IDoSeaDoo

Well-Known Member

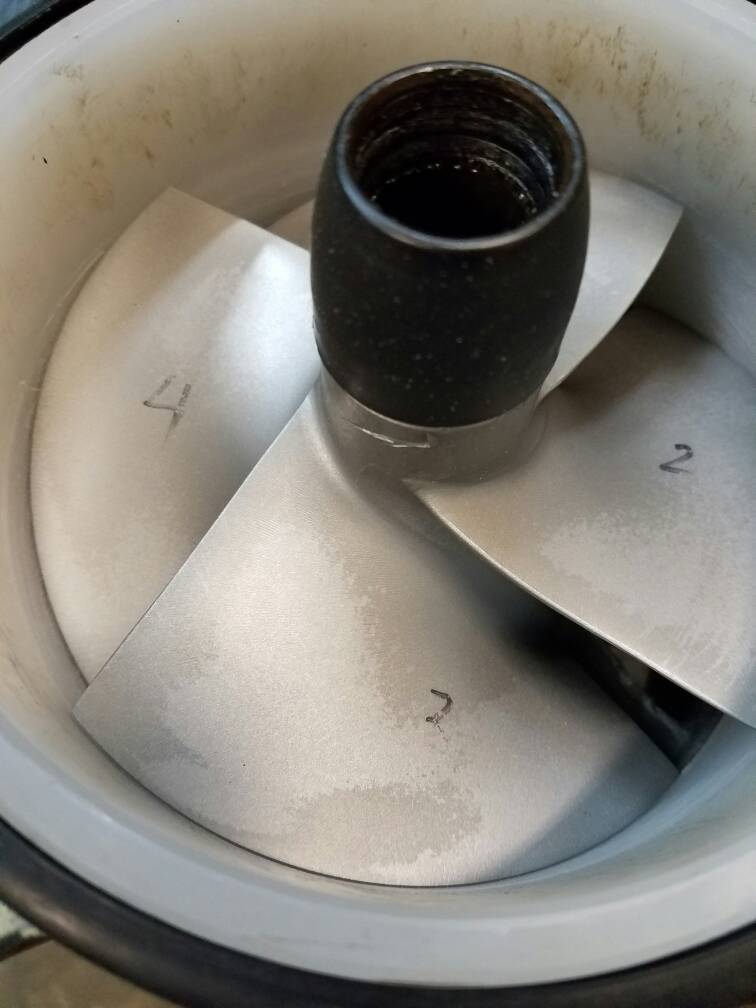

The carbon seal has arrived. I'm going to install a thick o-ring behind the accordion boot to give me extra tension in case the boot has lost some of its spring. Also, my oil catch can should be arriving today or tomorrow. Got to make a wal-mart run for that metal scrub stuff.

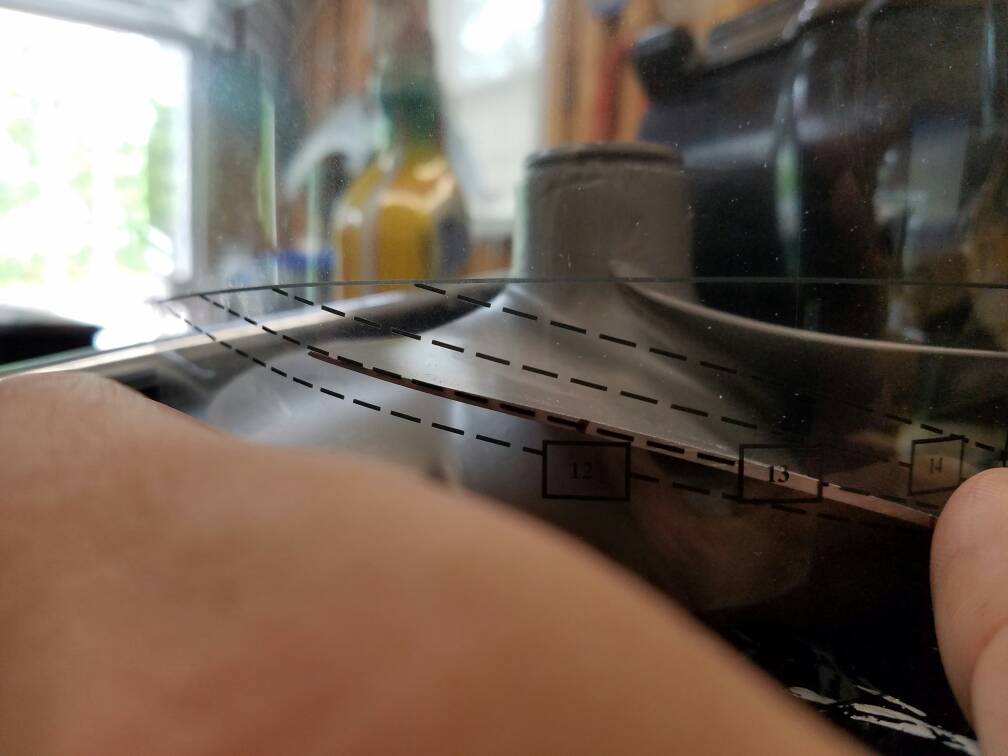

I'm really starting to worry that I will not be able to find the right color of vinyl for this boat. I have searched every single retail store on the internet. Nobody has this color of Teal. And looking at all the rest, I realize that this one is the best teal out there. I'm puzzled over many of the colors I find. Who would want these boring dead-body hues on a BOAT?? The old seadoos had such an awesome color, why is it not available?

I spoke with Keith from Seadoo upholstery, and he seems to know what color it is. But looking at his site, the color of the challenger in his pic is of a different teal. It too is one of the more blue ones

I'm really starting to worry that I will not be able to find the right color of vinyl for this boat. I have searched every single retail store on the internet. Nobody has this color of Teal. And looking at all the rest, I realize that this one is the best teal out there. I'm puzzled over many of the colors I find. Who would want these boring dead-body hues on a BOAT?? The old seadoos had such an awesome color, why is it not available?

I spoke with Keith from Seadoo upholstery, and he seems to know what color it is. But looking at his site, the color of the challenger in his pic is of a different teal. It too is one of the more blue ones