I just thought I would pass along the ammonia trick as some will say not to use a wire wheel. Don’t forget to update once you get it going.I was just measuring as I already had the top buttoned up. I know I wish I would have visually inspected that when I had it apart. And as for cleaning them up just used a wire wheel....

-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1996 Seadoo GTX 787 losing a cylinder? Cant find pressure leak!

- Thread starter Travisgg

- Start date

- Status

- Not open for further replies.

No, I don’t like that either, can’t really think what they are from? Also wanted to ask if you now have 1 piston that’s 3 sizes over and 1 that’s still factory. Is that ok to do?

Travisgg

Active Member

Yeah apparently two stroke it doesn't matter as it's not balanced.No, I don’t like that either, can’t really think what they are from? Also wanted to ask if you now have 1 piston that’s 3 sizes over and 1 that’s still factory. Is that ok to do?

Travisgg

Active Member

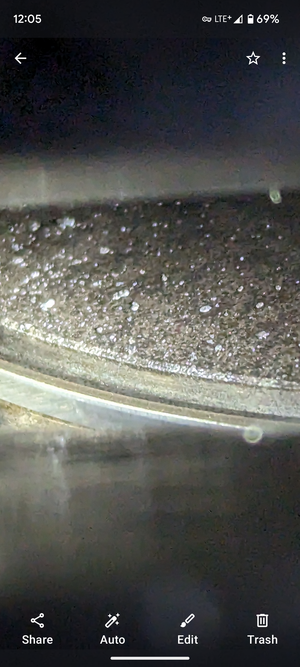

And what's going on with top of piston?Alright time to mock me here now boys...

This can't be just from 1 cylinder oversize though.... Opinions?

Attachments

Just a couple thoughts, did you end up doing the leak down test after putting in the new piston? The new piston you put in, was it a forged piston or cast? In snowmobiling the forged pistons will expand at a faster rate causing cold seizing if not heat cycled upon start up and require some additional piston to cylinder wall clearance. Did the motor run away at all upon startup? To me looks like an air leak, Also? Did you double check clearances before assembly? We will hopefully see what @mikidymac days later today. That’s to bad

Travisgg

Active Member

Leak down all good. Just cast WSM piston. Runs perfect no run away. Didn't double check clearances... The shop I had done at is pretty reputable but it was a Friday. I'm running 87 octane fuel.... I wonder if the oversize needs more octane and detonating?  @mikidymac will say told u lol. Also can't seem to feel the vertical scoring on the piston yet...more visual.

@mikidymac will say told u lol. Also can't seem to feel the vertical scoring on the piston yet...more visual.

Last edited:

Travisgg

Active Member

I think it's aluminum balls or something. I got to get better pictures but I don't think it was water it actually looks like metal pits or metal flakes...The white stuff on the piston is strange, water?

No need to change octane, 87 is perfect.

Travisgg

Active Member

I think it's aluminum balls or something. I got to get better pictures but I don't think it was water it actually looks like metal pits or metal flakes...

Attachments

You already know the answer.And I guess something was causing the scoring too so I really need to pull it all apart and measure don't I LOL.

Travisgg

Active Member

I hate my lifeYou already know the answer.

Travisgg

Active Member

I will make you proud and either resleeve it or bore the other one to match LOLI hate my life

Welcome to the Wild World of Watercraft.I hate my life

Travisgg

Active Member

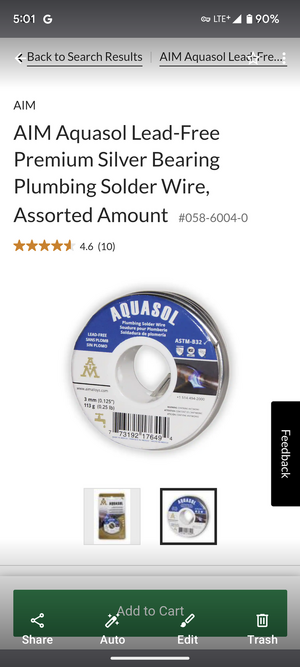

Will this work for squishy? Having a heck of a time finding rosin core solder..Welcome to the Wild World of Watercraft.

Attachments

Travisgg

Active Member

K ill keep looking. I'm assuming two and a half to 3 mm would be best in thickness rightThat solder tends to be pretty hard.

Rosin core solder is typically for electrical work.

JC-SUPERJET

Active Member

"ASH TRASH

This piston crown has an ash color, which shows that the engine has run hot. The ash color is

actually piston material that has started to flash (melt) and turned to tiny flakes. If this engine

was run any longer, it probably would,ve developed a hot spot and hole near the exhaust side

and failed. The main causes of this problem are too lean carb jetting, too hot spark plug range,

too far advanced ignition timing, too much compression for the fuel's octane, or a general

overheating problem."

Also, were the Ports Chamfered after the Boring? Does the Shop specialize in Two Stroke Cylinder work or are they mainly a 4 Stroke Shop?

Port edges need to have a Bevel for smooth transition/travel of the Rings.

Too many Shops forget to Chamfer the Ports on Two Stroke Cylinders...

This piston crown has an ash color, which shows that the engine has run hot. The ash color is

actually piston material that has started to flash (melt) and turned to tiny flakes. If this engine

was run any longer, it probably would,ve developed a hot spot and hole near the exhaust side

and failed. The main causes of this problem are too lean carb jetting, too hot spark plug range,

too far advanced ignition timing, too much compression for the fuel's octane, or a general

overheating problem."

Also, were the Ports Chamfered after the Boring? Does the Shop specialize in Two Stroke Cylinder work or are they mainly a 4 Stroke Shop?

Port edges need to have a Bevel for smooth transition/travel of the Rings.

Too many Shops forget to Chamfer the Ports on Two Stroke Cylinders...

Hey JC, just trying to pick your brain. To lean of carb jetting, to fix that do you just change the jets or one of the jets? Or when you say lean carb jetting, can that be fixed by adjusting either the low or high speed screw? Would this carb jetting have been thrown out of whack by the oversized piston? Or just wear. I’m assuming the size of the jet determines how much fuel is used? Just trying to learn something today, sorry for using your thread Travis to do it"ASH TRASH

This piston crown has an ash color, which shows that the engine has run hot. The ash color is

actually piston material that has started to flash (melt) and turned to tiny flakes. If this engine

was run any longer, it probably would,ve developed a hot spot and hole near the exhaust side

and failed. The main causes of this problem are too lean carb jetting, too hot spark plug range,

too far advanced ignition timing, too much compression for the fuel's octane, or a general

overheating problem."

View attachment 62537

Also, were the Ports Chamfered after the Boring? Does the Shop specialize in Two Stroke Cylinder work or are they mainly a 4 Stroke Shop?

Port edges need to have a Bevel for smooth transition/travel of the Rings.

Too many Shops forget to Chamfer the Ports on Two Stroke Cylinders...

JC-SUPERJET

Active Member

For a Stock Engine, the Seadoo Carb Jetting and Adjustment Specs are perfect provided the Fuel System and Carbs are clean, Genuine Mikuni Kits were used and there are no Air Leaks.

An Engine can run Lean due to an Air Leak even with perfectly Jetted and Tuned Carbs. That's why an Air Leak--down Test is critical.

Yes, bigger Jets flow more Fuel because they have bigger Holes.

For a Modified Engine, then probably,a new combination of Jets and Screw adjustments, even Needle and Spring, typically will be required. See Mikuni Manual for finding correct Jets, Pop-Off and Fine Tuning. The Mikuni Manual is your Bible. Put a Plastic Protective Cover over it because you are going to wear it out.

The Oversized Piston will typically not require a Jetting or Adjustment change. Ambient Air Temperature affects Fuel requirements in a Stock Engine/Ski. In which case, with the aid of a Tachometer, the Low and High Adjustments Screws can be adjusted (but is not required). But the High Speed Screw which is set at Zero turns in Seadoos, can only add fuel to the high speed circuit. So in the Hot Summer, when Air is less dense, the Engine will run a tad rich. Seadoo does this to prevent Lean Seizures from high speed adjustment mistakes. Fool proof. Halfway anyway

Most will never adjust for Air Temperature and that's fine. Only a slight loss of performance results from extreme hot weather.

Personally I like to fine tune my Yamaha Standup Bouy Course Racer for every consistent 10 degrees of Air temperature change. Because I notice the throttle response difference. At a 20 degree difference, the change in response is definitely noticeable. At 30 degrees, you can even hear a different Exhaust tone...

An Engine can run Lean due to an Air Leak even with perfectly Jetted and Tuned Carbs. That's why an Air Leak--down Test is critical.

Yes, bigger Jets flow more Fuel because they have bigger Holes.

For a Modified Engine, then probably,a new combination of Jets and Screw adjustments, even Needle and Spring, typically will be required. See Mikuni Manual for finding correct Jets, Pop-Off and Fine Tuning. The Mikuni Manual is your Bible. Put a Plastic Protective Cover over it because you are going to wear it out.

The Oversized Piston will typically not require a Jetting or Adjustment change. Ambient Air Temperature affects Fuel requirements in a Stock Engine/Ski. In which case, with the aid of a Tachometer, the Low and High Adjustments Screws can be adjusted (but is not required). But the High Speed Screw which is set at Zero turns in Seadoos, can only add fuel to the high speed circuit. So in the Hot Summer, when Air is less dense, the Engine will run a tad rich. Seadoo does this to prevent Lean Seizures from high speed adjustment mistakes. Fool proof. Halfway anyway

Most will never adjust for Air Temperature and that's fine. Only a slight loss of performance results from extreme hot weather.

Personally I like to fine tune my Yamaha Standup Bouy Course Racer for every consistent 10 degrees of Air temperature change. Because I notice the throttle response difference. At a 20 degree difference, the change in response is definitely noticeable. At 30 degrees, you can even hear a different Exhaust tone...

Thank you very much JC, I read through your reply but I will need to read through it again. It’s one thing to change this and that, for example do a carb rebuild with Mikuni parts but i really like to know exactly how things work if I can. It’s a lot to digest when you really get into the inner workings of things. Fortunately pretty much any project I have doesn’t require an in depth understanding of the carb workings, I just put back to stock. I knew there was something going on with air temperature as I always found my GSXR 750 would perform better on a cooler crisp morning with little humidity. Anyways, thank you for taking the time to post that

- Status

- Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 493

- Replies

- 1

- Views

- 491

- Replies

- 12

- Views

- 810

- Replies

- 16

- Views

- 789