When I was leak testing my 717 it wasn’t holding pressure, I tried vacuum and it held. In my case I didn’t have the bolts from the tuned pipe to the exhaust manifold torque properly, I was just about to order new oil seals and decided to re check my block offs. Maybe it would be worth double checking?

-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1996 Seadoo GTX 787 losing a cylinder? Cant find pressure leak!

- Thread starter Travisgg

- Start date

- Status

- Not open for further replies.

Travisgg

Active Member

Got it. So pressurize into the RV cavity and block or ballon the out vent and see the results right.

As for the block offs I RTv'd them all a few days ago and let it set up it was so annoyed trying to make sure it wasn't that causing the problem lol. That's so pretty sure they're all tight and sealed. Plus I was soaping them all looking for bubbles as well...

As for the block offs I RTv'd them all a few days ago and let it set up it was so annoyed trying to make sure it wasn't that causing the problem lol. That's so pretty sure they're all tight and sealed. Plus I was soaping them all looking for bubbles as well...

No, if your going to add your pressure through the oil line to the RV then block the RV return line on the back. If your going to pressurize through the pulse nipple then you could put ballons over the nipples of the RV cavity, kind of t he dame idea Mikidymac had of using soap over them to see if air is leaking past 2 of those center oil seals that separate the RV from the rest of the crankcase.

Travisgg

Active Member

@burtshaver2021 Going to find out tonight!!

Right on@burtshaver2021 Going to find out tonight!!View attachment 63016

Travisgg

Active Member

Balloons definitely puffed up a little bit after pressurizing top end. Still losing about 4 psi over 5 minutes. I put those caps on the rotary nipples with worm clamps ( after the balloon test) and kept bring pressure up to 8psi as it was dropping... in case the RV cavity was taking some of the air pressure.

Balloons definitely puffed up a little bit after pressurizing top end. Still losing about 4 psi over 5 minutes. I put those caps on the rotary nipples with worm clamps ( after the balloon test) and kept bring pressure up to 8psi as it was dropping... in case the RV cavity was taking some of the air pressure.Keeps losing pressure about the same rate though. So I guess I'm pulling motor to really give it a look over ? Or pressurize RV first by itself just to be sure?

@burtshaver2021

Last edited:

Sounds like your losing pressure through the inner oil seals to the RV cavity for sure, ballons are taking some air. It would be nice if there was a way to know if there was equal pressure in the RV and the rest of the engine. I guess you could just keep bringing the pressure up to 5 pounds or 8 pounds whichever you prefer although I think you already did that. It does sound like you have another leak most likely through the end seals or crankcase mating surfaces. I noticed you didn’t block off the rave valves, the manual says to block them but Mikidymac said you didn’t have to correct? You’ve sprayed all around though with soap though. Want to be sure first but sounds like your going to have to pull the motor

Travisgg

Active Member

Yeah I'll give it one last spray down when I have some patience again for it. It's just so odd because this was a crate motor right from BRP about 3 years ago. Previous owner burned a cylinder probably from fueling issue. You think it would be nice and tight but I guess I just have to treat it like an old motor and troubleshoot it. Maybe previous owner dropped the whole motor and cracked something on the install LOL. Who knows.Sounds like your losing pressure through the inner oil seals to the RV cavity for sure, ballons are taking some air. It would be nice if there was a way to know if there was equal pressure in the RV and the rest of the engine. I guess you could just keep bringing the pressure up to 5 pounds or 8 pounds whichever you prefer although I think you already did that. It does sound like you have another leak most likely through the end seals or crankcase mating surfaces. I noticed you didn’t block off the rave valves, the manual says to block them but Mikidymac said you didn’t have to correct? You’ve sprayed all around though with soap though. Want to be sure first but sounds like your going to have to pull the motor

Travisgg

Active Member

@burtshaver2021 so I'll test the RV cavity pressure on its own tonight or tomorrow. You probably already said this in one way or another but just to recap if that RV cavity doesn't drop pressure then I'm definitely leaking out a crank seal or case half somewhere right?

Yes

I’m hoping it’s the case that’s not sealed

That’s right, the Center seals are good

Travisgg

Active Member

So if i pull pump amd that pto circle thing (i have tool i think) will i see crank seal?That’s right, the Center seals are good

I would think so but not 100 percent sure, I’ve only changed oil seals on ski Doo revs

Travisgg

Active Member

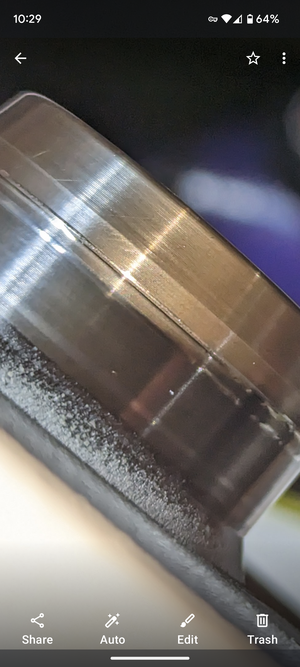

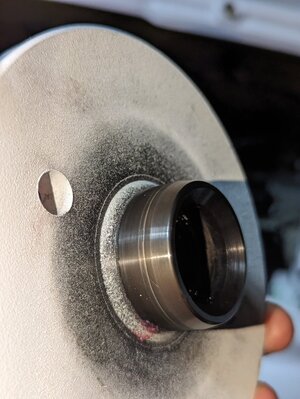

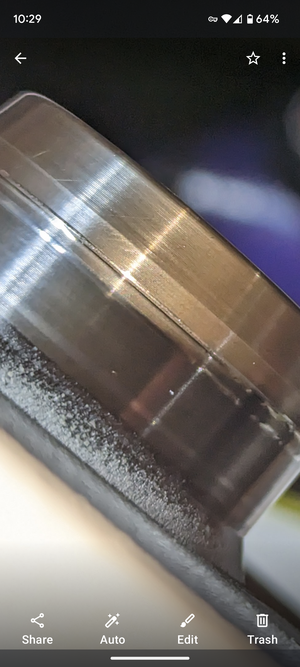

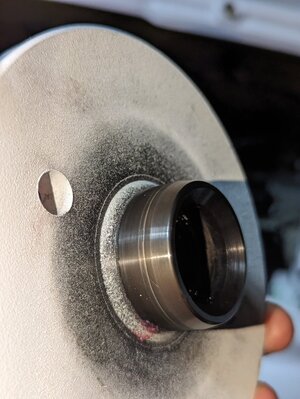

How do I know if this seal has an issue? Does the PTO flywheel normally have a little grove like this? I can feel the groove...

I think I need to put that PTO back on snug, pull the engine, and start spraying again with soapy water right? That way I can get a proper 360 view of the engine... It's just really hard to see that crank seal for soapy bubbles when the PTO is on there. Any tricks?

I think I need to put that PTO back on snug, pull the engine, and start spraying again with soapy water right? That way I can get a proper 360 view of the engine... It's just really hard to see that crank seal for soapy bubbles when the PTO is on there. Any tricks?

Last edited:

Travisgg

Active Member

All right doing some more bubble testing on the crank seal. The challenge is it's hard to see the crank seal once you put the PTO on. So I threaded the PTO 3/4 of the way in where it seemed like it had a good seal plus I could still see a tiny bit of the crank seal. Sprayed it and I've got just a tiny bit of bubbles coming out. Is my method accurate if that PTO is seated in there three quarters of the way versus all of the way... seems to be holding air the same regardless if all the way or three quarters of the way in terms of the leak down. If that's the case I guess I've got a bad seal for some reason. Remember this was a crate motor from BRP about 3 years ago with maybe 20-30 hours on it... Maybe previous owner damaged seal or something I don't know.

Last edited:

Travisgg

Active Member

All right had an interesting talk with a two-stroke Ninja. He said it's not completely unheard of for a seal to dry out especially if it was old stock. So that motor could have been sitting in a BRP warehouse for 10 years when previous owner bought it. So I'm going to replace crank seals and pressure test. Do I need to worry about that groove on the PTO @mikidymac @burtshaver2021 or just put the new seal in and it should line up fine? Ordering some wsm seals if that's fine.

Travisgg

Active Member

Hey guys sorry to bug again. Crankshaft seals going in this weekend... Do I need to do anything with that groove on PTO shaft or just put back with new seals and go.. @mikidymac

Travisgg

Active Member

Alright here's the latest. Can't find pressure leak anywhere! Tell me you opinion what you think i should do... Still replace crank seals? @mikidymac

That picture shows damage from last piston.

That picture shows damage from last piston.

Attachments

Last edited:

Travisgg

Active Member

How you making out Travman?

Travisgg

Active Member

Getting there! Found some pressure leaking out of the crank bolts on the bottom! Unbelievable. I backed them out and put some loctite under the heads to see if that sealed it up tight and that seem to do the trick... Then I ended up splitting the case because obviously there was some sealing issues between the halves if it was leaking out of those bolts. So just need to seal back together sometime this week. You like to put anything on the crank seals, inner seals, balancer seal, like just a tiny smear of anaerobic or just dry?

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 586

- Replies

- 2

- Views

- 274

- Replies

- 1

- Views

- 552

- Replies

- 12

- Views

- 996