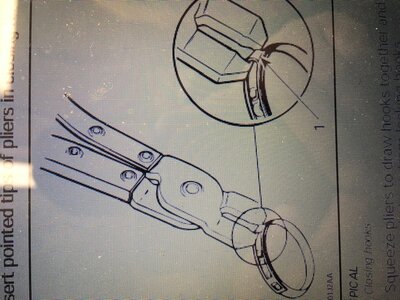

Hello everyone, spring has came early here in Ontario so my attention has turned back to my seadoo’s. I have a 1995 HX that I purchased in 2021 on a double galvanized trailer, a non running 1992 XP and a parts 92 XP were included for 1800.00 total. I’ve been looking forward to getting it running since I bought it, should be a lot of fun to drive. I’m not looking to do a total restoration at this point just what needs to be done to get it on the water running without doing any damage to it. My experience is almost non existent, but I should be able to muddle through with some help from the people on this forum. So far I’ve taken it to the local dealership and had a new dess key programmed for it, started changing the tempo fuel lines, I’ve Had it running for about 15 seconds with mixed fuel down the carbs, taken a compression test, I believe it was roughly 140 pounds per cylinder. I plan on removing the old fuel from the gas tank, removing old oil and replacing it with xps, I will be following Mikidymac’s thread to rebuild the carburetors. I could be awhile as I have some other projects coming up that have to be done like renovating our rental house and have a roof coming up as well but I will see this through. I have looked quickly at the manual but haven’t looked at any utube video’s, first question is, what is the best way to remove the carburetors from the intake manifold? Mainly what is the best way to detach the throttle and choke cable? And the throttle cable is connected to the 2 carburetors with the adjusting bolt, this adjuster has a ball joint on each end, can I pop this joint apart? Do I simply press it apart? I would like to take them off without disturbing the set up of the carburetors if it’s possible as I am worried about being able to set them up properly after cleaning.