Hello Folks,

Thanks for such a great, friendly, and intuitive Forum

I was suckered into buying a very good looking boat and since this was my first jet boat I didn't do my homework to check everything and believed the seller. He claimed everything works and it just needed a battery. I bought a battery and it doesn't turn at all.

I studied almost every thread about 1999 challenger and learned about the beeps on the key insert but mine doesn't even make any beep. I know the battery is good as the horn and bilge pump works when I turn on the switch.

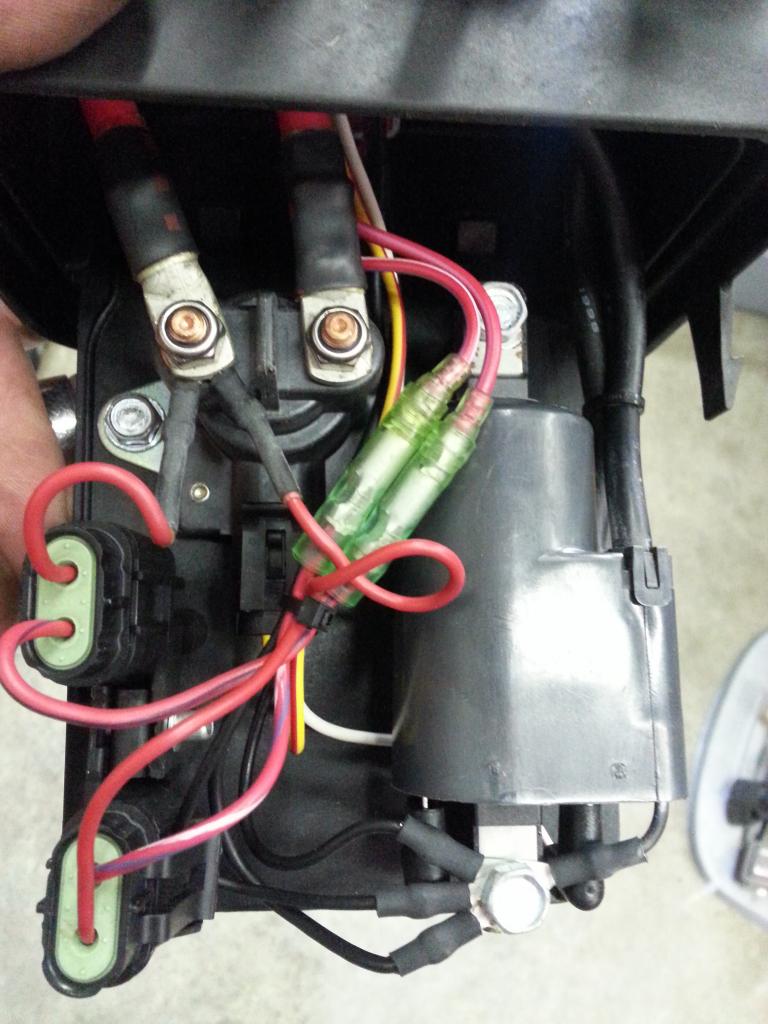

Please HELP me what must I do next? What can I check? I can post pictures if that'll help

Appreciate all the help

Thanks for such a great, friendly, and intuitive Forum

I was suckered into buying a very good looking boat and since this was my first jet boat I didn't do my homework to check everything and believed the seller. He claimed everything works and it just needed a battery. I bought a battery and it doesn't turn at all.

I studied almost every thread about 1999 challenger and learned about the beeps on the key insert but mine doesn't even make any beep. I know the battery is good as the horn and bilge pump works when I turn on the switch.

Please HELP me what must I do next? What can I check? I can post pictures if that'll help

Appreciate all the help