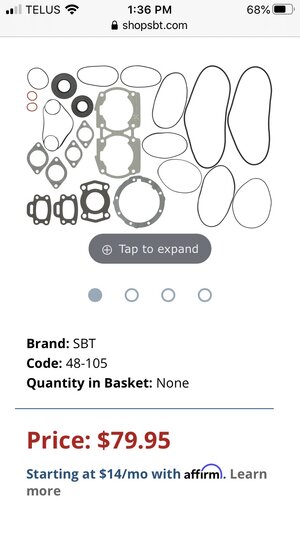

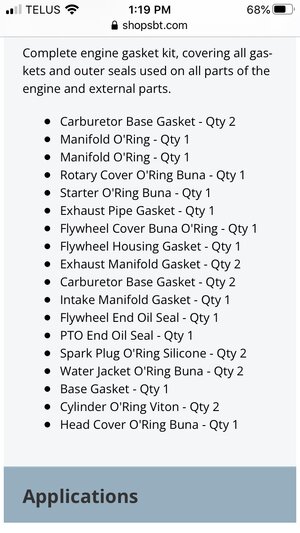

View attachment 61350I took the cylinder cover off just to see the condition of the o rings and maybe the reason I’m not able to pressurize the cooling system, I had winterized the engine with biodegradable antifreeze when I purchased it, I also took the plugs out and fogged the cylinders. Cylinder bores look ok which makes sense as compression was good too. I picked out the inner o ring from the top of the cylinder and it felt a little rough. Also notice irregular carbon deposits on the top of the pistons? Not sure what this means? I know the machine was running some horride green oil so probably not burning to clean due to improper oil? I’ve seen the difference proper oil makes for carbon deposits and it’s substantial. A fair bit of sediment and rust in the cooling jackets, not sure if that’s an issue or not? I mean they do run an open loop cooling system. I think I Should clean up where the o rings go and order new ones at a minimum especially after taking the one out, it’s not going back in properly and it has a rough texture In spots. What’s a good way to clean up the female threads in the cylinders? Just carb cleaner, brass or nylon bottle brush and some compressed air with the bores blocked off with rags?