-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My FIRST 97 SEADOO GSX PROJECT.

- Thread starter sselzer

- Start date

- Status

- Not open for further replies.

515 in the cylinder groove where the black O ring goes in, then install the O ring in that groove. Put the red O rings on and then install head. Put Loctite 242 under the head of the bolts and molycote 111 (synthetic grease) on the threads of the head bolts.

Right on Kicker, sounds familiar-- SS go back a page and check your thread and scroll down. It was all laid out for you.

http://www.seadooforum.com/showthre...OO-GSX-PROJECT&p=306821&viewfull=1#post306821

Right on Kicker, sounds familiar-- SS go back a page and check your thread and scroll down. It was all laid out for you.

http://www.seadooforum.com/showthre...OO-GSX-PROJECT&p=306821&viewfull=1#post306821

Just wanted to double check, I have made a few costly mistakes and wanted to make sure I understood correctly.

Jetskigoodies

Well-Known Member

This is a pretty big project you have taken on. It looks like you have most of it back togethor. Did you ever buy a manual? Every bolt must be torqued back to spec. I havent seen you mention anything anout looking through your manual. I just want to make sure after all this work you dont have a problem with bolts being too loose or too tight.

Jetskigoodies

Well-Known Member

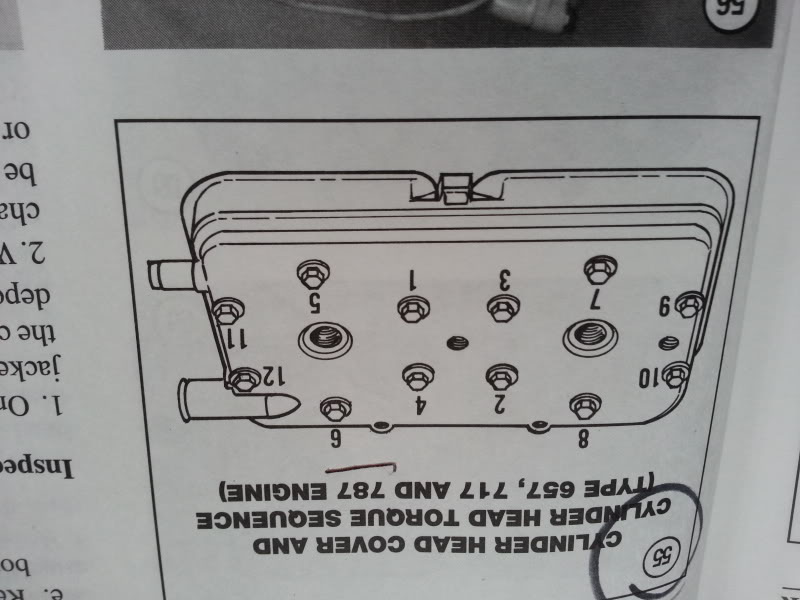

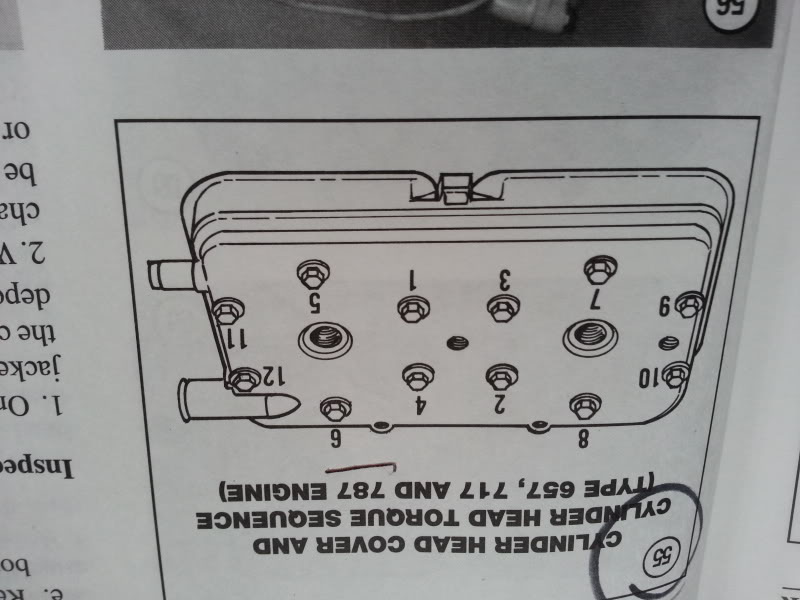

Here is the order to torque that back down

Here is the threadlocker you need

Here is the threadlocker you need

I have one of those manuals, but they cover several models and engines, so sometimes I post things just to make sure I'm not making a mistake, for instance using info for a 720 engine. Also I brought a barely used engine, that was complete. I customized few things in green and replainted the rest of the engine. I'm sorry if I repeat things or ask stuff that's in the manual, but after screwing up the jugs on the first engine I'm always double checking.

Jetskigoodies

Well-Known Member

It shouldnt be a problem, post a picture. A little pitting is fine

Here are some pictures:

View attachment 17235View attachment 17236View attachment 17237View attachment 17238

Is the pitting too bad or is will it be alright to use raves?

bigJake

Well-Known Member

I notice that I can easly pull the shaft that attachs to engine out, the engine isn't installed yet, is there a issue when the shaft just glides out of the pump area? Should it be secured?

if you are talking about the drive shaft between the PTO and the pump, no it is not secured. Just splines on both ends that fit into the pto and the pump. make sure you don't lose the rubber bumpers off the ends of the shaft.

kicker

Well-Known Member

Here is a pic of 2 and 26 that racer referred to. There is no way to grease that spline, so I am assuming that it should be packed with grease at assembly, can someone confirm that? I am doing the same thing next week, hence the pictures.

I have been trying to catch up with SS but he is always a step ahead. :lol:

.

I have been trying to catch up with SS but he is always a step ahead. :lol:

.

Last edited by a moderator:

There is no way to grease that spline, so I am assuming that it should be packed with grease at assembly, can someone confirm that?

Yep....... That is what #16 is

Do I need an alignment tool to reinstall the engine if I didn't touch the two engine mounts near the rear?

This has been beat to death lately but there are two camps of thought here, some say yes, some say no. I'm in the YES camp.

Jetskigoodies

Well-Known Member

I have my tent set up and cooler full of beers at the same camp as Racer.

68ragtop

Well-Known Member

The engine had never been removed from my GSX. When I bought it, I had the drive out so while i was at it, I checked the engine alignment. I ended up shimming the entire engine up, & even more so in the front to get it perfectly aligned. Now I recently picked up another project. this ski has every original oetiker clamp on it (except the carbs), so I am assuming the engine has never been out either. I'll check the alignment, & I am going to guess its not exactly where it should be. So, I would even go as far as too say even the untouched ones are probably not perfect, then if you take things apart it only gets worse.

Now that I invested into the tool, I really can't see another way to do it. My first ski I bought with the engine in a box. I used every thing I could think of to align the engine & It still had a vibration. Bought the tool, & found I was not very close with my survivor method.

I would at least consider what was suggested by a member here last year. Have a machine shop cut a shaft for you & slide it though your mounted pump housing with the impeller shaft removed. We can give you the sizes if you need them.

The pump housing allows the shaft to wiggle a little more than the tool does, but will still get you where you need to be at an economical cost.

Now that I invested into the tool, I really can't see another way to do it. My first ski I bought with the engine in a box. I used every thing I could think of to align the engine & It still had a vibration. Bought the tool, & found I was not very close with my survivor method.

I would at least consider what was suggested by a member here last year. Have a machine shop cut a shaft for you & slide it though your mounted pump housing with the impeller shaft removed. We can give you the sizes if you need them.

The pump housing allows the shaft to wiggle a little more than the tool does, but will still get you where you need to be at an economical cost.

- Status

- Not open for further replies.

Similar threads

- Replies

- 9

- Views

- 360

- Replies

- 30

- Views

- 1,151

- Replies

- 15

- Views

- 489