red2blue

New Member

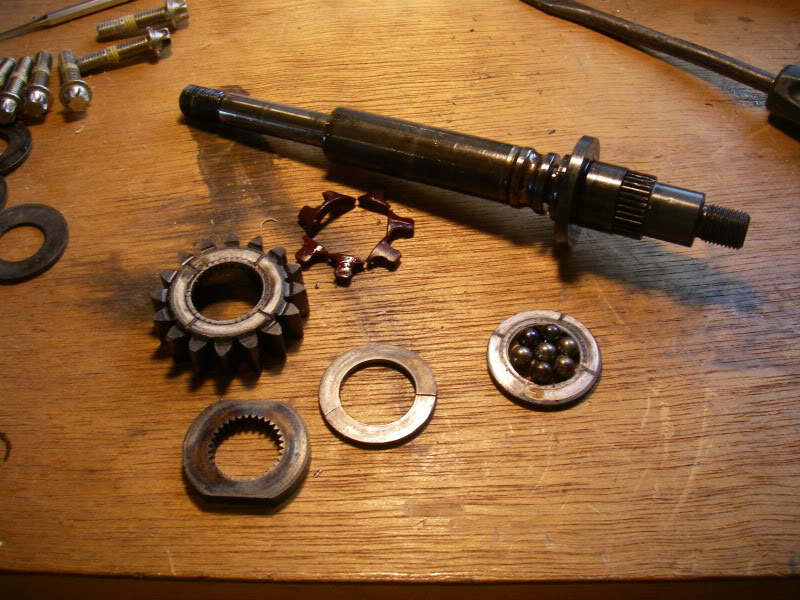

I counted 5 washers still on the shaft...gear is awfully centered for needle bearings to be gone.

Looked like a wheel touch down. I'd disassemble that sc/shaft and start counting. See if you can't account for all the missing pieces...otherwise...if you can't...then it'll be time to start some major cleaning.

now..the diff in pics between yours and mine ....the space between your washers...and the shaft on mine showing misalignment because the top bearings all rolled to one side.

Point being...you still have 5 washers on your sc shaft.

Looked like a wheel touch down. I'd disassemble that sc/shaft and start counting. See if you can't account for all the missing pieces...otherwise...if you can't...then it'll be time to start some major cleaning.

now..the diff in pics between yours and mine ....the space between your washers...and the shaft on mine showing misalignment because the top bearings all rolled to one side.

Point being...you still have 5 washers on your sc shaft.

Last edited by a moderator: