Hi:

I would like to tap into everyone's collective wisdom on repairing a 1994 Sea Doo GTX.

Background

Last week, I pulled a non running 1994 Model Sea Doo GTX (Model 5862) out of a relative's barn. The placard on the engine reads Type 657. It was last in the water before 2015, and has been sitting in the barn awaiting disposal for at least five years. It was a fresh water PWC, and the hull seems to be in good condition. The bilge does have some oil in it.

I found a note to the mechanic that read "oil on water after boat" and "loss of power." If I am getting the story correct, the mechanic told my relatives that it needed a new motor, and it was not worth rebuilding.

When I rolled it out, my son wanted it pressure washed immediately. He wants to see it run again, and told his friends that we were going to fix it. (ARRRGH!, I am feeling some pressure now.)

I just downloaded the manual. I have basic mechanic's tools and access to lifts, etc. I have very basic mechanical skills. (Changing fuel injectors, water pumps, etc. on automobiles.)

What I have done so far:

I put a battery on it, and the starter will turn the engine.

I tested the compression with an old, finger-tightened, Sears compression tester. The forward (Mag?) cylinder was at 100 psi and the aft cylinder (pump?) was at 80 psi.

I gave it a shot of ether, and it fired. I assume that the gas is bad, and the fuel lines and carburetor are gunked up.

Repair list, so far:

From reading this forum, my to do list so far is:

Clean the fuel tank.

Replace the fuel lines.

Replace the fuel selector.

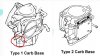

Rebuild the carburetor with genuine Mikuni kits.

Replace the oil lines.

Questions:

Some of these questions fall into the category of is it worth it and the others are how do I do it. My questions are:

1. What should I look for when evaluating it for repair? Is there a checklist somewhere?

2. Is it worth rebuilding?

3. What is the estimated value as it sits now?

4. What would the estimated value be running?

5. What else needs to be done?

6. Any other words of wisdom that you do not mind sharing?

I appreciate everyone's time.

Thanks,

nT

I would like to tap into everyone's collective wisdom on repairing a 1994 Sea Doo GTX.

Background

Last week, I pulled a non running 1994 Model Sea Doo GTX (Model 5862) out of a relative's barn. The placard on the engine reads Type 657. It was last in the water before 2015, and has been sitting in the barn awaiting disposal for at least five years. It was a fresh water PWC, and the hull seems to be in good condition. The bilge does have some oil in it.

I found a note to the mechanic that read "oil on water after boat" and "loss of power." If I am getting the story correct, the mechanic told my relatives that it needed a new motor, and it was not worth rebuilding.

When I rolled it out, my son wanted it pressure washed immediately. He wants to see it run again, and told his friends that we were going to fix it. (ARRRGH!, I am feeling some pressure now.)

I just downloaded the manual. I have basic mechanic's tools and access to lifts, etc. I have very basic mechanical skills. (Changing fuel injectors, water pumps, etc. on automobiles.)

What I have done so far:

I put a battery on it, and the starter will turn the engine.

I tested the compression with an old, finger-tightened, Sears compression tester. The forward (Mag?) cylinder was at 100 psi and the aft cylinder (pump?) was at 80 psi.

I gave it a shot of ether, and it fired. I assume that the gas is bad, and the fuel lines and carburetor are gunked up.

Repair list, so far:

From reading this forum, my to do list so far is:

Clean the fuel tank.

Replace the fuel lines.

Replace the fuel selector.

Rebuild the carburetor with genuine Mikuni kits.

Replace the oil lines.

Questions:

Some of these questions fall into the category of is it worth it and the others are how do I do it. My questions are:

1. What should I look for when evaluating it for repair? Is there a checklist somewhere?

2. Is it worth rebuilding?

3. What is the estimated value as it sits now?

4. What would the estimated value be running?

5. What else needs to be done?

6. Any other words of wisdom that you do not mind sharing?

I appreciate everyone's time.

Thanks,

nT