digital sol

Member

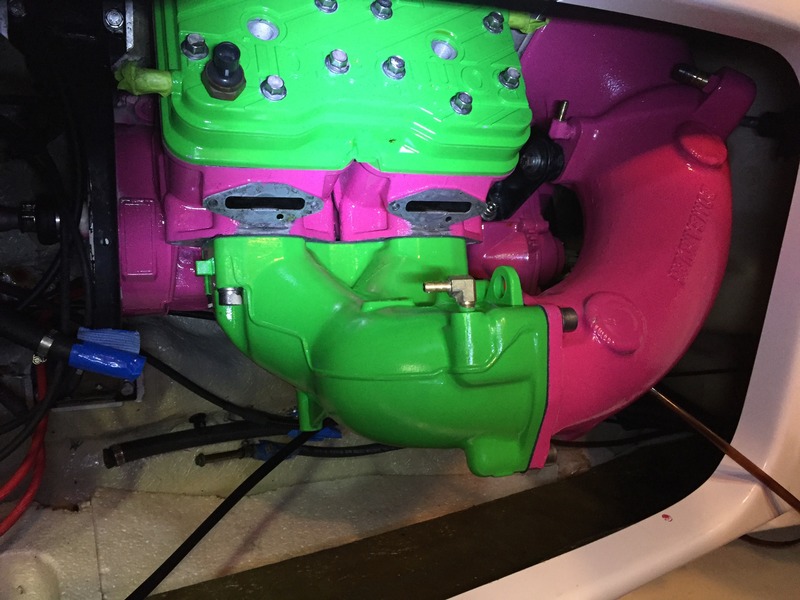

So I decided to make a build thread not only to document the work but to also be more efficient and have one common place to ask any/all questions or ask advice on task I come across. I have here a beautiful 97 gtx that we have owned since 97. It's in need of some TLC but I am hoping with some time and effort to get her running back like she did on day one. A little background on the ski

-Purchased brand new in 97 with 0 hours

-Original motor lasted until aprox 260-275 hours then the oil pump failed and the cylinder cracked

-Paid a shop nearly $2000 to install a new engine "sbt". Engine lasted aprox 10 hours and they said the rave valve broke & engine ate itself>huge loss of $$ here

Purchased a used oem engine with aprox 60 hours on it from a shop on this forum & installed the motor myself. I ran into issues with it after doing the installation myself. Long story short the carb settings were all sorts of wrong but it took 3 shops to find this problem and once I found a shop that knew what they were doing it was fixed in 30 minutes and ran great. Fast forward and I ended up winterizing the ski and putting it in storage for 2 years. I took it out this summer, replaced the battery, replaced the starter "was rusted and siezed" and it started and ran but I am having some issues.

Notes: I am running pre-mix after the oil pump incident. I don't find adding oil to the gas is an issue and I would prefer to just run-premix in the long run if I can get a few more summers out of this ski.

Known problems:

-12v low>this flashes nearly all of the time

-hard to start>sometimes the ski is hard to start>primarily leading this towards the 12v & having a bad rectifier so the battery is constantly dead

-idles low "900 rpm idle". Drives fine above 900rpm but it sounds a little ruff trying to idle that low and often dies giving gas if you drop the accelerator instead of easing into it off idle

-speed/mph dosnt work. It shows 0 mph all the time

-throttle cable broke. The plastic clip around the cable inside the handle lever broke

-studders sometimes around 4200 rpm or a hesitation at the least

-had a decent amount of water inside the ski after the last outing, could not determine if it was just from the amount of rain the ski was in while uncovered or if their is water getting in somewhere else

-floor mats are coming up

-cover is faded and torn. I patched what i could but its almost 20 years old, time for a new sea doo cover

-fuel gauge always shows empty

Now why fix her up? Well I dont owe and money on it, I am mechanically inclined and have the time now to fix it up. It ran great for a really long time when we first got it and I want to get her back up to par. When she runs its a blast to drive. After a good haul glaze back in the day the speedo would read 61-63 on a smooth evening. I dont want to put a ton of money into her but I feel I should be able to complete this project for $500 or less unless something mechnical/major were to come up.

I am not a mechanic and carbs were before my time so I will be doing lots of reading and asking questions

The plan parts wise:

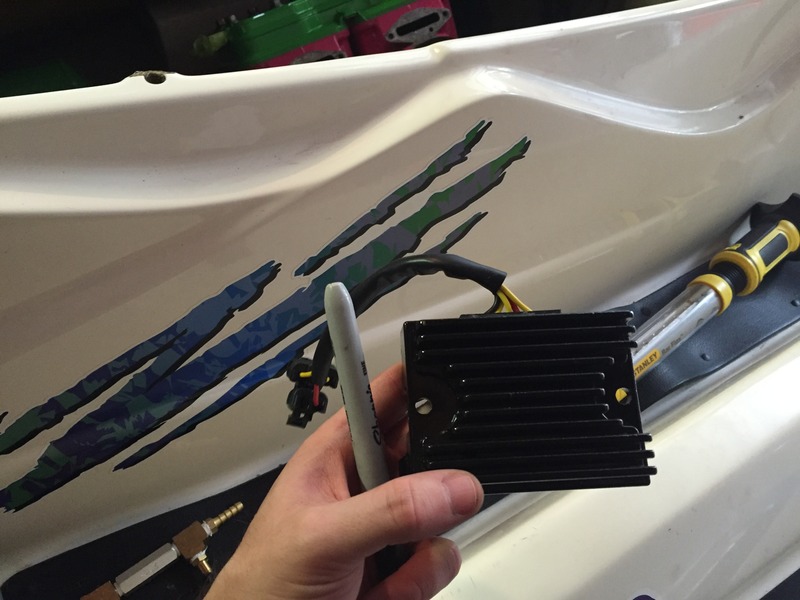

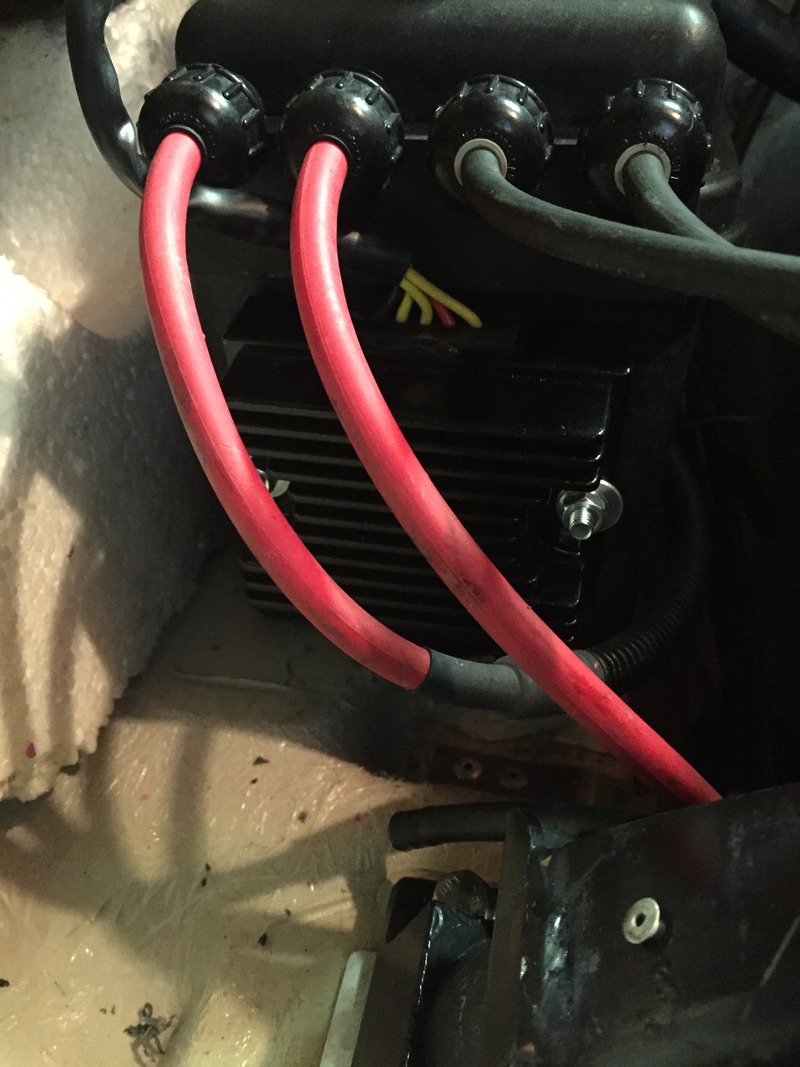

-replacement rectifier>purchased

-replacement speed wheel>purchased

-replacement throttle cable & lever>purchased

-replacement ski cover>searching

-replacement floor mats>searching & considering hydro turf in molded diamond black

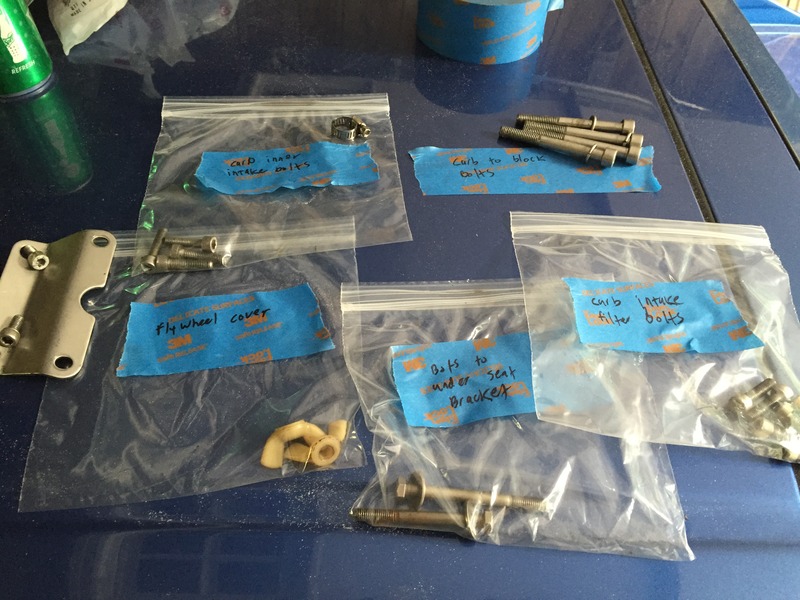

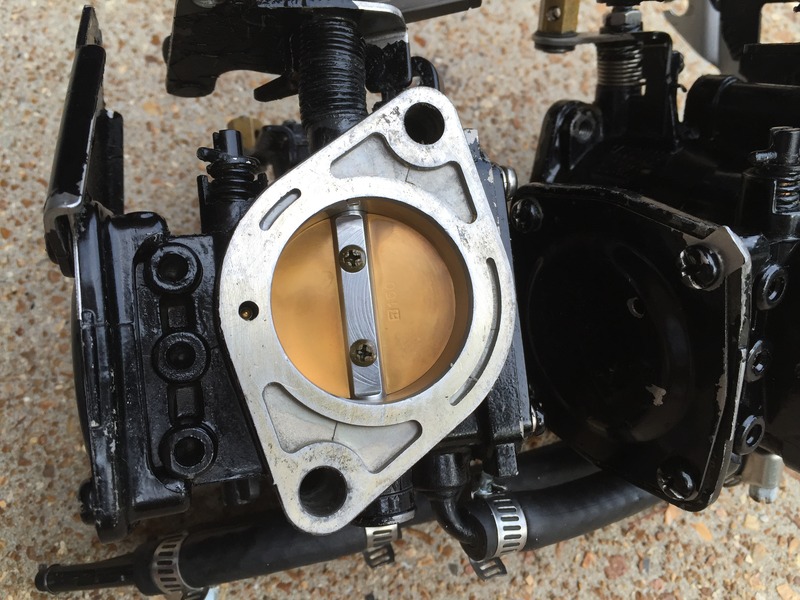

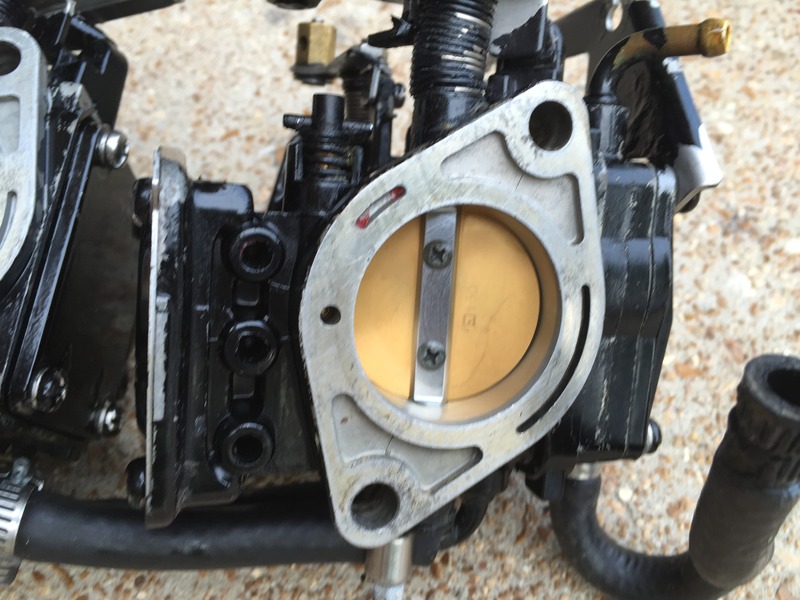

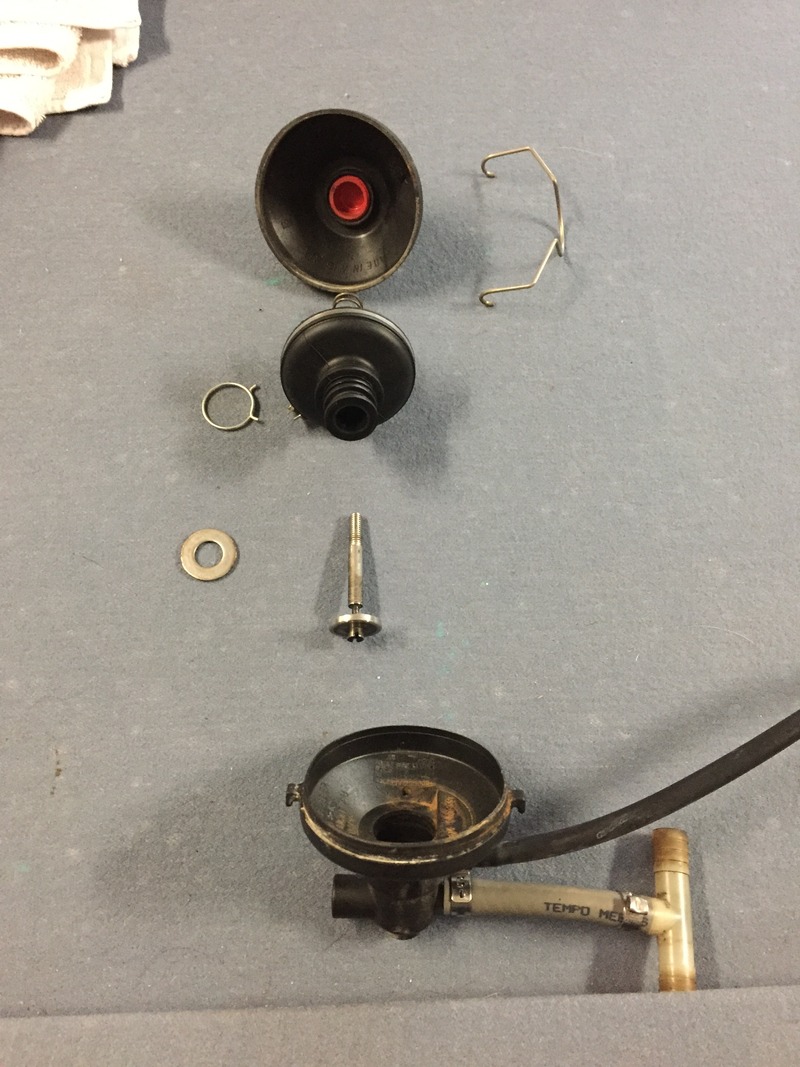

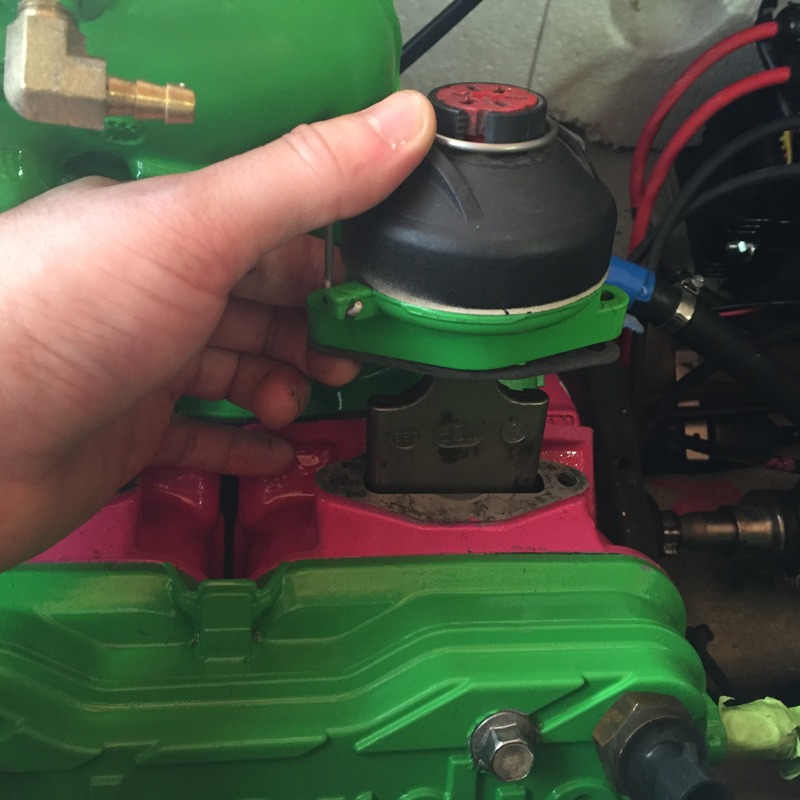

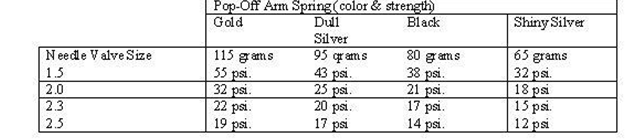

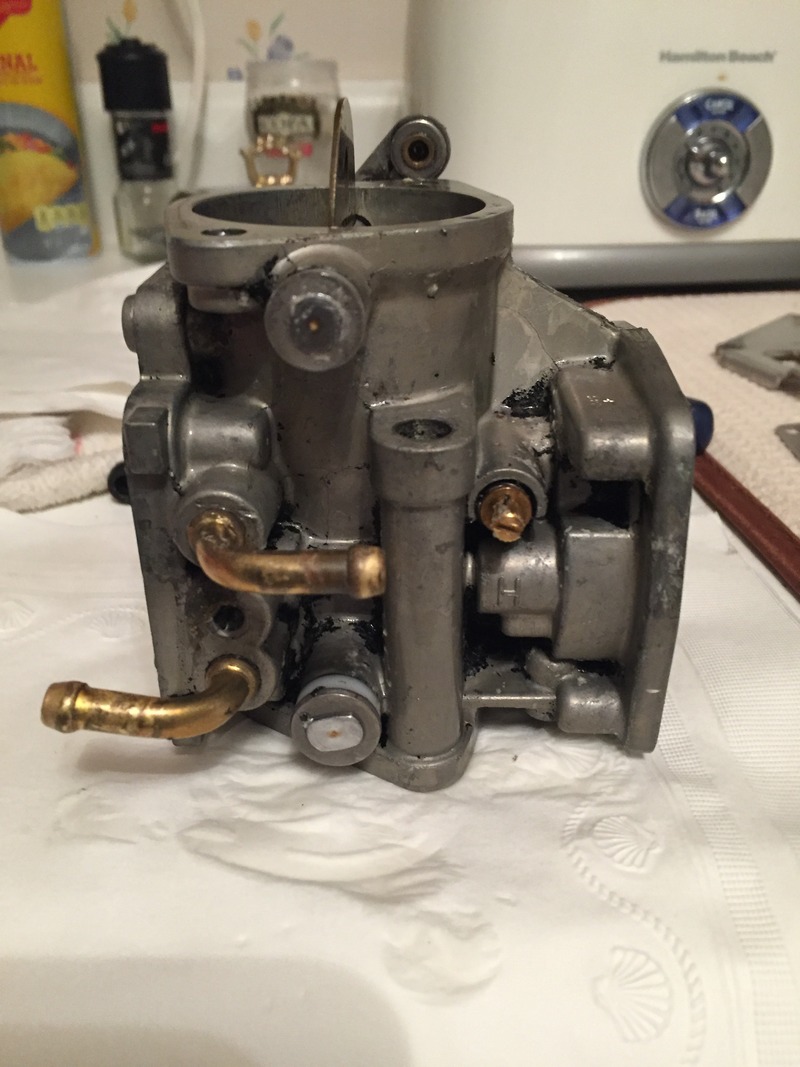

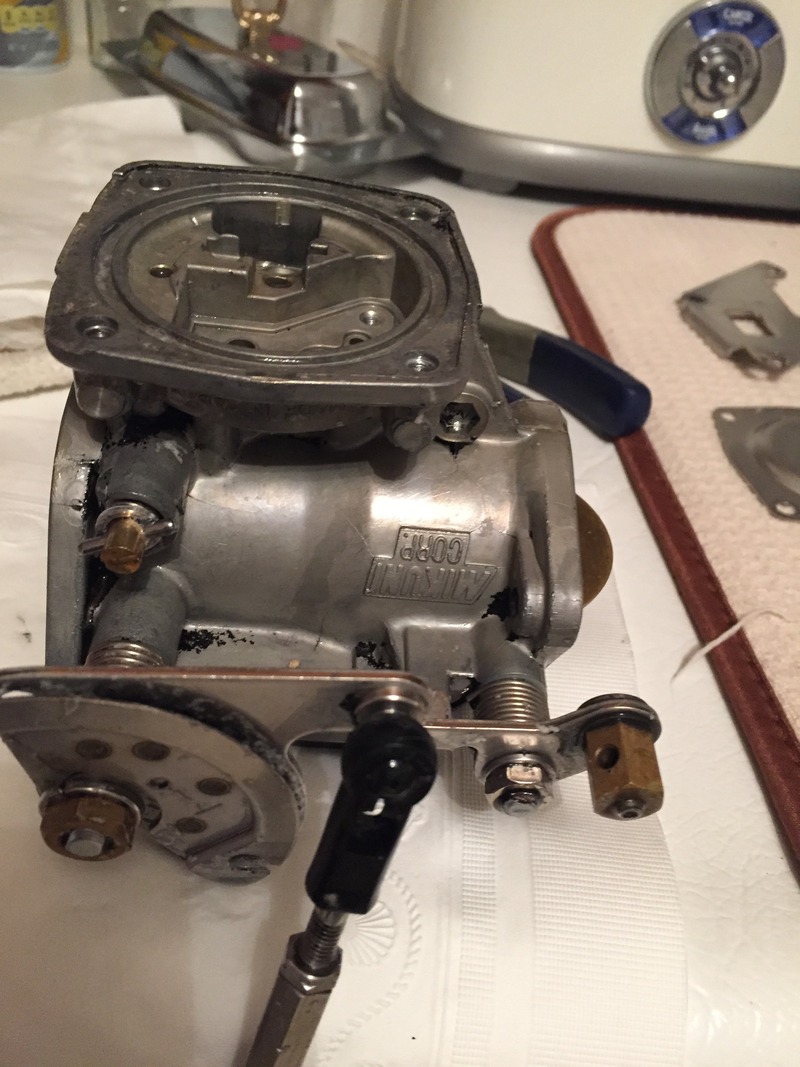

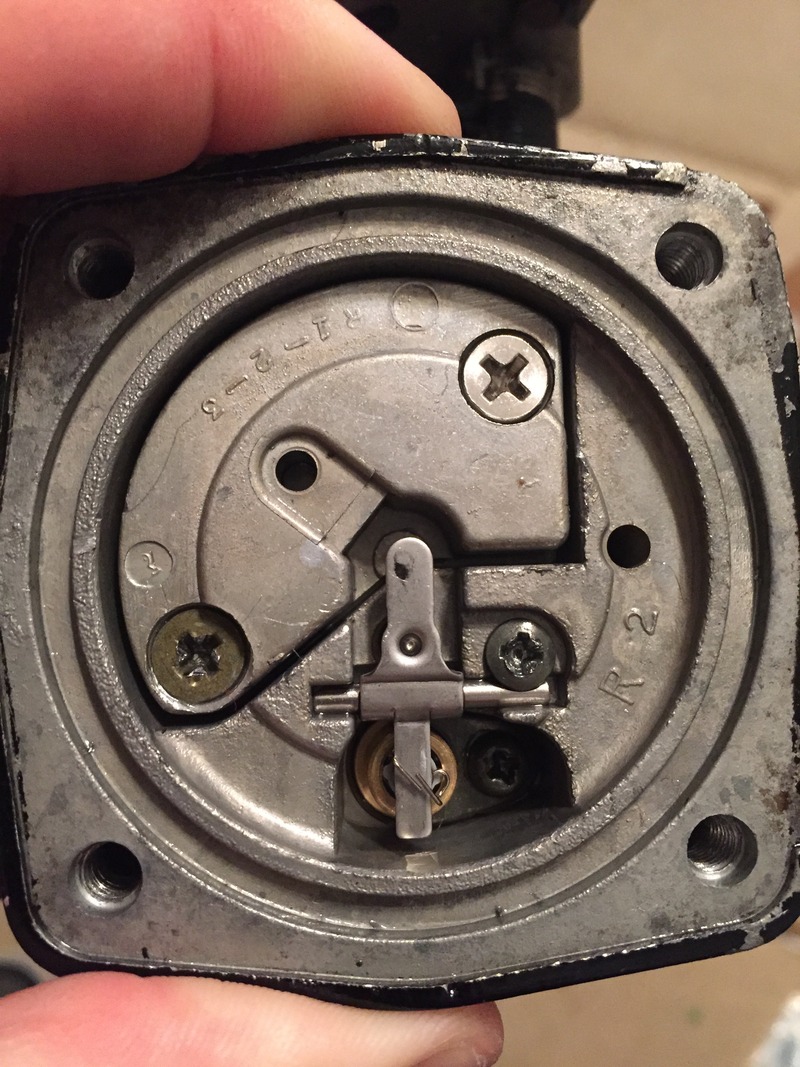

-pull/clean or possible rebuild carbs>also check all settings

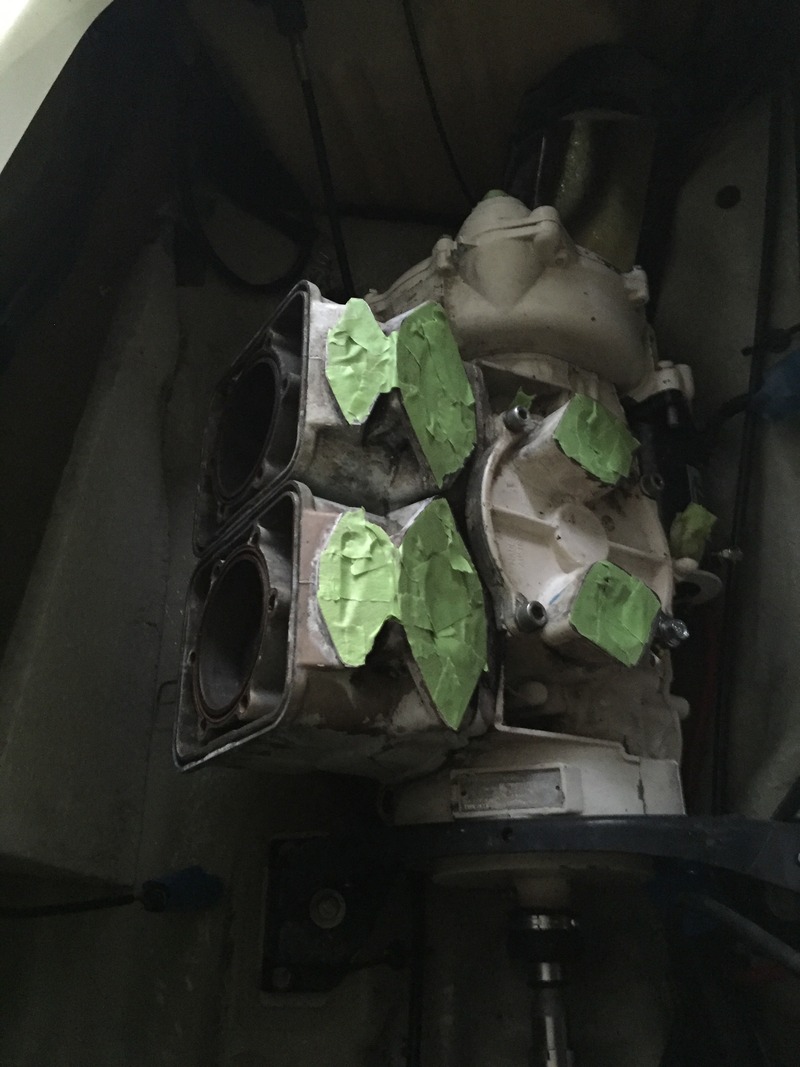

-pulled/clean or replace rave valves

-use wipe/new on all black trim "someone used the wrong type of soap on the ski and it turned all the black trim grey a while back"

-replace fuel float>purchased

Someone used the wrong type of soap and it ate the nice finish off all the plastic

Floor Mats are raised up everywhere. I am most likely going to replace with hydro turf mats.

-Purchased brand new in 97 with 0 hours

-Original motor lasted until aprox 260-275 hours then the oil pump failed and the cylinder cracked

-Paid a shop nearly $2000 to install a new engine "sbt". Engine lasted aprox 10 hours and they said the rave valve broke & engine ate itself>huge loss of $$ here

Purchased a used oem engine with aprox 60 hours on it from a shop on this forum & installed the motor myself. I ran into issues with it after doing the installation myself. Long story short the carb settings were all sorts of wrong but it took 3 shops to find this problem and once I found a shop that knew what they were doing it was fixed in 30 minutes and ran great. Fast forward and I ended up winterizing the ski and putting it in storage for 2 years. I took it out this summer, replaced the battery, replaced the starter "was rusted and siezed" and it started and ran but I am having some issues.

Notes: I am running pre-mix after the oil pump incident. I don't find adding oil to the gas is an issue and I would prefer to just run-premix in the long run if I can get a few more summers out of this ski.

Known problems:

-12v low>this flashes nearly all of the time

-hard to start>sometimes the ski is hard to start>primarily leading this towards the 12v & having a bad rectifier so the battery is constantly dead

-idles low "900 rpm idle". Drives fine above 900rpm but it sounds a little ruff trying to idle that low and often dies giving gas if you drop the accelerator instead of easing into it off idle

-speed/mph dosnt work. It shows 0 mph all the time

-throttle cable broke. The plastic clip around the cable inside the handle lever broke

-studders sometimes around 4200 rpm or a hesitation at the least

-had a decent amount of water inside the ski after the last outing, could not determine if it was just from the amount of rain the ski was in while uncovered or if their is water getting in somewhere else

-floor mats are coming up

-cover is faded and torn. I patched what i could but its almost 20 years old, time for a new sea doo cover

-fuel gauge always shows empty

Now why fix her up? Well I dont owe and money on it, I am mechanically inclined and have the time now to fix it up. It ran great for a really long time when we first got it and I want to get her back up to par. When she runs its a blast to drive. After a good haul glaze back in the day the speedo would read 61-63 on a smooth evening. I dont want to put a ton of money into her but I feel I should be able to complete this project for $500 or less unless something mechnical/major were to come up.

I am not a mechanic and carbs were before my time so I will be doing lots of reading and asking questions

The plan parts wise:

-replacement rectifier>purchased

-replacement speed wheel>purchased

-replacement throttle cable & lever>purchased

-replacement ski cover>searching

-replacement floor mats>searching & considering hydro turf in molded diamond black

-pull/clean or possible rebuild carbs>also check all settings

-pulled/clean or replace rave valves

-use wipe/new on all black trim "someone used the wrong type of soap on the ski and it turned all the black trim grey a while back"

-replace fuel float>purchased

Someone used the wrong type of soap and it ate the nice finish off all the plastic

Floor Mats are raised up everywhere. I am most likely going to replace with hydro turf mats.