You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RESTO I want to convert my 1996 seadoo gti to fuel injection

- Thread starter MATT467

- Start date

- Status

- Not open for further replies.

Sportster-2001-951C-Stock

Well-Known Member

I agree, you won't want to go that route once you look into how difficult and impossible it will be, you could buy a 4-stroke injected 4-tec for the price of parts probably.

Muy Importante low hanging fruit is make sure there's no air leaks in your fuel lines and verify you can actually pump fuel from the tank and your fuel pump works (fuel pump test), then go back into those carbs and pay close attention to the small passages of the low speed circuit, three small holes in the carburetor bore and the passage feeding them fuel are SUPER important and difficult to clean many times, people just can't seem to get them cleaned out and end up buying NEW carbs.

These ALUMINUM carbs don't have any kind of protective chromate coating on them and they're made of aluminum which can become corroded in those tiny passages so you may need to use a phosphoric dip to get those passages cleaned out.

http://oldcarblog.com/?p=15

Or buy new ones, you're not the only guy who ran into a Mikuni carb that's difficult to restore. Many cases of that in these hallowed halls.

Muy Importante low hanging fruit is make sure there's no air leaks in your fuel lines and verify you can actually pump fuel from the tank and your fuel pump works (fuel pump test), then go back into those carbs and pay close attention to the small passages of the low speed circuit, three small holes in the carburetor bore and the passage feeding them fuel are SUPER important and difficult to clean many times, people just can't seem to get them cleaned out and end up buying NEW carbs.

These ALUMINUM carbs don't have any kind of protective chromate coating on them and they're made of aluminum which can become corroded in those tiny passages so you may need to use a phosphoric dip to get those passages cleaned out.

http://oldcarblog.com/?p=15

Or buy new ones, you're not the only guy who ran into a Mikuni carb that's difficult to restore. Many cases of that in these hallowed halls.

MATT467

New Member

Thanks for all the info guys. When I rebuilt the carbs, I used after market parts. Now I'm just going to do it again with OEM parts. I also think the problem is the pop off pressure( can only get it up to 15mph). I noticed the after market spring in the carb was longer. I think that is the culprit. Also is the 787 engine in my seadoo. It's a 96 dual carb gti

Sportster-2001-951C-Stock

Well-Known Member

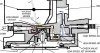

Okay, be sure to check and clean those tiny passages called bypass ports in this drawing, that entire low speed circuit needs to be cleaned and good luck b/c those holes are precision drilled to a specific diameter, the passage tends to clog with junk and the aluminum corrodes a bit which of course causes the bypass holes to become smaller and more restrictive. Smaller and more restrictive means less fuel and thus, lean hesitation where the engine falls on it's face during acceleration b/c it runs out of fuel due to the passages are clogged.

And yes, you want the pop-off pressure to be where it should be for your particular model, that's fairly critical otherwise you may have either not enough fuel up high or way too much down low, hard starting due to flooding out or too difficult to open needle valve (lack of fuel control). It has to be near correct specification b/c vacuum operates the round diaphragm, this pushes the spring-loaded arm and lifts the metering needle off the inlet seat allowing fuel into the small chamber. If this isn't set right it won't fuel correctly. Not just any spring will do, you need the correct one and there are several different ones used depending on which motor, carburetor and air box (flame arrestor) these are all carefully tuned.

Remove the kidney shaped metering plate and under that you'll see the two brass jets. These are calibrated to control maximum flow, don't drill them or damage them, brass generally doesn't corrode and they're fine..

The metering plate will have a thin mylar plastic reed check valve attached with a screw covering a hole, this piece of mylar film is a specific thickness and the aftermarket kits are usually wrong thus the valve opens late. If the mylar reed looks good and laying flat over the hole no need to change it unless you see some kind of problem like it's bent or wrinkled or the hole is clogged. You want an OEM mikuni piece here if you replace it. I usually don't mess with it b/c it's normally not messed up.

Attached drawing:

The red and green lines in this drawing are the low speed circuit, I suggest removing the smaller brass pilot jet and idle mixture needle valve (AKA: low speed adjuster) while cleaning this passage to allow for garbage and corrosion to be blown out.

The blue line represents the high speed circuit, it's rather large and doesn't clog as easily but clean that too, sometimes junk gets caught in the larger brass high speed jet, like a big chunk of some kind of garbage. So blow that out with several good blasts of air (I use ~100psi air for all these passages) make sure nothing's in there as well.

You might still need to use some phosphoric cleaner to clean that low speed circuit (Pilot holes especially) due to just a tiny imperceptible bit of corrosion restricts fuel and changes the calibration resulting in lean hesitation.

Google and download the "Mikuni SBN owners manual" for some more general detail about this series of carbs and how they work but use the specs provided by Seadoo for your particular details such as pop pressure, jet orifice size, metering needle seat orifice size and mixture adjuster needle settings.

Hopefully this helps shed some light on the subject, don't want to cause confusion.

And yes, you want the pop-off pressure to be where it should be for your particular model, that's fairly critical otherwise you may have either not enough fuel up high or way too much down low, hard starting due to flooding out or too difficult to open needle valve (lack of fuel control). It has to be near correct specification b/c vacuum operates the round diaphragm, this pushes the spring-loaded arm and lifts the metering needle off the inlet seat allowing fuel into the small chamber. If this isn't set right it won't fuel correctly. Not just any spring will do, you need the correct one and there are several different ones used depending on which motor, carburetor and air box (flame arrestor) these are all carefully tuned.

Remove the kidney shaped metering plate and under that you'll see the two brass jets. These are calibrated to control maximum flow, don't drill them or damage them, brass generally doesn't corrode and they're fine..

The metering plate will have a thin mylar plastic reed check valve attached with a screw covering a hole, this piece of mylar film is a specific thickness and the aftermarket kits are usually wrong thus the valve opens late. If the mylar reed looks good and laying flat over the hole no need to change it unless you see some kind of problem like it's bent or wrinkled or the hole is clogged. You want an OEM mikuni piece here if you replace it. I usually don't mess with it b/c it's normally not messed up.

Attached drawing:

The red and green lines in this drawing are the low speed circuit, I suggest removing the smaller brass pilot jet and idle mixture needle valve (AKA: low speed adjuster) while cleaning this passage to allow for garbage and corrosion to be blown out.

The blue line represents the high speed circuit, it's rather large and doesn't clog as easily but clean that too, sometimes junk gets caught in the larger brass high speed jet, like a big chunk of some kind of garbage. So blow that out with several good blasts of air (I use ~100psi air for all these passages) make sure nothing's in there as well.

You might still need to use some phosphoric cleaner to clean that low speed circuit (Pilot holes especially) due to just a tiny imperceptible bit of corrosion restricts fuel and changes the calibration resulting in lean hesitation.

Google and download the "Mikuni SBN owners manual" for some more general detail about this series of carbs and how they work but use the specs provided by Seadoo for your particular details such as pop pressure, jet orifice size, metering needle seat orifice size and mixture adjuster needle settings.

Hopefully this helps shed some light on the subject, don't want to cause confusion.

Attachments

wfo speedracer

Active Member

You can buy new carbs at a fraction of the cost of the ones from Seadoo at any WSM or WPS dealer

MATT467

New Member

How much would they be. I need twin carbs for a 96 gtiYou can buy new carbs at a fraction of the cost of the ones from Seadoo at any WSM or WPS dealer

wfo speedracer

Active Member

They do not offer that specific set because 720 with twin carbs were only made for two years, you could step up to 40mm SBN I body carbs they will bolt on but you would have to rejet them.

96spxpos

Well-Known Member

[MENTION=65307]Sportster-2001-951C-Stock[/MENTION] , those bypass ports, I've never physically cleaned them myself. I see that pic is a cross section. where are these actually located? are these the little TINY holes inside of the carb throat? and are they closer to the bottom or top? meaning, can you access it easier from the manifold side or the flame arrestor side?

Thanks

Thanks

wfo speedracer

Active Member

Sportster-2001-951C-Stock

Well-Known Member

[MENTION=65307]Sportster-2001-951C-Stock[/MENTION] , those bypass ports, where are these actually located? are these the little TINY holes inside of the carb throat?

Yes, those are the most important passage in the carburetor b/c 90% of the fuel consumed comes from them unless you ride WOT all the time.

The holes are circled in red in this photo. If they're clogged even a tiny bit you will experience hesitation and this leads to detonation due to the lean mixture riding around part throttle. The big main venturi only begins flowing fuel at throttle angles greater than about %50% or more (depending on model, 951 it's about 70% throttle).

So these holes are the problem almost always, look how small they are it doesn't take much, just a little corrosion to cause a restriction and totally throw off the part-throttle mixture calibration. You can manipulate pop pressure all day long and never compensate for one of these being partly restricted.

Anyway, you've got to restore flow through these holes otherwise you're wasting your time.

The green circle is the idle fuel discharge port. The idle mixture screw feeds this one so you can adjust the idle fuel mixture for an easy hot restart and idling around so it doesn't load up on fuel and choke out. Gotta get that balanced, usually idle mixture is pretty good with this screw set to factory spec unless this port is clogged with junk.

Idle mixture won't have much effect on part throttle but having it just a hair on the rich side keeps enough fuel in the crankcase just the same as an accelerator pump gives that initial extra fuel needed the instant the throttle is cracked open and vacuum drops for the 1st split second. Stick to factory setting for idle mixture screw adjustment, it should be very close to perfect.

Just sayin', getting these bypass (off-idle part throttle transition) holes cleaned out makes the difference between success and fail. And I mean clean, as in back to original diameter.

Attachments

Mickirig1

Well-Known Member

The sticky on carbs at top of the page has procedure for cleaning the holes with carb cleaner. I did it and you could see the change in flow as they cleared of gunk! Blasts of compressed air helps too. Sometimes no matter what you do the carb is done. Someone over the years did not protect the fuel system from old fuel or water. The gaskets even new, could be bad or you pinched one. I had what looked like gray sand in one carb. It was everywhere in the carb. Just kept cleaning it and it came out great.

Sportster-2001-951C-Stock

Well-Known Member

The rods work wonders even after blasts of carb cleaner there were still deposits on the rods they are the exact size of the passages

This is true, the goal is to restore the diameter of those holes and mechanical cleaning is a valid strategy.

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 70

- Replies

- 1

- Views

- 78

- Replies

- 7

- Views

- 402

Share: