am i right that a failing coil could act up more when hot?

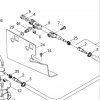

on the rfi's the injector is mounted on the side of the cylinders mid way down.

the weird thing is, back to the maiden voyage, it started easily the 1st 2 outings without fail. it has gotten progressively worse as time gone by since my camping trip in july just before i fixed my rave issue.

Yes, typically heat does expose a weak coil and over time they get weaker and weaker. So it is consistent except there are two coils and it's doubtful in my pea brain both are bad.

I would disable the carbon seal retainer and test run on the hose.

If the sensor calibration, any sensor, is off by just enough it can run like crap and still never throw a code (from my indirect experience with many FI systems, not direct experience with RFI). The codes are obvious once the sensor is completely FUBAR, such as disconnected.

Your pressure and temp sensor work in conjunction with the TPS sensor to help the MPEM to deliver the optimum air/fuel ratio.

One method to finding a damaged sensor can be to disconnect the sensor and the PCM will throw a code while running (better) off a default value (might default to a limp mode). For instance, a MAF sensor is good for measuring flow at wide throttle settings and the redundant sensor is the manifold pressure sensor that is useful at all throttle settings but not as accurate at high throttle settings.

If by unplugging the MAF sensor fixes idle stumbles and poor drivability then the MAF sensor is a likely problem.

So, it's important to verify a sensor output is normal under operating conditions. For example, if your temp sensor says 70*F before startup and after reaching normal operating temp then reads -20*F that sensor circuit is not working properly. The PCM S/W might average two sensors and thus doesn't know which sensor is at fault thus runs like poo due to funky mixture yet no fault code.

This is an example of "software sucks".