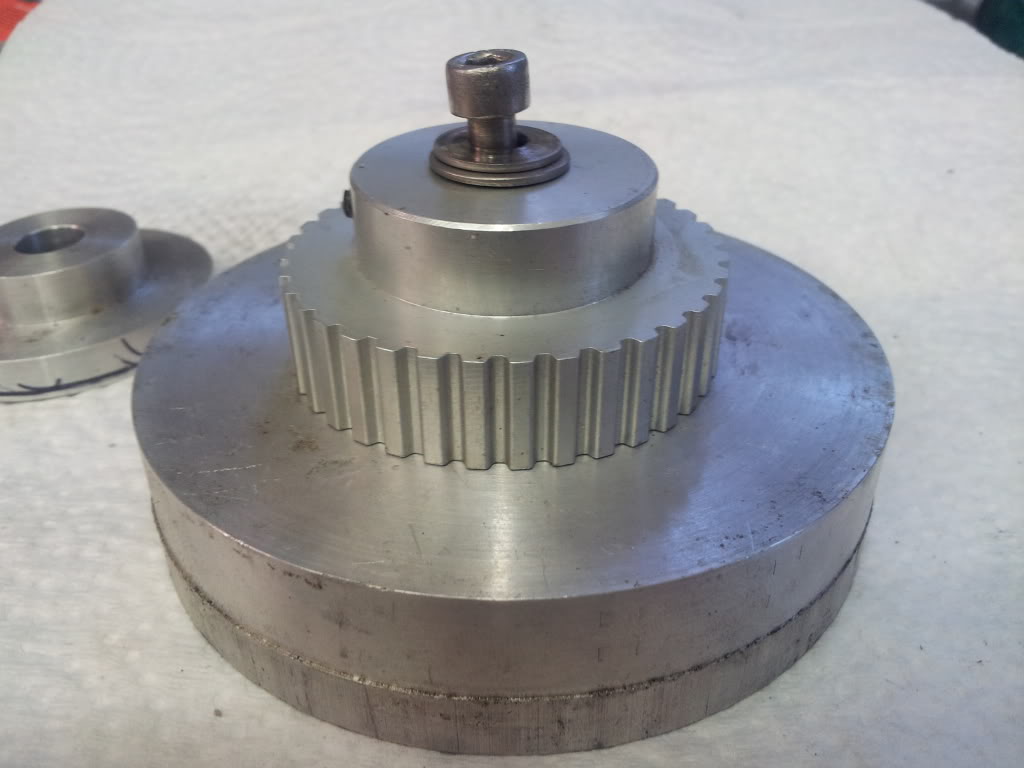

It was just the angle or the seals...that gear is fine. Once a gear i stripped like that the experts have always said the shaft is bent/out of spec. I have a few ready to go if you need one.

The hard part about making your own is finding a long 10mm bolt that is full thread. The tool is only about $20 so I bought one.

The hard part about making your own is finding a long 10mm bolt that is full thread. The tool is only about $20 so I bought one.