acuratech481

New Member

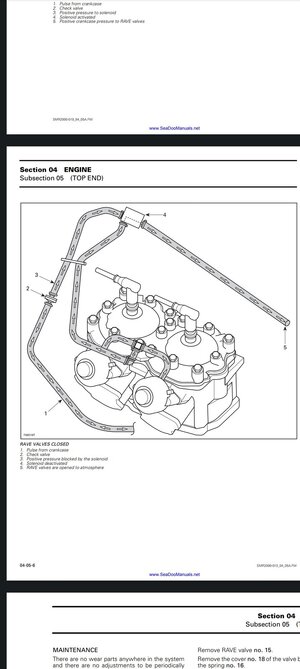

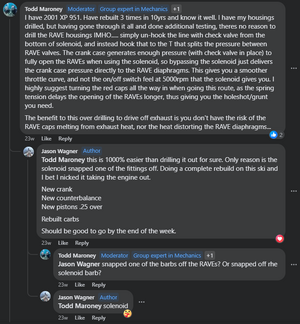

When drilling the RAVE valves on a 951 to make them mechanical and no longer rely on the electric solenoid, does anyone know what to do with the pulse hose from the crank case that goes to the solenoid?

Can the Solenoid be removed and left unplugged? Or will that causes fault codes?

Does the vent hose from the solenoid to the tunnel of the hull get cappped?

Do you cap the pulse hose at the fitting on the engine block?

So far, I've looped the RAVE valves together with a piece of hose.

This is the last piece to my puzzle so any input would be greatly appreciated!

Can the Solenoid be removed and left unplugged? Or will that causes fault codes?

Does the vent hose from the solenoid to the tunnel of the hull get cappped?

Do you cap the pulse hose at the fitting on the engine block?

So far, I've looped the RAVE valves together with a piece of hose.

This is the last piece to my puzzle so any input would be greatly appreciated!