BizzleMalaka

Member

I was taking the carbs off my new to me 98 GTX limited today when I stupidly yanked on the pulse line and broke the 90 degree nipple on the pump cover…

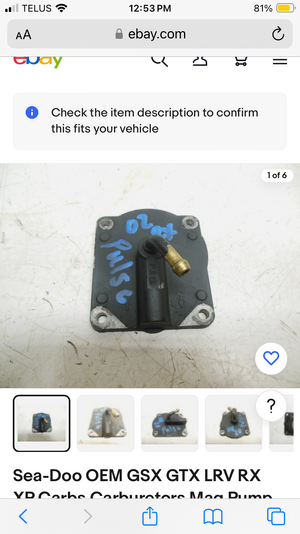

Used covers are $100 usd on eBay and new seem to be discontinued.

So I drilled out the pressed in fitting with gradually increasing drill bit sizes.

I found a 1/4” barbed fitting with small enough threads at Canadian Tire and grabbed some red lock tight.

I had to drill the hole a bit wider for the fitting and I couldn’t find a tap to match the threads so I just reamed the hole with the drill a bit so it had a slight taper then slathered the threads with lock tight and cranked it in until it was tight.

I couldn’t find a 90 degree but I think there’s room for the hose to curve around, and I didn’t have to worry about it pointing the wrong way when it got tight.

I haven’t put things back together yet and I may add some JB weld for peace of mind but what do y’all think?

Used covers are $100 usd on eBay and new seem to be discontinued.

So I drilled out the pressed in fitting with gradually increasing drill bit sizes.

I found a 1/4” barbed fitting with small enough threads at Canadian Tire and grabbed some red lock tight.

I had to drill the hole a bit wider for the fitting and I couldn’t find a tap to match the threads so I just reamed the hole with the drill a bit so it had a slight taper then slathered the threads with lock tight and cranked it in until it was tight.

I couldn’t find a 90 degree but I think there’s room for the hose to curve around, and I didn’t have to worry about it pointing the wrong way when it got tight.

I haven’t put things back together yet and I may add some JB weld for peace of mind but what do y’all think?