I posted this same question on another site but have got no response. I am looking for a winter project and thought I might try this.

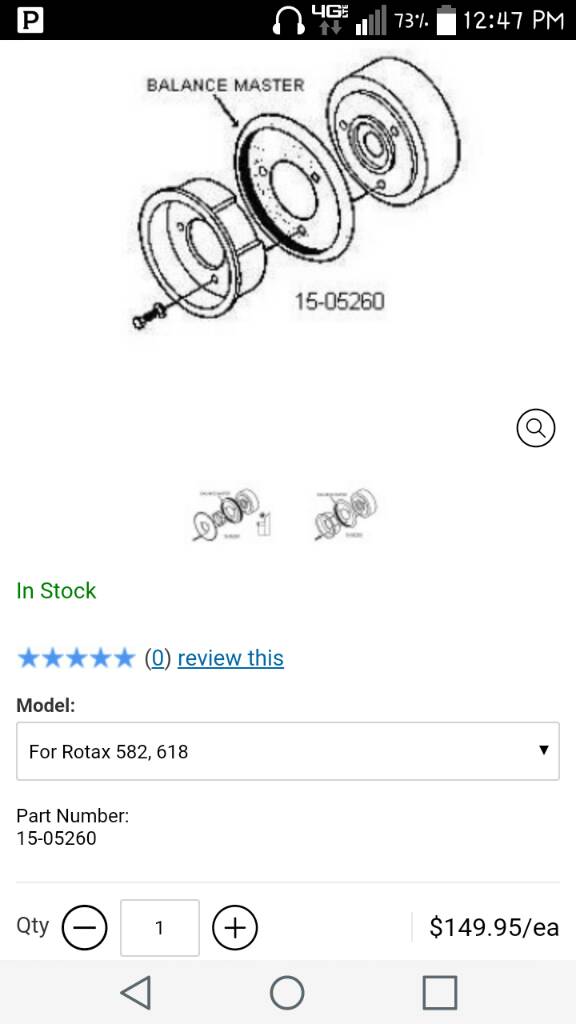

Following a series of ultralight crashes it was determined that the Rotax 582 crankshafts were prone to early failure from vibration induced stress. Bombardier introduced a fluid-bearing damper and was required on all 582 engines after 1991.

The part was designed to be able to retrofit existing engines. From what I've read due to the lack of a counter balance shaft the 717 suffered similar crank stress at high rpms. Some ingenious racer's in the PWC community started using the 582 damper on 717 engines to prolong crank life and reduce vibration.

If I understand correctly the 717 PTO has to be lathed to remove the extra mass & protruding lip. Perhaps a 580 PTO would be easier to lathe to a smaller circumference. The PTO then has three mounting holes drilled and tapped. The Rotax 582 damper mounts to the smaller, drilled 717 PTO. The result is significantly reduced vibration and longer crank bearing life.

The Rotax 582 dampers are fairly inexpensive to buy. It is also recommended to replace OEM Mag flywheel with a lightweight design. Had anyone done this before? Can somebody provide me with more information?

Following a series of ultralight crashes it was determined that the Rotax 582 crankshafts were prone to early failure from vibration induced stress. Bombardier introduced a fluid-bearing damper and was required on all 582 engines after 1991.

The part was designed to be able to retrofit existing engines. From what I've read due to the lack of a counter balance shaft the 717 suffered similar crank stress at high rpms. Some ingenious racer's in the PWC community started using the 582 damper on 717 engines to prolong crank life and reduce vibration.

If I understand correctly the 717 PTO has to be lathed to remove the extra mass & protruding lip. Perhaps a 580 PTO would be easier to lathe to a smaller circumference. The PTO then has three mounting holes drilled and tapped. The Rotax 582 damper mounts to the smaller, drilled 717 PTO. The result is significantly reduced vibration and longer crank bearing life.

The Rotax 582 dampers are fairly inexpensive to buy. It is also recommended to replace OEM Mag flywheel with a lightweight design. Had anyone done this before? Can somebody provide me with more information?