Girkyman

Member

Hi All,

New to the forum but have been non-logged in creeping since I got the idea to pick up a few PWC's. I have never owned a PWC before but I love wrenching on my own stuff.

Found a pair of XP Limiteds with a trailer for (what i thought was) a good deal so I went for it. Got them home and made room for them in the garage so I can work over the winter and had something interesting happen on the first thing I tried.

According to the previous owner they were running in August when they rode them on a small lake. She indicated one was running "rough" but still ran and the other was fine. The family lost interest so she was moving on from them. She put new batteries in them and 2 brand new covers she gave me still in the bag.

On the first boat, which was the one that she said was running good, first thing I tried was to turn it over after I topped off the batteries and it wouldn't turn over. I pulled the plugs to see what was going on and when I clicked that start button it turned over this time, and brown, murky water shot out of both cylinders. I was hoping to not have to do engine rebuilds but thought maybe a top end would be needed due to the age of these things. I have yet to try to start the second one

I was hoping to not have to do engine rebuilds but thought maybe a top end would be needed due to the age of these things. I have yet to try to start the second one

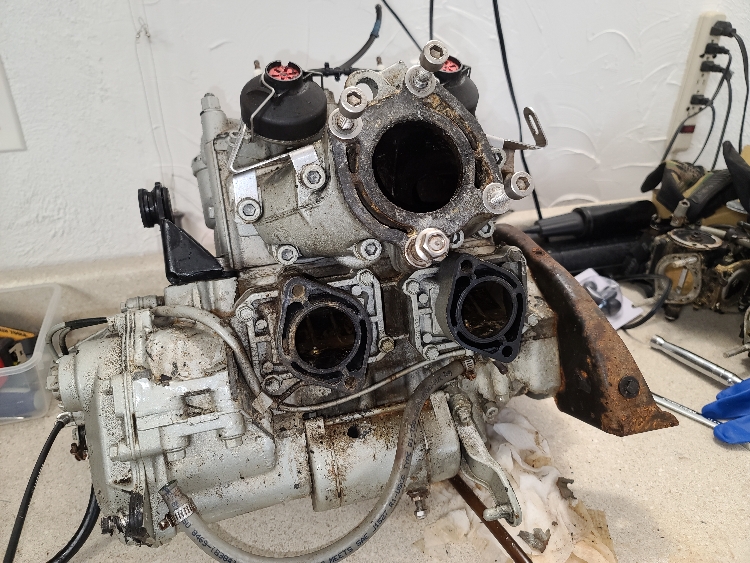

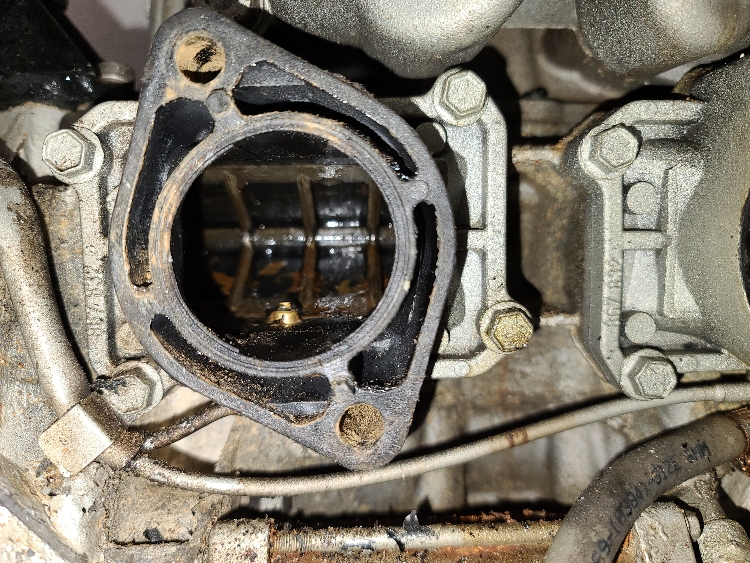

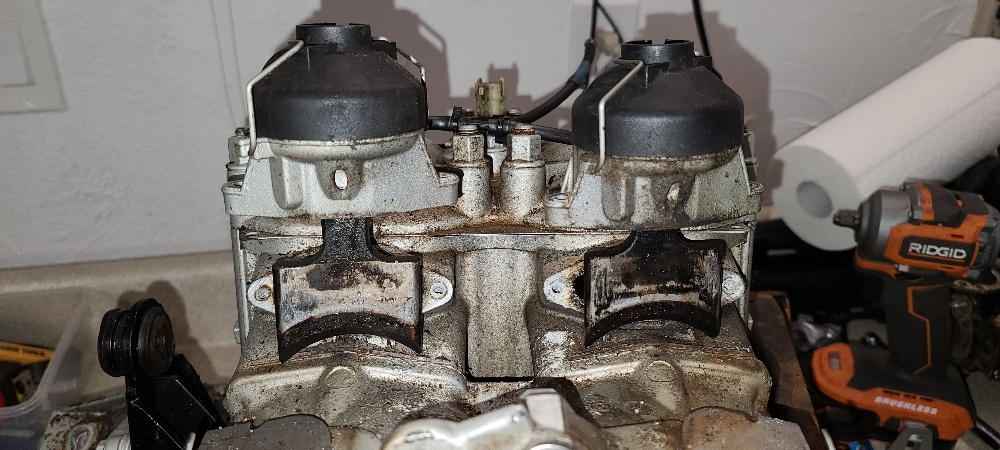

I'm going to start disassembly soon but I just wanted to throw this out there to a well informed crowd and get some opinions on what direction I should take to make sure I get a reliable boat after this rebuild and to see how deep I might have to go as far as fixing this "water" issue and also any thoughts on what might have caused both cylinders to fill up with quite a good amount of water (the picture is right after it happened but it shot out hard and bounced off the side of the engine bay and got all over me) The engine did turn over so I turned it over a few more time until nothing came out then I blew some air in there to clear out any remaining water.

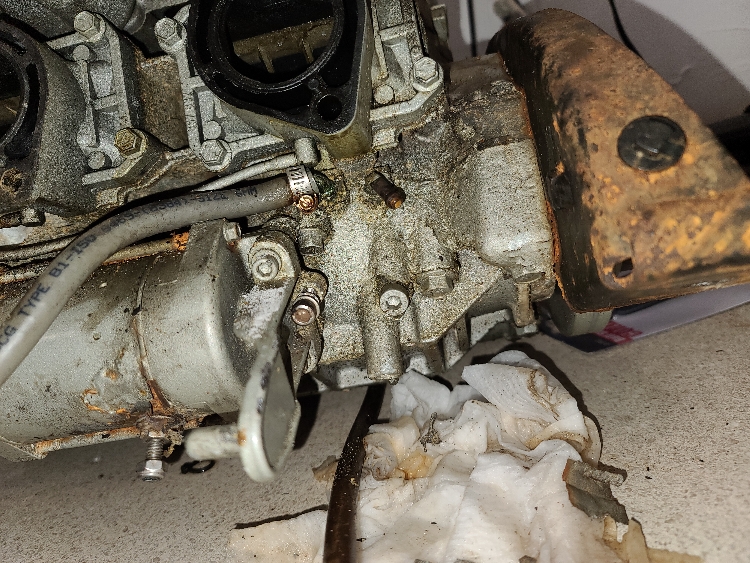

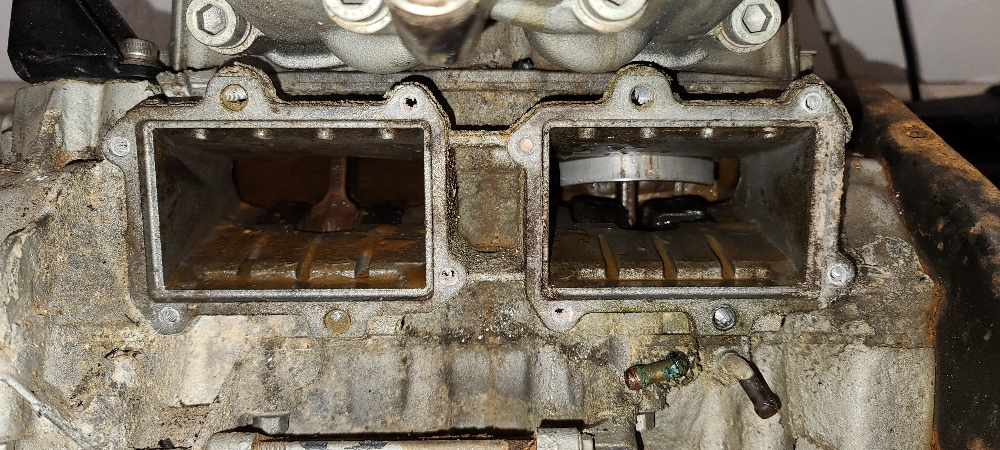

My Next step was going to pulling the carbs (in anticipation of a rebuild), pulling the exhaust, and finally the heads to get a look at what damage that water caused, and then see how everything else looks from there.

I plan on updating this thread with progress and pics and hopefully by the time the nice weather rolls around I'll be out on the water enjoying them!

Thanks,

Jared

New to the forum but have been non-logged in creeping since I got the idea to pick up a few PWC's. I have never owned a PWC before but I love wrenching on my own stuff.

Found a pair of XP Limiteds with a trailer for (what i thought was) a good deal so I went for it. Got them home and made room for them in the garage so I can work over the winter and had something interesting happen on the first thing I tried.

According to the previous owner they were running in August when they rode them on a small lake. She indicated one was running "rough" but still ran and the other was fine. The family lost interest so she was moving on from them. She put new batteries in them and 2 brand new covers she gave me still in the bag.

On the first boat, which was the one that she said was running good, first thing I tried was to turn it over after I topped off the batteries and it wouldn't turn over. I pulled the plugs to see what was going on and when I clicked that start button it turned over this time, and brown, murky water shot out of both cylinders.

I'm going to start disassembly soon but I just wanted to throw this out there to a well informed crowd and get some opinions on what direction I should take to make sure I get a reliable boat after this rebuild and to see how deep I might have to go as far as fixing this "water" issue and also any thoughts on what might have caused both cylinders to fill up with quite a good amount of water (the picture is right after it happened but it shot out hard and bounced off the side of the engine bay and got all over me) The engine did turn over so I turned it over a few more time until nothing came out then I blew some air in there to clear out any remaining water.

My Next step was going to pulling the carbs (in anticipation of a rebuild), pulling the exhaust, and finally the heads to get a look at what damage that water caused, and then see how everything else looks from there.

I plan on updating this thread with progress and pics and hopefully by the time the nice weather rolls around I'll be out on the water enjoying them!

Thanks,

Jared