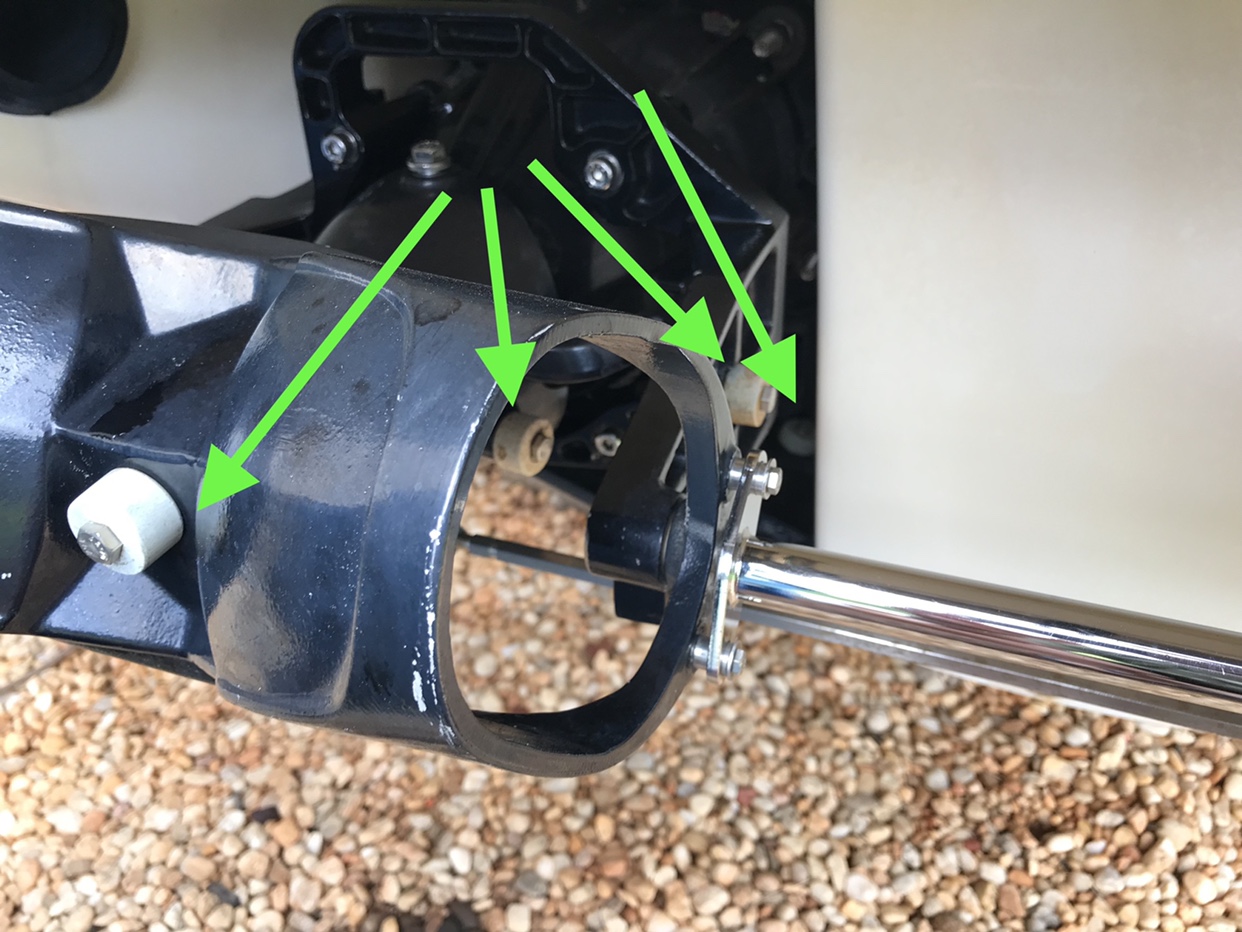

I had the same problem since my Speedster 200 is run in salt water. I had to cut the heads off the Allen bolts to get the gate support off. The bolt heads are counter sunk into the gate support so I had to destroy the gate support too. I purchase a new gate support from Amazon.com -- $200. I used an angle grinder with a cutoff wheel and it cut the bolt heads like butter. Yank off the gate support. Then use a

1/4" to 1/2" Stud Extractor tool to remove the studs from the pump. You may need to add some heavy-duty heat with a welding torch.

I purchased a 5-pack of

M8x120mm 1.25mm Pitch Stainless Steel Hex Socket Head Cap Screws 5pcs from Amazon.com -- $10.61. You will need to purchase the correct bolt length for your boat. My smaller Speedster 150 uses 110 MM bolts. During reassembly do NOT use any thread locking locktight on the bolt threads. Purchase three M8 stainless nylon locking nuts from your local hardware store and use on the back side of the bolts to lock the bolts in. You may only be able to attach nuts to 3 of the bolts. It should be fine. Use plenty of Marine grade antiseize compound on the bolts when reassembling so you will not have this problem the next time you want to remove your jet drive. I check the drive bolts occasionally while the boat is on the trailer to ensure they are tight.

I hope this helps.