few amps make a huge difference. so i need to know if my starter has a problem drawing too much power while in the water to not spark and fire the injectors, and also fuel pump sence even though it is a bosch, the one i have may be drawing more amps than the original? i have no idea what the specs are for my new fuel pump as compared the the original one. sorry i and really dumb when it comes to electrical. but with help in laymen terms i know i can get it figured out.

but i have pretty much ruled out the fuel system.

one thing that comes to mind is maybe try gaping the plugs to 24 rather than 20 thousands?

what do you think about the new fuel regulator holding pressure for going on 3 hours as appose to the old one dropping quickly?

man guys, thanks for your support and rooting for me! its been a tough journey for sure. i will get this dam ski running right yet even if i have to take to my grave? lol!

Sportster-2001-951C-Stock

Well-Known Member

As far as measuring voltage at the MPEM, I believe on that ski the MPEM is grounded directly to the engine block but it's not clear from the schematic, the ground for the MPEM could be inside the e-box where the ignition coils live.

While on the subject, the e-box ground post is a known trouble spot, there is on most seadoos of a certain vintage a post inside the e-box where several grounds are all tied together but get this, that post is made of plastic and there is a screw threaded into this plastic post that over time is known to loosen and allow high resistance for these grounds. That would be the grounds for starter solenoid, both coils, and at least another ring terminal connector going to the engine block and maybe one for the MPEM.

So take a close look at that grounding post in the e-box, the fix for it is to drill a hole through the bottom of the box and put a threaded bolt through with a nut/lock washer on the bottom side, preferably all stainless steel.

So, if you want to measure the voltage directly at the MPEM while cranking, you should first determine which ground feeds it (connector 3 pin 25) and the power itself is on the 5A fuse, so use those test points. You can probe the fuse itself, there is an opening at the top corner of the fuse that's accessable with the fuse installed, look carefully and you'll see the opening there, there are two of them to allow for in-circuit testing.

I'm really not sure how much current you're liable to see with the clamp meter while cranking, it's liable to be quite a bit, so I'm interested in what you find out.

As far as gaping the plugs goes, if the gap is too small then wet fuel can bridge the gap and short out the plug. Our engines run rather rich (2-strokes do this) so it's unnecessary to have a big fat spark to ignite a lean mixture. Our combustion chambers are rather densely packed with a fuel charge under compression so the challenge mostly is to have a small enough gap to successfully force the spark to jump the gap. It can take quite a bit of voltage to force the spark to occur.

So if you make the gap too large you might get no spark (missing) under certain conditions that are harder to fire (such as WOT), or if the gap is too small the fuel bridges the gap and shorts the plug (fuel fouling).

I shoot for 20 thou, under the premise that as the plug wears the gap will open up. Also, a narrow gap is less likely to misfire due to lack of spark but is more easily fuel fouled so if one of my carbs goes pig rich for some reason I expect the fuel will short the plug and I can find a problem early, that way.. But I know what the motor should sound like anyway, so might be a moot point.

I think if you gap the plugs right to the middle of spec you're good to go, two different guys can gap a plug differently depending on his gauge, either a flat feeler or wire. Wire gauges are the best way to go, IMO.

The new fuel regulator holding pressure might help depending on what the previous running pressure was. Since running pressure is what really counts then, if the running pressure hasn't changed then the performance isn't likely to change.

It's just that one way to test a regulator is to examine decay, something like 30 secs or less is likely a bad regulator that has trash like dirt. leaves, or corrosion on the valving surfaces or some other type of corrosion/dirt jamming the works, or it could simply be worn out. Just b/c a regulator holds pressure doesn't mean it's working, what counts is the regulator holds the pressure at some predictable value while the engine uses fuel from the fuel rail. If the regulator was leaking off fast then I'd have to think the pressure would be too low during cruising or WOT, and the engine might run lean enough to roast a piston or misfire.

While on the subject, the e-box ground post is a known trouble spot, there is on most seadoos of a certain vintage a post inside the e-box where several grounds are all tied together but get this, that post is made of plastic and there is a screw threaded into this plastic post that over time is known to loosen and allow high resistance for these grounds. That would be the grounds for starter solenoid, both coils, and at least another ring terminal connector going to the engine block and maybe one for the MPEM.

So take a close look at that grounding post in the e-box, the fix for it is to drill a hole through the bottom of the box and put a threaded bolt through with a nut/lock washer on the bottom side, preferably all stainless steel.

So, if you want to measure the voltage directly at the MPEM while cranking, you should first determine which ground feeds it (connector 3 pin 25) and the power itself is on the 5A fuse, so use those test points. You can probe the fuse itself, there is an opening at the top corner of the fuse that's accessable with the fuse installed, look carefully and you'll see the opening there, there are two of them to allow for in-circuit testing.

I'm really not sure how much current you're liable to see with the clamp meter while cranking, it's liable to be quite a bit, so I'm interested in what you find out.

As far as gaping the plugs goes, if the gap is too small then wet fuel can bridge the gap and short out the plug. Our engines run rather rich (2-strokes do this) so it's unnecessary to have a big fat spark to ignite a lean mixture. Our combustion chambers are rather densely packed with a fuel charge under compression so the challenge mostly is to have a small enough gap to successfully force the spark to jump the gap. It can take quite a bit of voltage to force the spark to occur.

So if you make the gap too large you might get no spark (missing) under certain conditions that are harder to fire (such as WOT), or if the gap is too small the fuel bridges the gap and shorts the plug (fuel fouling).

I shoot for 20 thou, under the premise that as the plug wears the gap will open up. Also, a narrow gap is less likely to misfire due to lack of spark but is more easily fuel fouled so if one of my carbs goes pig rich for some reason I expect the fuel will short the plug and I can find a problem early, that way.. But I know what the motor should sound like anyway, so might be a moot point.

I think if you gap the plugs right to the middle of spec you're good to go, two different guys can gap a plug differently depending on his gauge, either a flat feeler or wire. Wire gauges are the best way to go, IMO.

The new fuel regulator holding pressure might help depending on what the previous running pressure was. Since running pressure is what really counts then, if the running pressure hasn't changed then the performance isn't likely to change.

It's just that one way to test a regulator is to examine decay, something like 30 secs or less is likely a bad regulator that has trash like dirt. leaves, or corrosion on the valving surfaces or some other type of corrosion/dirt jamming the works, or it could simply be worn out. Just b/c a regulator holds pressure doesn't mean it's working, what counts is the regulator holds the pressure at some predictable value while the engine uses fuel from the fuel rail. If the regulator was leaking off fast then I'd have to think the pressure would be too low during cruising or WOT, and the engine might run lean enough to roast a piston or misfire.

jammin777

Well-Known Member

thanks sportster, you explained well and now understand. i will check into all the grounds you mention and will let you know what i find when i get the amp meter. if i remember right it seamed that my ski started easily when i had the spark plug gap set at 24. back in june before i took my vacation when i noticed the bog during break in, i pulled into shore and re gaped the plugs to 20 and thats when i believe i started experiencing the hard starts. at that time i was trying to remedy the bog which proved to be the rave bellows holding the raves open. before i re gaped the plugs it was a bit hard starting and had to give it a little throttle to get her to fire up but nothing like it has been. but still there is definitely an issue i hope to solve soon.

as for the fuel regulator, what you say make sense. the fuel pressure was spot on even with the old regulator, it just wasn't holding the pressure with the dess key pulled. plus once it was running it ran great.

as for the fuel regulator, what you say make sense. the fuel pressure was spot on even with the old regulator, it just wasn't holding the pressure with the dess key pulled. plus once it was running it ran great.

Sportster-2001-951C-Stock

Well-Known Member

Yeah, I really don't see any problem with setting the gap to 24 thou,that's what I was trying to say. If you notice an improvement then go with it, won't hurt to leave them at 24, that's my feeling.

68ragtop

Well-Known Member

I am guessing we covered this already, but is there any chance the starter is weak & is either spinning slower than it should be, or drawing excessive current? My 800 carb'd skis drew pretty heavy current when cranking. No gear reduction on them & maybe a borderline amount of engine to spin over for those starters? I think the 800's have a bigger flywheel though, so maybe the starter to crankshaft final drive ratio is the same? I'm not sure on that one. just thinking out loud.

Pretty sure my old 800's would drop voltages under 11V while cranking. Healthy AGM 320 batteries at the time.

Pretty sure my old 800's would drop voltages under 11V while cranking. Healthy AGM 320 batteries at the time.

Sportster-2001-951C-Stock

Well-Known Member

Yep, I wanna see what the new regulator does for him, one thing at a time kinda strategy. Not seadoos but others, I've seen fuel pressure still in spec but at low end of spec that was insufficient for a good start and a spray of fuel for cranking was all it took to get things rolling.

So yeah, all of the above.

So yeah, all of the above.

jammin777

Well-Known Member

starter is cranking at the right speed in or out of water, not much difference but not sure if it is drawing too much amperage while cranking in the water as i'm sure the starter has to be working harder in the water but speed is good. i'm going to try to take it out this weekend and run voltage test and fuel test and see what the voltage in the water is while cranking. by the way the new fuel regulator is at 45 psi after 2 days. the old one dropped to 5- 10 psi during the same amount of time. maybe ill get lucky and ride it too. hopefully no one will be around to pest me at the ramp lol!

hopefully no one will be around to pest me at the ramp lol!

PGHMAN

Active Member

starter is cranking at the right speed in or out of water, not much difference but not sure if it is drawing too much amperage while cranking in the water as i'm sure the starter has to be working harder in the water but speed is good. i'm going to try to take it out this weekend and run voltage test and fuel test and see what the voltage in the water is while cranking. by the way the new fuel regulator is at 45 psi after 2 days. the old one dropped to 5- 10 psi during the same amount of time. maybe ill get lucky and ride it too.hopefully no one will be around to pest me at the ramp lol!

Kevin, our fingers and toes are crossed. Curious, what fuel regulator did you purchase?

68ragtop

Well-Known Member

starter is cranking at the right speed in or out of water, not much difference but not sure if it is drawing too much amperage while cranking in the water as i'm sure the starter has to be working harder in the water but speed is good. i'm going to try to take it out this weekend and run voltage test and fuel test and see what the voltage in the water is while cranking. by the way the new fuel regulator is at 45 psi after 2 days. the old one dropped to 5- 10 psi during the same amount of time. maybe ill get lucky and ride it too.hopefully no one will be around to pest me at the ramp lol!

Safe to say again that your injectors are not leaking then......

jammin777

Well-Known Member

e herko on ebay. oh and my hairs are crossed too lol!Kevin, our fingers and toes are crossed. Curious, what fuel regulator did you purchase?

jammin777

Well-Known Member

well i never had a chance to take the ski out for the last time this year for testing and or for a ride. been too busy or bad weather. sometime during the winter i plan to replace the coil pack + wires and test/ rebuild the starter as well as comb it thru and re check all connections. with all Ive done so far, i should have it narrowed down. i plan to take her out for testing early to mid spring before the ramps get busy and do what i can to make up for lost time. i promise to resurrect this thread next year with results. got her on the shop cart, next, winterize. thanks to all that took the time.

been too busy or bad weather. sometime during the winter i plan to replace the coil pack + wires and test/ rebuild the starter as well as comb it thru and re check all connections. with all Ive done so far, i should have it narrowed down. i plan to take her out for testing early to mid spring before the ramps get busy and do what i can to make up for lost time. i promise to resurrect this thread next year with results. got her on the shop cart, next, winterize. thanks to all that took the time.

- Status

- Not open for further replies.

Similar threads

- Replies

- 28

- Views

- 671

- Replies

- 13

- Views

- 389