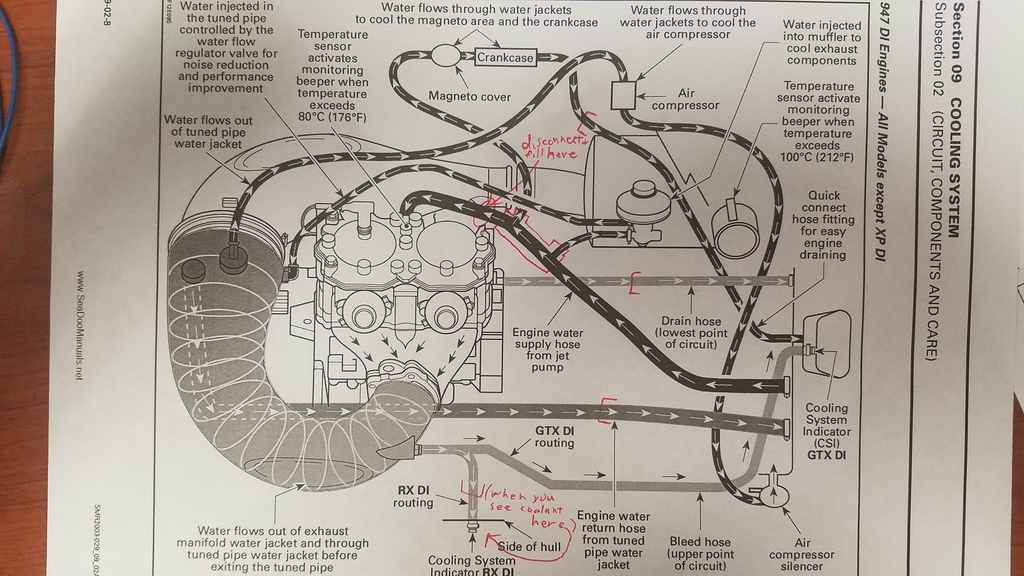

Hello all, First time PWC owner, picked up a pair of 03 RXDI's this spring and ran them about 3 times this summer in the Long Island Sound, always flushed with fresh water after running. Looking to winterize them and the manual is a little tricky so I was hoping I could get some clarification on a few things. Step 1 says check "engine drain hose" and make sure there is no sand in it and if there is, clear it. I assume this is the cylinder drain hose? I can't find a way to easily disconnect this line to flush it. Any ideas?

Both my rxdi's have sand in them and I remember them being that way when I purchased them. Since I didn't know what I was looking at when I bought them, I assumed it was a debris line of sorts. Never had any overheating issues though.

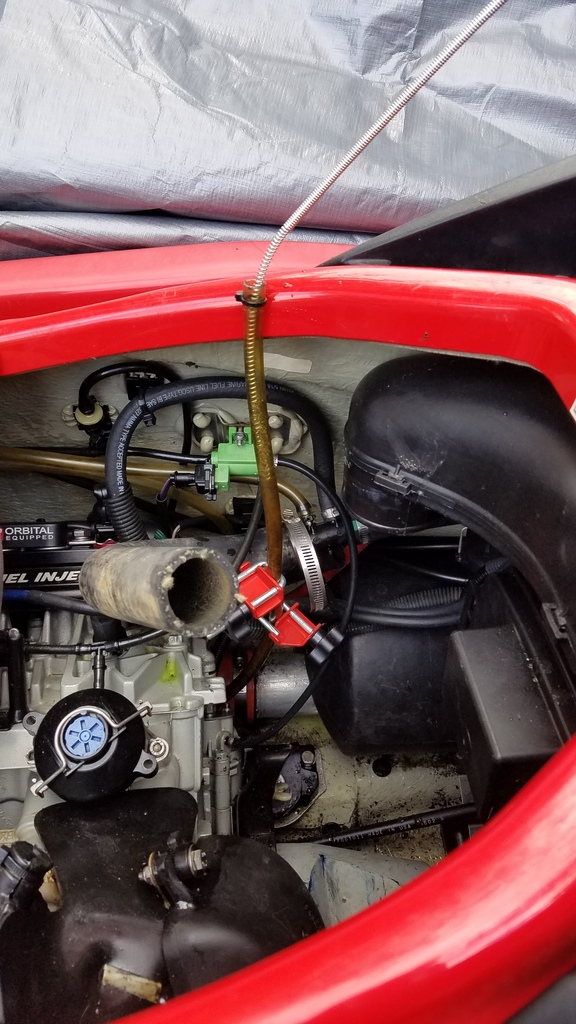

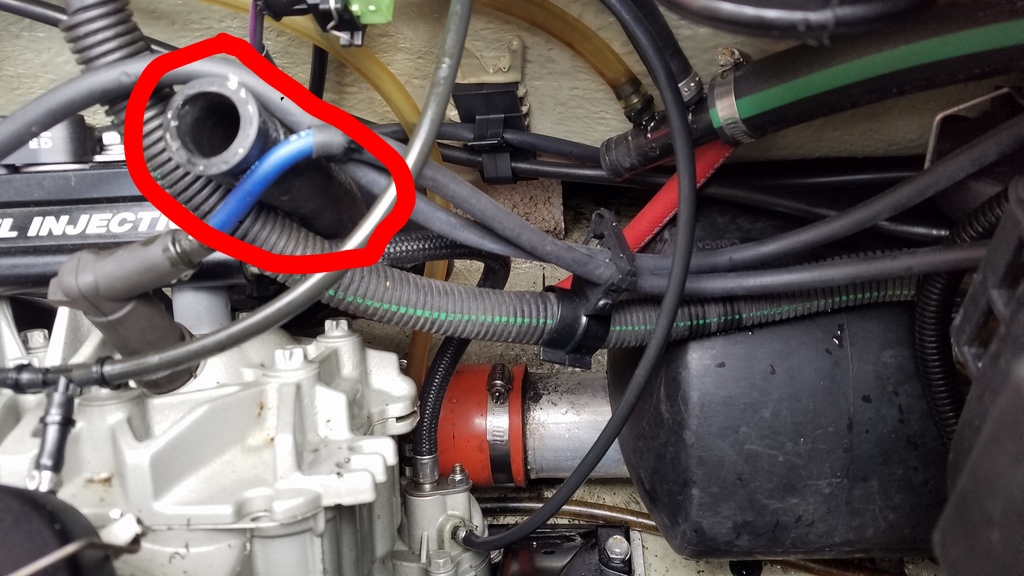

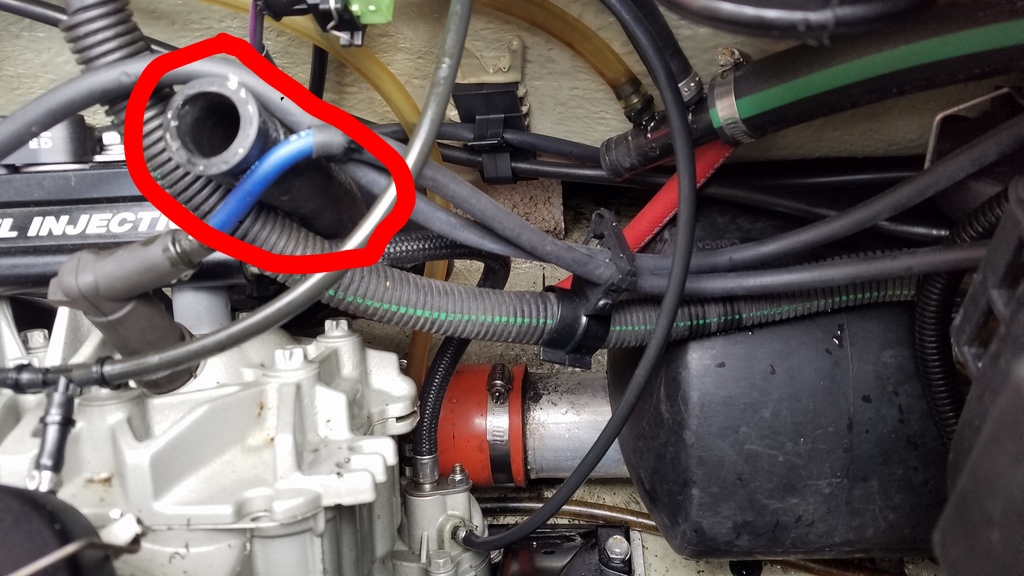

I tried to continue on, clamping the appropriate hoses, removing the inlet hose that goes to the engine at the T:

The owners manual states I should pour antifreeze into the inlet hose until I see antifreeze at the "cooling system bleed outlet" and then put a clamp on the "bleed outlet hose". I'm not sure where I should be looking to see antifreeze at the bleed outlet and the bleed outlet hose is a black opaque one.

I started to fill the inlet hose(which was full of water when I disconnected it) and it filled with antifreeze and spilled out, never saw it move through the system. The maintenance manual says I should be using a 1/2" id hose 3 feet in the air to create pressure. Is that what maybe went wrong?

Thanks in advance! Winter is coming!

Also...would pressurizing antifreeze through the flushing port work for winterizing my rxdi? I understand this is one of those personal questions where some people say stick to the manual and others say they do it this way all the time and never have problems. Looking for some cold weather personal experience!

Both my rxdi's have sand in them and I remember them being that way when I purchased them. Since I didn't know what I was looking at when I bought them, I assumed it was a debris line of sorts. Never had any overheating issues though.

I tried to continue on, clamping the appropriate hoses, removing the inlet hose that goes to the engine at the T:

The owners manual states I should pour antifreeze into the inlet hose until I see antifreeze at the "cooling system bleed outlet" and then put a clamp on the "bleed outlet hose". I'm not sure where I should be looking to see antifreeze at the bleed outlet and the bleed outlet hose is a black opaque one.

I started to fill the inlet hose(which was full of water when I disconnected it) and it filled with antifreeze and spilled out, never saw it move through the system. The maintenance manual says I should be using a 1/2" id hose 3 feet in the air to create pressure. Is that what maybe went wrong?

Thanks in advance! Winter is coming!

Also...would pressurizing antifreeze through the flushing port work for winterizing my rxdi? I understand this is one of those personal questions where some people say stick to the manual and others say they do it this way all the time and never have problems. Looking for some cold weather personal experience!

Last edited by a moderator: