IDoSeaDoo

Well-Known Member

I finally got around to installing my depth finder. I put it right behind the steering wheel, where the fuel gauge used to be. I figure depth is the most important thing to know. This forced me to move the vts gauge over by the cup holder.

It reads pretty well until I'm going fast. I believe the transducer just needs to be lowered some more. I think it comes out of the water.

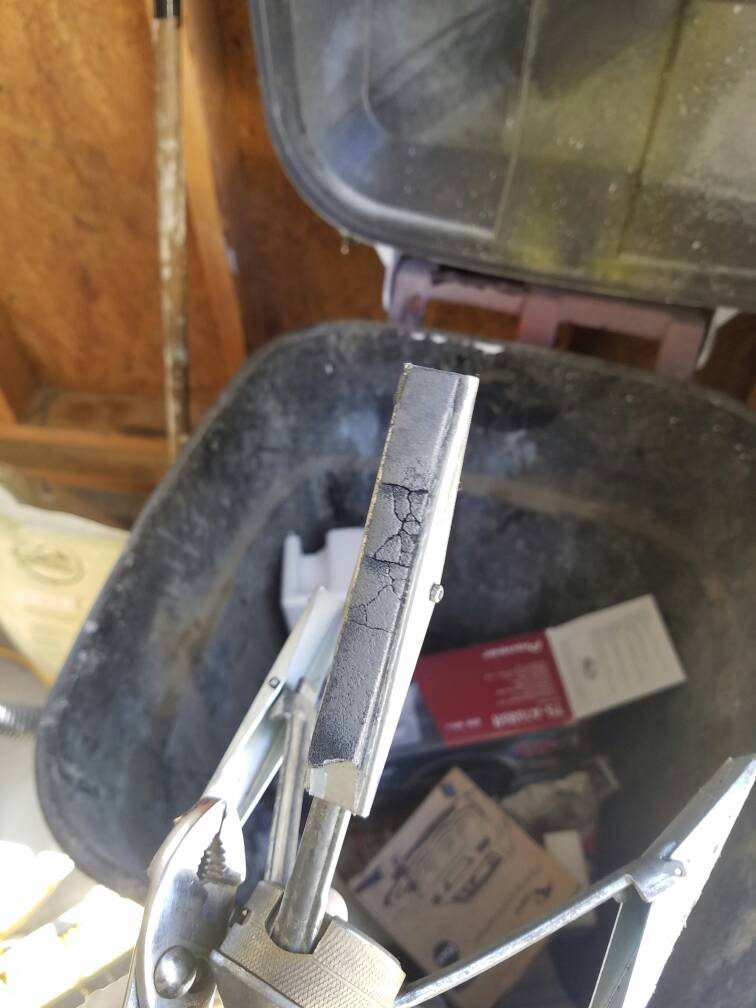

I also tried to widen my steering nozzle, but for whatever reason, doing this nozzle killed my hone stones really quickly. They lost their shape in the middle where she nozzle started to get narrow. I only managed to widen it to 87mm, making it only 3mm wider than the reduction nozzle. This did make anoticeable difference, but there is still a lot of water being reflected out of the steering nozzle.

Regardless, we had the boat out all weekend pulling tubes, wake boards and jumping waves. Good times

It reads pretty well until I'm going fast. I believe the transducer just needs to be lowered some more. I think it comes out of the water.

I also tried to widen my steering nozzle, but for whatever reason, doing this nozzle killed my hone stones really quickly. They lost their shape in the middle where she nozzle started to get narrow. I only managed to widen it to 87mm, making it only 3mm wider than the reduction nozzle. This did make anoticeable difference, but there is still a lot of water being reflected out of the steering nozzle.

Regardless, we had the boat out all weekend pulling tubes, wake boards and jumping waves. Good times