On that machine it goes battery to engine/stator, stator to mpem, mpem to rear ebox.

Your abnormality is the big question.

Pickup/trigger...just ohming it doesnt tell you it isnt broken. You really need to pull those two wires out of the big connector and put a volt meter on them and crank. You should see a little flutter in numbers, if not, the pickup bracket has broke.

BUT...the 97s should have the updated bracket so its unlikely its broken.

I physically inspected the stator cover and probed the sensor at the sensor. Bracket was in good shape without any debris around.

I HAVE NOT checked this resistance value at the MPEM wires, so possibly something could be shorting out or not making it to the MPEM.

What about turning the info center to RPM and trying to start the engine. If I see RPM in the info center then I know it is getting signal from the trigger coil. Seem legit?

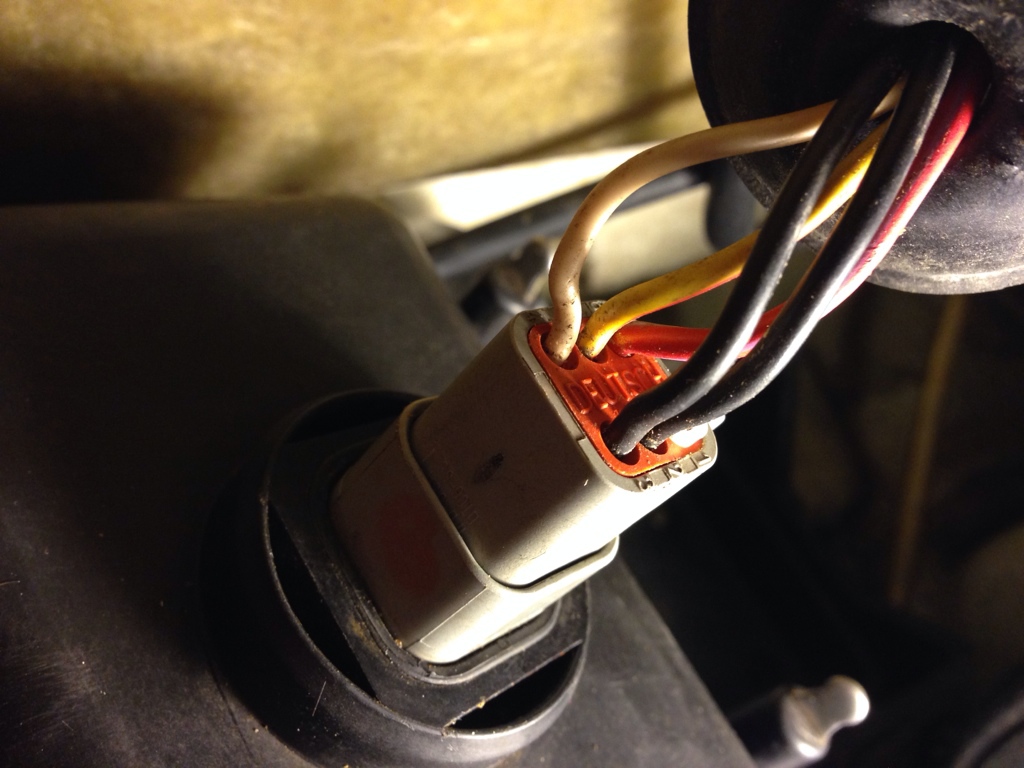

As for the abnormality, I have a theory. Take the wiring diagram out here. I am going to be making heavy reference to it.

Symptom: When the white wire is disconnected from the primary coil lead, the engine doesn't turn over.

Theory: The starting solenoid doesn't have a ground source to close the internal low current switch (that sends voltage to the starter)

Theory: The white wire is serving as ground for the solenoid when connected ( through the primary side of the coil)

Theory: The solenoid switch side normally gets its ground from the coil base ground lug, the base ground lug serves ground (or gets ground from?) the MPEM pin 3-17 or through VTS to MPEM through VTS ground pin 3-2.

**Note VTS is working** so it makes me think that VTS ground pin 3-2 is good.

Theory: The MPEM ground pin 3-24 is damaged/ bad connection between the stator housing and the MPEM.

Checklist:

Trigger coil checks

1. Check continuity between ground and wires on trigger coil (rule out a short of trigger coil)

2. Check resistance of trigger coil at MPEM plug (same as above)

3. Check RPM listed on gauge while starting engine (must have good pickup coil function to read RPM)

Grounding Checks

4. Check resistance at stator housing ground pin to battery neg terminal. (Ensure good ground for MPEM)

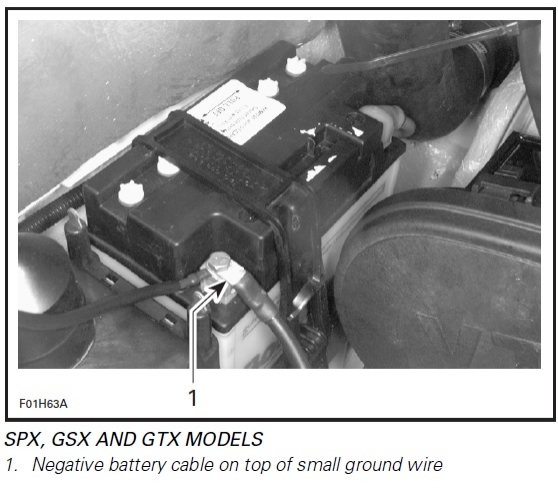

5. Assuming high resistance, relocate battery ground location to starter bolt (on rear engine mount cross brace now)

6. Check 3-24 (MPEM ground)

7. Check 3-17 (coil ground)

8. Check 3-2 (VTS ground, assuming OK now)

After tonight I hope to know if I have a grounding problem or a MPEM problem. What do yall think?