Sorry IDoSeaDoo, nice catch, I revised my post to indicate counterbalancer seal and not labrynth seal.

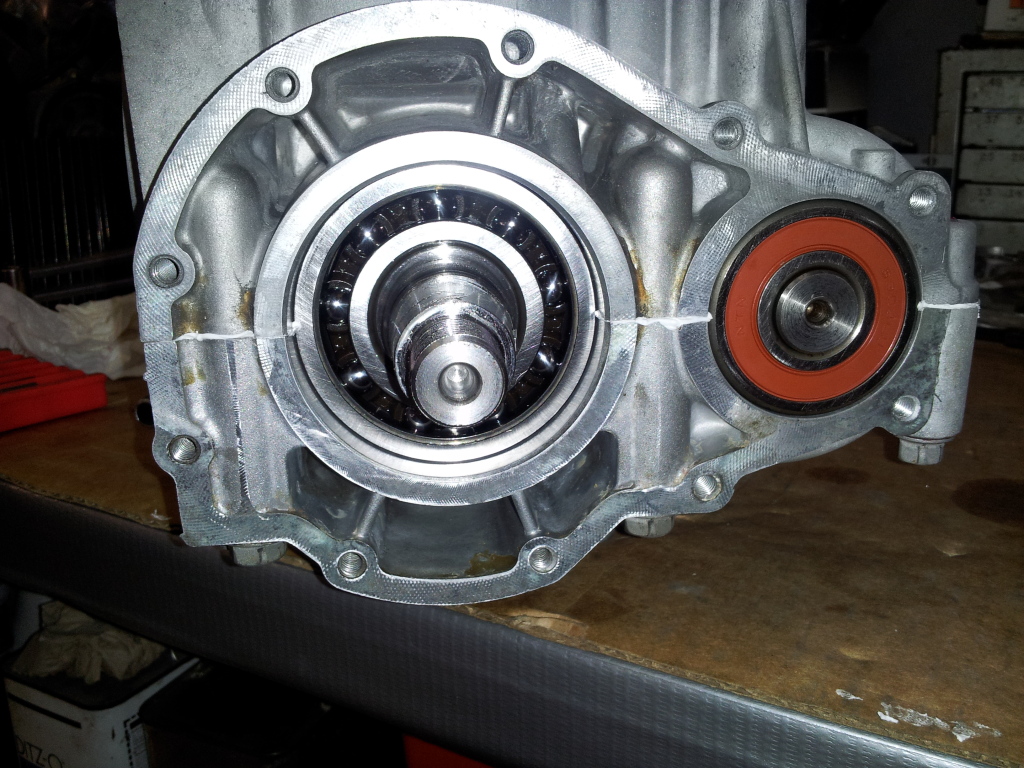

The oil/air/fuel mixture is more than enough to lubricate the bearings and gears of the crank and counterbalancer. Every oil injected or premixed two cycle engine made uses this form of lubrication. If it is good enough for the crank bearings why not for the counterbalancer. This is one of the reasons they use ball bearings and not flat babit bearings like in a car. They only need a very small oil film to lubricate them not pressurized oil like a car crankshaft.

The oil/air/fuel mixture is more than enough to lubricate the bearings and gears of the crank and counterbalancer. Every oil injected or premixed two cycle engine made uses this form of lubrication. If it is good enough for the crank bearings why not for the counterbalancer. This is one of the reasons they use ball bearings and not flat babit bearings like in a car. They only need a very small oil film to lubricate them not pressurized oil like a car crankshaft.