PGHMAN

Active Member

Yep, the exhaust and intake manifolds are blocked. The odd thing is when I remove the hose blocking the elbow on the exhaust manifold it's retaining pressure but it's not getting back to the gauge that's connected to the cylinder head cover.To do a leak test... you have to bolt on covers over the manifolds. Did you do that?

As we know the top end test routes through the cylinder cover/head into the cylinder wall jacket to the exhaust manifold. That's where I am stumped on why I can have pressure on the low end of the manifold and not back on top.

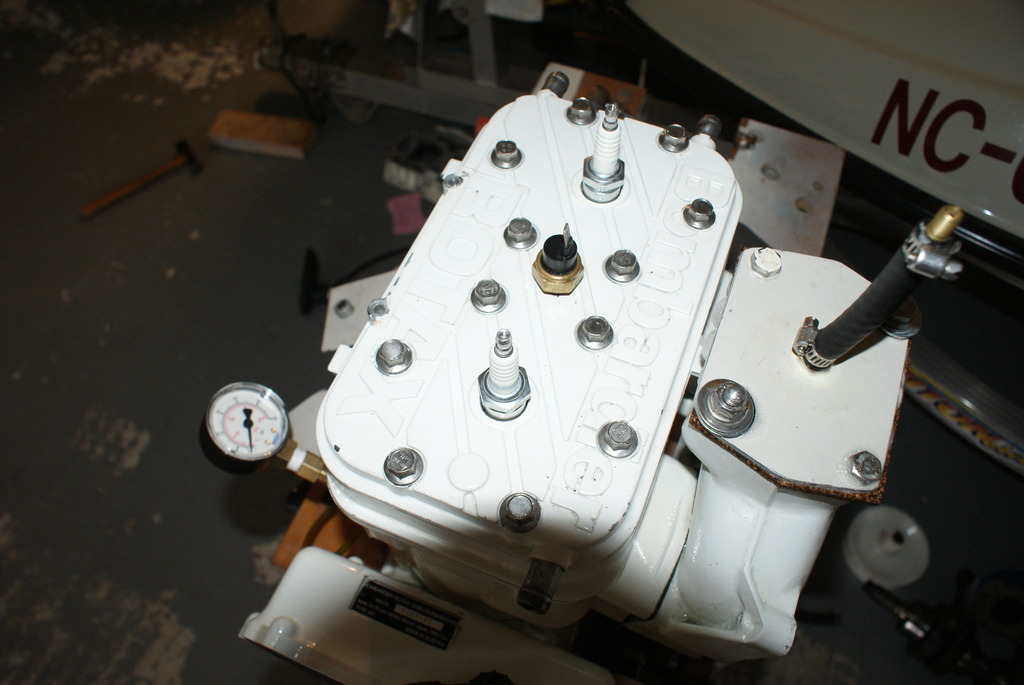

I'll post some pics later.....losing sleep on this one.