Girkyman

Member

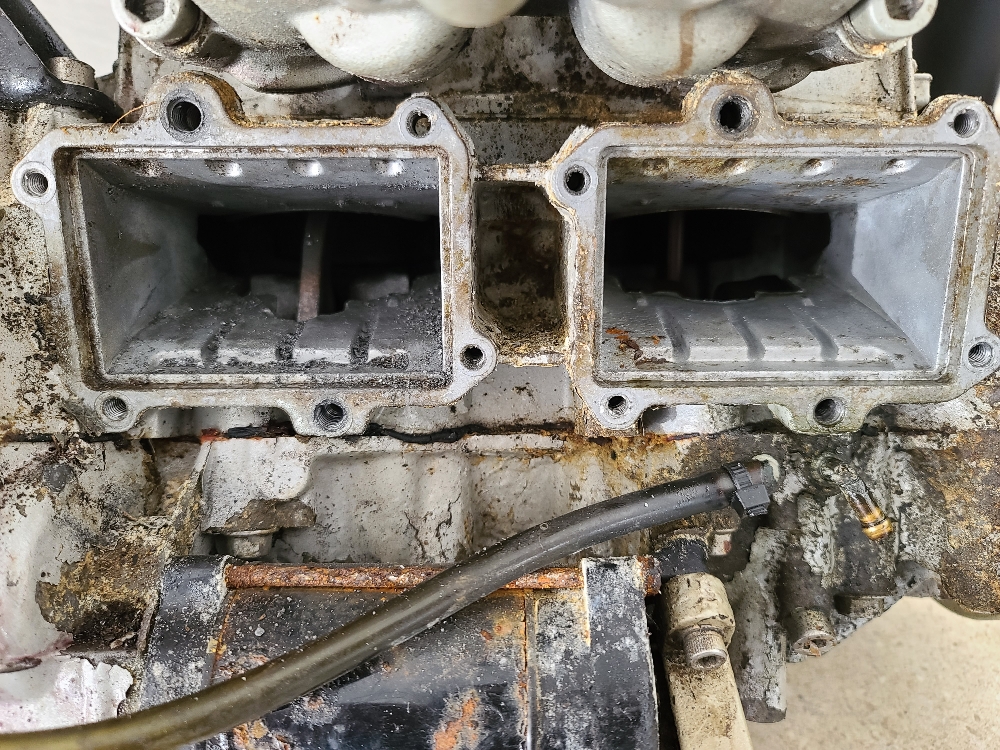

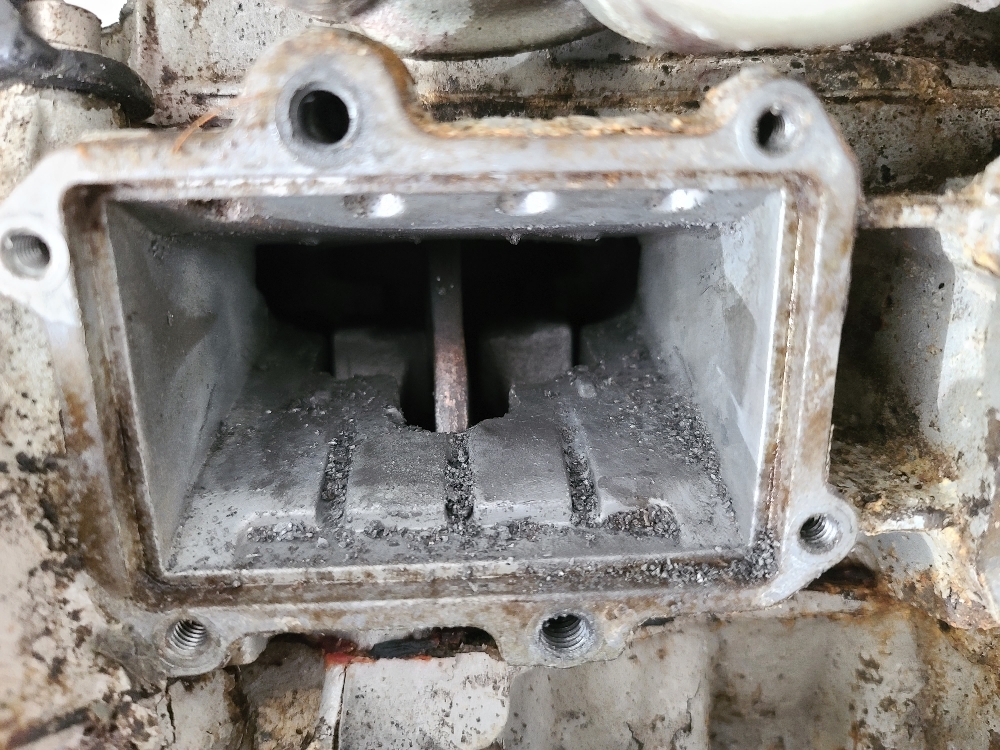

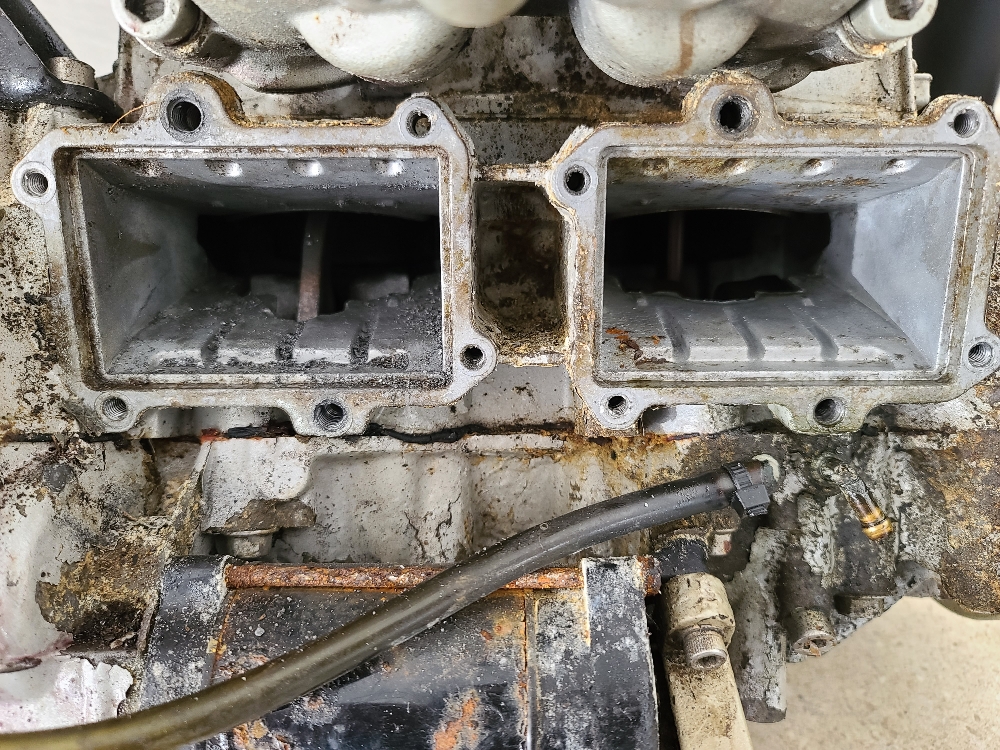

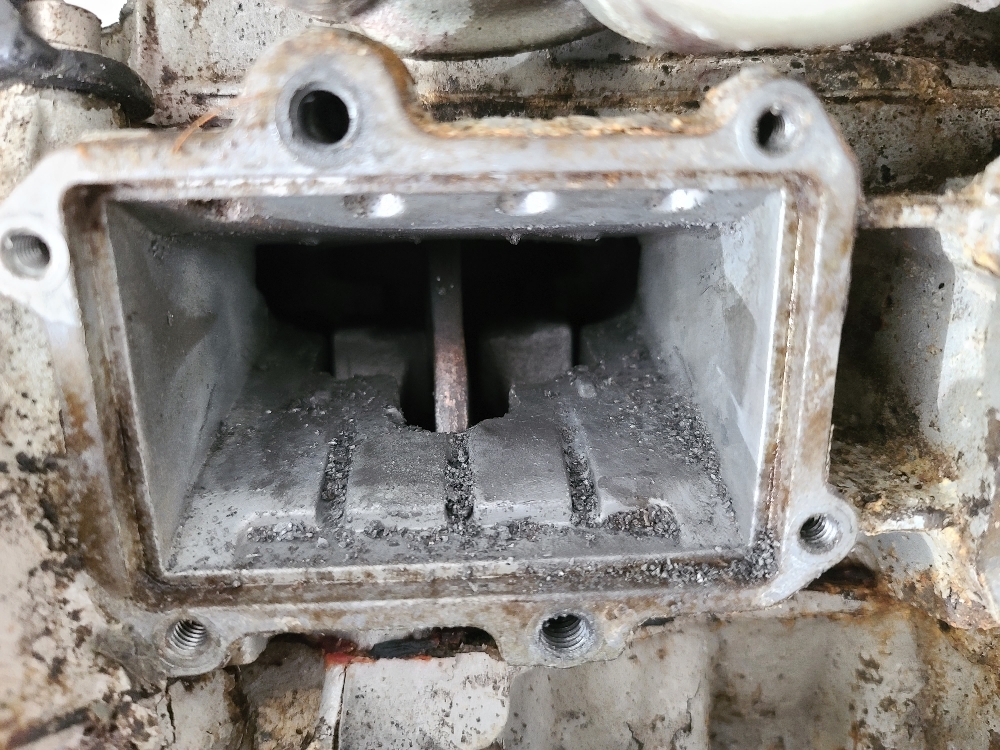

Another update on the project.... Finally got a nice day on the weekend and got the second engine pulled today and found some interesting stuff. One of the Pistons seem to have broken a rod and there was a whole lot of debris floating around.

I was wondering why the starter wouldn't turn it over....haha.

Most exciting.

I was wondering why the starter wouldn't turn it over....haha.

Most exciting.