1of500

Well-Known Member

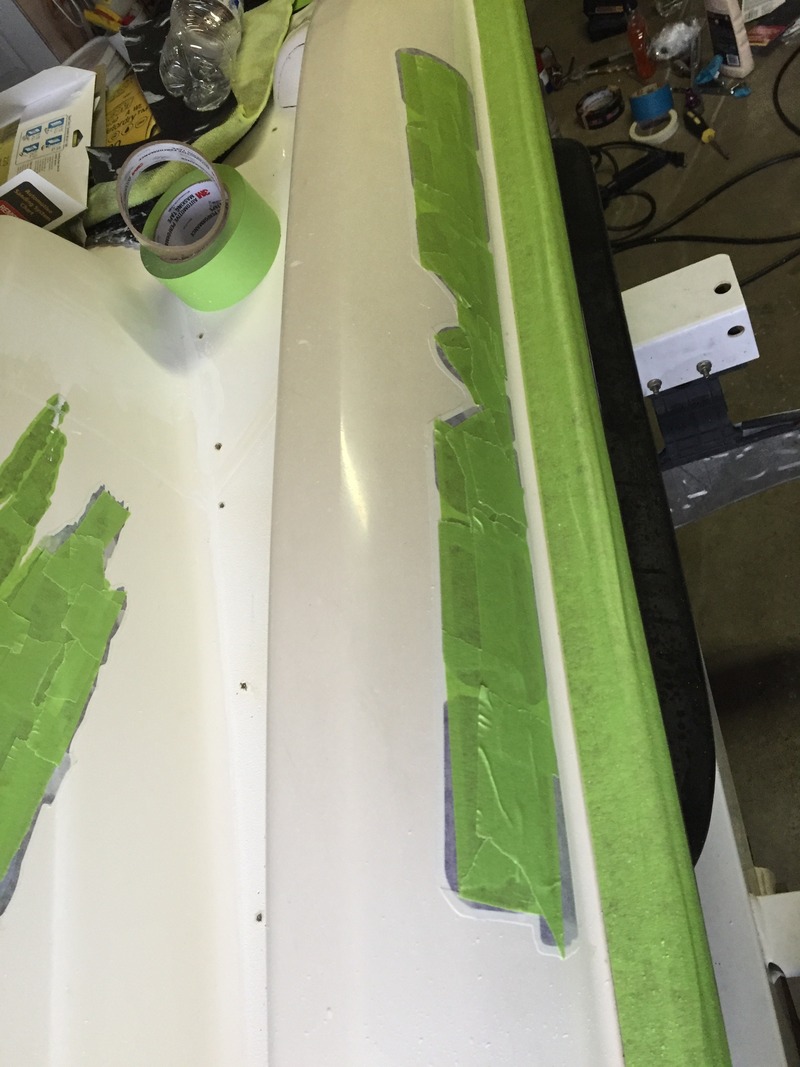

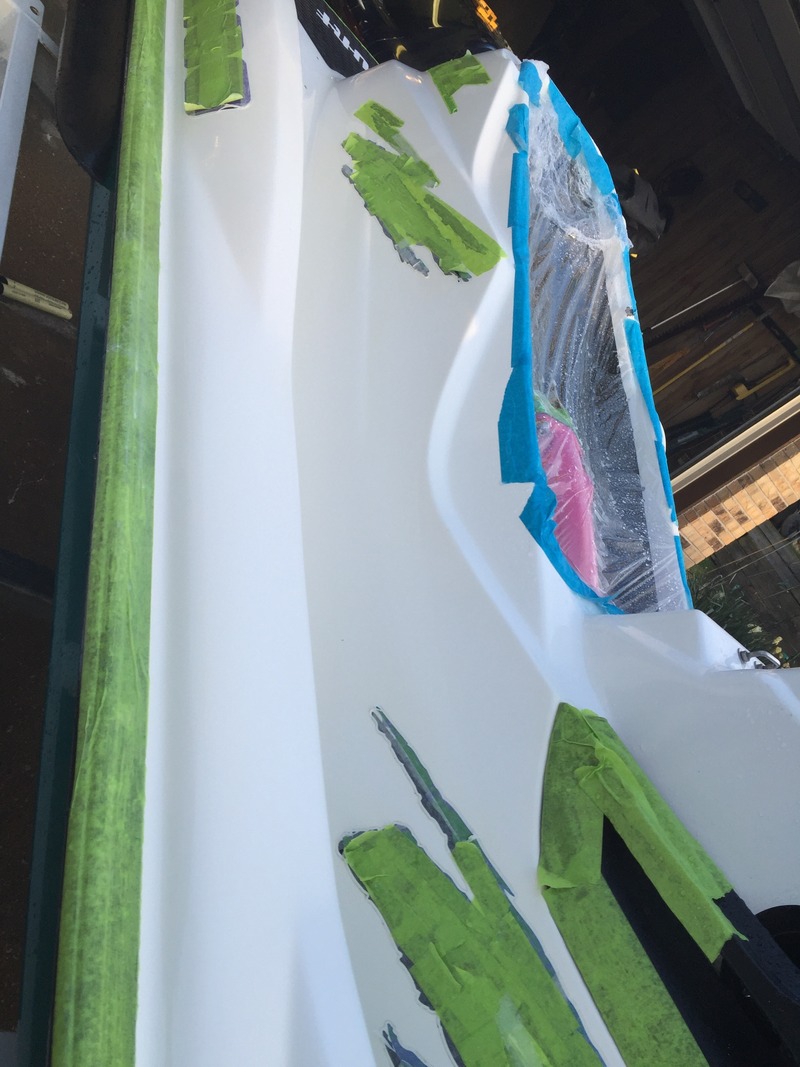

Maybe he's talking about an hour Canadian time [emoji23]Lol, I have hours into the hood on my HX, and even more on the hull and deck. I didn't keep track of the days I have into my 95. If you can sand an X4 in an hour I'll load a trailer up and pay you $150 an hour to do a ski with a 1 hour maximum per ski.[emoji12]