kicker

Well-Known Member

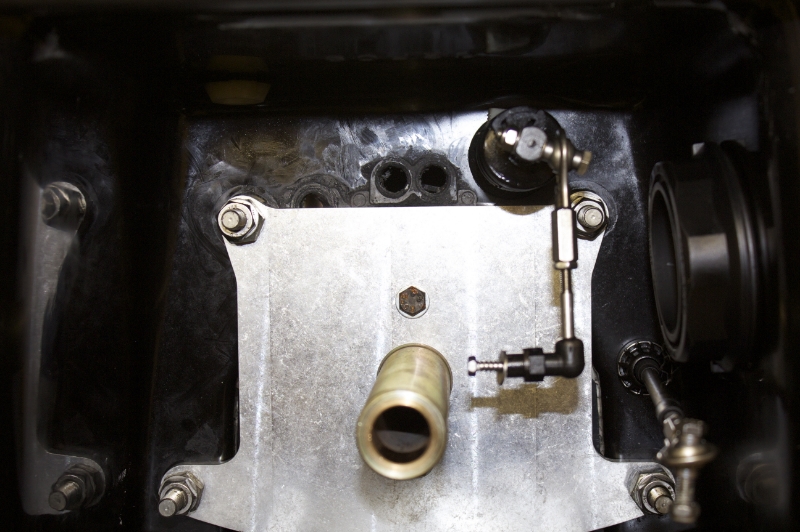

I'm a little stumped with this one. My carbon seal is worn on an angle, so bad that the shaft wore an oval hole in the middle of the carbon seal. It is not even close to lining up with the ring carrier on the shaft. The carbon seal hangs much lower then the SS ring. In the pictures you can see how far out it is, and the dug out oval from the driveshaft rubbing.

I figured the motor was out of alignment, so I installed the alignment tool, the problem is according to the alignment I have to raise the motor a bit to line it up. That in turn will raise the SS ring on the driveshaft making my problem even worse as far as getting the carbon seal and SS ring to line up. When I put the alignment shaft through the thru hull fitting, the shaft almost hits the top of the fitting.

My question is, what is so far out of alignment? Could the thru hull fitting be that far out of wack. It seems to be too low and on a downward angle. Or am I doing the alignment wrong? On the GS models the alignment tool bolts to the complete pump housing, but I notice on the X4 the tool bolts flush to the back of the hull of the ski. Am I missing something here?

I figured the motor was out of alignment, so I installed the alignment tool, the problem is according to the alignment I have to raise the motor a bit to line it up. That in turn will raise the SS ring on the driveshaft making my problem even worse as far as getting the carbon seal and SS ring to line up. When I put the alignment shaft through the thru hull fitting, the shaft almost hits the top of the fitting.

My question is, what is so far out of alignment? Could the thru hull fitting be that far out of wack. It seems to be too low and on a downward angle. Or am I doing the alignment wrong? On the GS models the alignment tool bolts to the complete pump housing, but I notice on the X4 the tool bolts flush to the back of the hull of the ski. Am I missing something here?