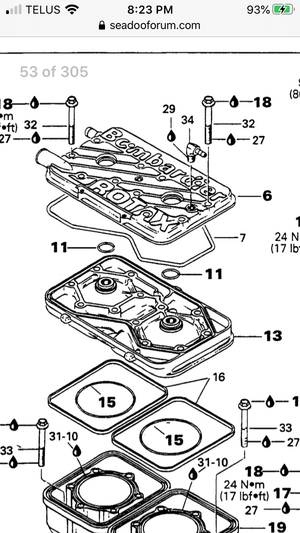

Ok I see this is a topic that’s both discussed and confusing. Going to put the top ends (93 XP, 94XP, 96SP) back together and I see conflicting info. Looks like the specs I saw only call for grease. But I see a lot about blue loctite. Either under the bolt head or on the threads with grease being vise versa. Which should I be doing?

Head/Cover bolts

- Thread starter EvoV98

- Start date