Rosie2514

Active Member

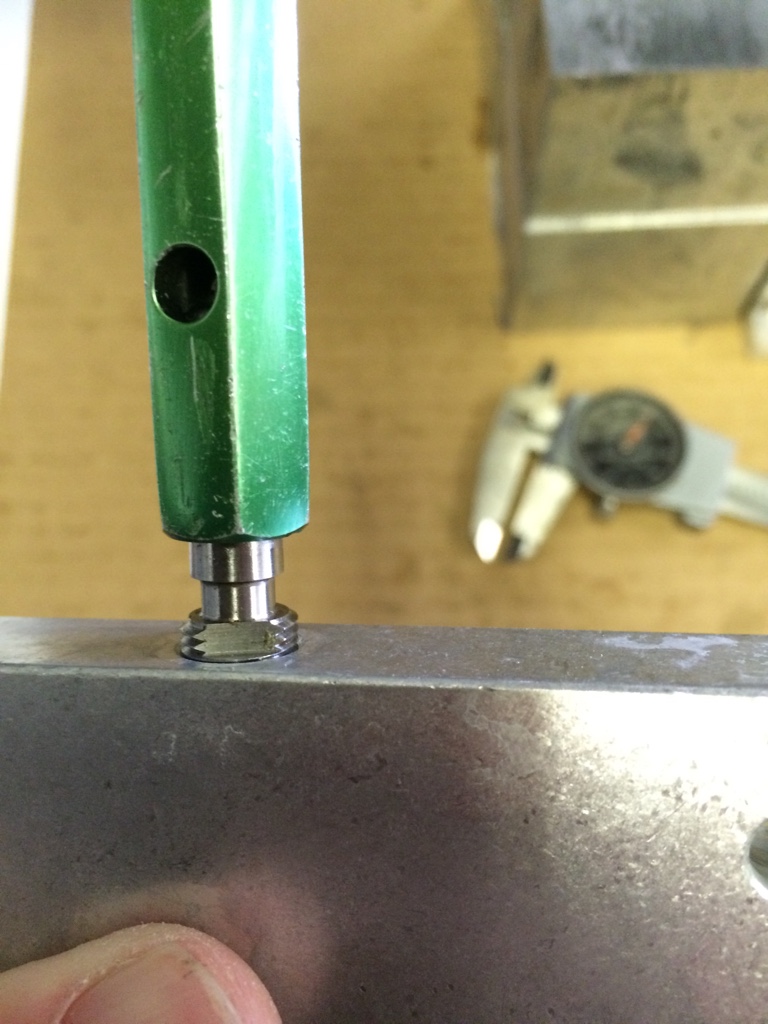

I noticed upon trying to install my temp sensor into my "new" buckshot head that it gets really tight after about 6 or 7 revolutions. It will not go down all the way flush like it did on the old head, and if it will it will be a VERY tight ordeal. What im wondering is if maybe somehow i could configure a TTO temperature sensor to use that same hole for an accurate live temp reading. Any thoughts?